box bending sheet metal A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these.

A sheet metal mechanic works with various thin sheets of metal materials to fabricate, install, and repair products and parts made from sheets of metal. Their direct supervisor may be a sheet metal supervisor, shop manager, production manager, or general contractor depending on their place of employment.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

F2.14 F2.13 F2.12 F2.11 F2.10 C2160 C2021 C2110 C2075 C2163 F2.24 F2.25 F2.26 . Excursion, Super Duty Series F−250, F−350, F−450, F−550 ’04 11−1 Fuse and Relay Information Central Junction Box (CJB) (14A067) PCM power relay Blower motor relay Trailer tow relay, . Auxiliary relay box 2 Auxiliary A/C relay Daytime Running Lamps .

Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan .

beer and metal fest house of blues

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan .In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables. They cover how to make SHEET METAL DOG TAGS and SHEET METAL VISE JAW COVERS.

types of bending sheet metal

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these.

It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct . How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal. Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

sheet metal bending standards

sheet metal bending near me

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

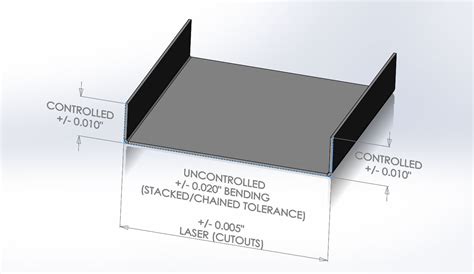

Box bending can be rather tricky with sheet metal because of the geometry of a press brake. typically the upper beam or punch holder will get in the way of very deep boxes. When bending with large returns there are a few tricks outside of just tooling selection.

Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan .

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my two previous sheet metal Instructables. They cover how to make SHEET METAL DOG TAGS and SHEET METAL VISE JAW COVERS. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these. It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct .

How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal. Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

sheet metal bending guidelines

sheet metal bending chart

Sheet metal setback refers to the distance from the bend line to the point where the metal starts to bend. It is also described as the difference between the mold line length and the flange length. Also is a crucial factor in sheet metal fabrication.

box bending sheet metal|types of bending sheet metal