metal i-beam house cost Metal building costs are calculated on a square-foot basis. On average, kit packages cost $15 to $25 per square foot. However, once installed, the cost can increase to between $24 and $200 per square foot, depending on .

BBB Directory of Sheet Metal Fabrication near West Creek, NJ. BBB Start with Trust ®. Your guide to trusted BBB Ratings, customer reviews and BBB Accredited businesses.

0 · red iron i beam cost

1 · i beam metal building kits

2 · cost of steel i beam

3 · cost of steel beams per foot

4 · cost of steel beam installation

5 · cost of i beam installation

6 · 10' steel i beam price

7 · 10' i beam price

What is Oxy-Acetylene Welding? Oxy-acetylene welding depends on ignited oxygen and acetylene gas to produce flame that is capable of melting and fusing metals. Depending on the flame control, it is easy to change the heat and therefore use the technique for cutting, welding, and repair.

Metal buildings run around - per square foot for materials delivered, but we don’t recommend relying on a per SQFT price. Learn more about the many factors that influence the overall cost per square foot in the post linked below.From our premium I-beam buildings that deliver the highest quality building .

Browse steel building specials for unbeatable prices on our most popular .

hillsborough county electrical code breaker boxes requirements

"When I built my house in 2003, I put in a 400 amp service knowing that I was .Metal Building Homes. Recommended Use: 1 Bedroom, 2 Bedroom, 3 Bedroom, 4 .Metal building costs are calculated on a square-foot basis. On average, kit packages cost to per square foot. However, once installed, the cost can increase to between and 0 per square foot, depending on . Steel I-Beam Cost. A steel beam costs 0 to 0 per foot to install or ,200 to ,200 on average for residential construction. Replacing a load-bearing wall with a support beam costs ,000 to ,000. Steel I-beam .

How Much Do Metal Building Homes Cost? (2024 Prices) Boydton, VA. How much do metal building homes cost? – 5 cost per square foot (finished) 0,000 – 0,000 average cost to build a 40x60 home (2,400 .

red iron i beam cost

The cost of steel beams, according to HomeGuide, for residential construction is 0 to 0 per foot installed or ,200 to ,200 on average. Replacing a load-bearing wall with a support beam costs ,000 to ,000 . S teel I-beam installation costs around ,200, on average, but prices can fall anywhere between ,000 and ,000, depending on the length of the beam you need and whether you’re including it as part of new construction .

Installing steel beams costs between ,253 and ,347 (including labor) for most homeowners, with an average cost of ,284.The price varies and depends on the size and span of the brand beams and posts. Expect a higher project .Metal building prices and cost guide for 2024. Prefab metal building kits range in price from to per square foot.. On average, installed (turnkey) steel buildings cost to per sq. ft., covering the kit, concrete slab, delivery, .

The cost of the beam probably the smallest part of this job. Hiring an engineer to do load calculations and drawings for the permit, moving electrical and hvac ducts from the existing wall, matching the flooring, ripping up the basement floor and ceiling to pour new footers and add new support columns as well as finishing the drywall and painting to match are going to be very costly.

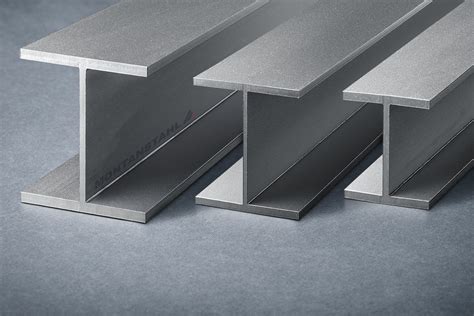

The total cost to install a steel beam usually ranges from ,200 to ,200 when considering the beam’s length, installation complexity, labor, delivery, and permits. Steel I-Beam Cost. Steel I-beams are a popular choice due to their . I Beams are typically manufactured using two main processes: Hot Rolling: in this method, rectangular billets or steel slabs are heated to a high temperature and passed through a set of shaped rollers, moulding the heated steel into the desired I Beam shape.. Welding: I Beams can sometimes be manufactured by welding together three steel plates to form the I shape.

What sets I-Beam buildings apart from traditional construction is its versatility, cost efficiency, accelerated construction time, custom engineering, and sustainability. Be proud in knowing that your steel building will be 100% made from American steel and trust that Coastal Steel Structures can deliver our buildings nationwide.

* Building Permits: Local building codes may have specific requirements for both steel and wood structures. * Availability of Materials: Check the availability and cost of materials in your area. * Professional Help: Consider hiring professionals for tasks like foundation work, electrical wiring, and complex insulation projects.Not too long ago, we wrote a blog about structural steel as a building material and the importance of it. Since then, questions have been flowing in surrounding the topic. . In general, steel I beams can cost - per foot in materials. This could end up .30x60 Metal building - custom steel kits and cost guide. Our 30x60 metal building packages are manufactured from American steel, designed to weather the harshest environments, and engineered to last. They have warranties of 30+ years and virtually zero maintenance. . including pre-drilled primary steel I-beam framing and secondary framing .

Rigid frame steel building homes cost. A rigid frame or I-beam building costs to 5 per square foot fully installed and finished. The strong steel frame is designed for heavy snow loads and column-free interior spaces. A-frame metal building homes cost. An A-frame home costs 0 to 0 per square foot for a fully finished metal house .Probably because in 800 years the rest of the building will dissolve away, finally exposing it to the elements and reducing the strength slightly . It was probably some website selling some miraculous rust inhibitor or stainless steel beams. Whatever it was it was ridiculous! . only costs a few dollars more a foot but looks more .

hills roofing and sheet metal

How to use the Steel I Beam Cost Calculator. To use the calculator, enter the dimensions of the steel I beam, including the width, height, web thickness, flange thickness, and length of the beam. The density field is pre-filled with the standard density of steel (7850 kg/m³), but you can enter a different value if needed.Installing steel beams costs between ,253 and ,347 (including labor) for most homeowners, with an average cost of ,284. The price varies and depends on the size and span of the brand beams and posts. . Steel Beam House Construction Costs. The use of steel structural support beams is typically in conjunction with other support structures .The average steel I-beam cost depends on market conditions. For instance, if there’s a high supply of materials but buyers are few, the price will be lower. . For instance, a warehouse building made from steel has a price range of .Cost of Building a Metal Home in 2024: See Prices & Compare. Are you considering building your own metal home? If you are, then you’ll want to keep on reading. . which means that it won’t be interrupted by things like beams or .

40x60 metal building - custom kit packages, plans & cost guide. A 40x60 metal building is a solid choice for any property and provides 2,400 square feet of customizable space to satisfy many end uses, including shops, garages, . Steel is one of the strongest building materials known to man. Steel is mostly comprised of iron, 98%. The other 2% is a hardening agent, usually carbon. It is the carbon that makes it super strong and rust resistant. Steel I-Beam Costs # You can find a steel I-beam from your local steel supplier.

i beam metal building kits

cost of steel i beam

Direct comparison, LVL will be cheaper in most cases unless you've got high loads or long spans. An lvl beam vs a steel beam is a poor comparisons though, since it's the installation of steel that can really add up (nailers, welded connections, cranes). If you're doing a lot of engineered beams on the project, steel might make sense. An I-beam, also known as an H-beam or W-beam, is a structural beam with a cross-section that resembles the letter I.It is most commonly made from steel and used in construction to support horizontal loads along its length. Typically, an I-beam consists of two horizontal components called flanges, connected by one vertical component called the web. Harsh weather can easily damage light-weight tube framing. For a tube framed metal building to last, structural posts may need to be placed every five to eight feet. This is inappropriate for some building functions and purposes. For a metal building to really stand the test of time, other framing materials should be considered. Pros of Tube .A metal roof and walls not only provide excellent protection against the elements, but they also require less maintenance than traditional wood or other materials. Fire-resistant components add an extra layer of safety to your building. Cost-Effective. Investing in an I-beam steel building can save you money in the long run.

hillman brass metal shelf bracket

Because the I beam can carry enormous loads, it can assure the structural integrity of the structure without the need for additional structural supports, which would increase the project’s cost and construction time. I beams are cost-effective since they don’t require a lot of steel and have a wide range of uses.The cost of steel support beams varies based on length and type. For example, a 10′ steel I-beam typically costs between and 4, while a 30′ steel I-beam ranges from 4 to 2. H-beams, which are stronger and can support longer spans, can cost nearly double that of I-beams. Steel beam prices fluctuate due to market conditions.A building in Denver, for example, needs to handle heavy snow and will cost more, while a building in New Mexico doesn’t need this. The extras you add in like interior panels and insulation can also add to the price. The economy fluctuates so price quotes can change over short periods like six months. Raw material prices will also go up and .

Steel Factory Mfg arch style steel buildings are a cost effective solution to your steel building needs. The arch has been the strongest design known to man since the Roman times. Our buildings capitalize on this strength providing clearspan buildings that are inexpensive to put up, but can stand up to earthquakes, hurricanes, tornadoes, or . While the market price of metal can fluctuate, the general cost of a red iron building is between to per square foot. . the general cost of a red iron building is between to per square foot. 1-888-807-6006 [email protected]. Coverage Areas; Projects; Our Buildings. . Because red iron buildings have steel I-Beams .

cost of steel beams per foot

West Coast ASM is responsible for all the corrugated metal siding you see on the exterior of the building and parking garage. West Coast ASM installed over 7,000 square feet of pre-finished metal siding to give the building a modern look.

metal i-beam house cost|i beam metal building kits