sheet metal unfolding SigmaUNFOLD empowers you to recognize sheet metal bend features in a 3D body and flatten the part using accurate K-factor based calculations, which ensures a realistic, real-world representation of the part in the software. This article covers the installation and use of all boxes and conduit bodies used as outlet, device, junction, or pull boxes, depending on their use . Florida Electrical Code 2014 > 3 Wiring Methods and Materials > 314 Outlet, Device, Pull, and Junction Boxes; Conduit Bodies; Fittings; And Handhole Enclosures

0 · solidworks fold sheet metal

1 · sheet metal unfolding calculation

2 · sheet metal transition calculator

3 · sheet metal software free download

4 · free sheet metal layout patterns

5 · free sheet metal bending software

6 · free metal fabrication design software

7 · autocad sheet metal unfolding

Deep drawing reshapes flat metal sheets into hollow, three-dimensional forms. This process stretches the material over a die, creating complex shapes without seams or joints. Steps Involved in Deep Drawing Stainless Steel. The deep drawing process follows a series of .

solidworks fold sheet metal

SigmaUNFOLD empowers you to recognize sheet metal bend features in a 3D body and flatten the part using accurate K-factor based calculations, which ensures a realistic, real-world representation of the part in the software. Ever wondered how to precisely unfold sheet metal for bending? Understanding the K-factor is key. This article breaks down the calculation process, providing engineers and technicians with a practical guide to .

sheet metal unfolding calculation

Sheet Metal Design and Unfolding Software for Tees, Bends, Junctions, Intersections, Cylinders, Cones, Ducts, Flue, Diverters, Adapters, Chutes, Chimneys, Hoppers, Structural Steel and much more. See specification for .

Learn how to calculate sheet metal unfold size with our step-by-step guide. Improve your accuracy and productivity in no time!

8 Ways to Ensure Your Sheet Metal Designs Unfold. 8 Rules for Converting Solid 3D Designs to Flat Sheet Metal. Improve your sheet metal part design and reduce costs by sticking to these quick guidelines. To skilled sheet metal designers, .

You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design. Unfolded parts are not exported with the solid when you .

Unfolding of all single part sheet metal models. Bend deductions adjusted to your specific practical production, not some theoretical rules. Independent from other software, but works with any software. Easy to learn and use. Work with .You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design. The Unfold button enables when you select a single .

SPI SheetMetal software extends the sheet metal functionality of the base CAD software with proven features that save time, reduce errors, and optimally link design and fabrication. It’s process-orientated, consistent, and, above all, error .

sheet metal transition calculator

Here is a nice video showing how to unfold a sheet metal part commonly known as flat pattern in Solid Edge. Solid Edge Solid Edge Knowledge Base Filter Feed Refresh this feedUnfolding sheet metal You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design.By unfolding one bend of a sheet metal part at a time, you can produce a flat area or flat blank for further machining operations. This unfold functionality enables you to perform machining operations that are required prior to bending. . Creo . A simple sheet metal workbench for FreeCAD. Contribute to shaise/FreeCAD_SheetMetal development by creating an account on GitHub. . V0.2.63 28 Mar 2023: Fix further unfolding issue by @Syres916. V0.2.62 24 Mar 2023: Add translation support + Portuguese translation by @riqueenz.

By thickening: This mode will simply thicken the unfolding sketch. The imprint curves are also imprinted on one side of the sheet metal part. By unfolding: This mode will unfold the bends, unroll the developable surfaces, and manage the extensions of the unfolding and the forming flanges. The drillings and local deformations are retained.Designing sheet metal parts requires you to think of them and their features as flat, formable objects. Doing that is the key to ensuring manufacturability. . Before unfolding your part in your design program, make small cuts in the corners where two sides meet. They should be at least 0.030 in. wide and locate them at least 0.015 in. (0 .Unfolding Bends. To add an unfold feature: In a sheet metal part, click Unfold on the Sheet Metal toolbar, or click Insert > Sheet Metal > Unfold. In the graphics area, select a face that does not move as a result of the feature for Fixed face. The fixed face can be a planar face or linear edge.

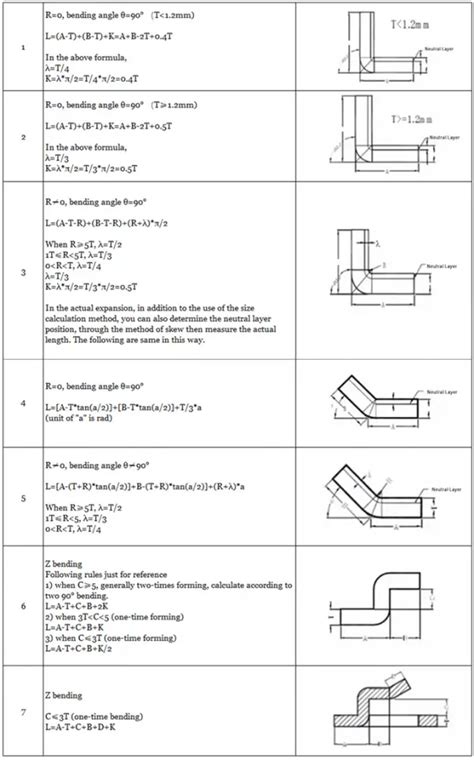

Sheet Metal Unfolding Calculation Guide – How To Unfold Sheet Metal Step By Step. 1. Unfold at right angles. This situation is the simplest, usually we calculate by deducting 1.7 per millimeter of plate thickness, that is: L=A+B-1.7T. (Note: 1.7 is the value for cold-rolled sheet and galvanized sheet. If it is stainless steel sheet, copper .

Sheet Lightning is unfolding software for designing and unwrapping pattern developments for sheet metal designs. It combines an integrated parametric library and a full 3D CAD design environment. The parametric design facility means designs can be created by simply loading a template design and typing in new dimension values.

Sheet Metal Unfold Rule Equations. Register for more free training on this topic at KETIV Virtual Academy. Register Now. Free training, every week, from real experts. 9HUVLRQ 1R 3DJH RI .(7,9 $ &RQWHQWVSimple MS-Excel spreadsheet to calculate a sheet metal cone unfolding. In pressure vessel design, particularly for vessels with conical sections, engineers often use cone unfolding calculations to determine the dimensions of flat patterns that can be cut from sheet metal and formed into the conical shape required for the vessel.You can save your unfolding to a DXF file. The DXF file contains information, such as: bend positions, radiuses, angles of bending, overall dimensions, mater.SHEET METAL UNFOLDING. ACCESS TO SHEET METAL UNFOLDING. If you have already purchased the software for the calculation of sheet metal development, please access this page. Go to Page. Description; Features; Attachments; Ideal for calculating the length of the sheet before bending. Article No. .

With Pintejin automated and highly streamlined sheet metal fabrication service, you can expect a sheet metal fabrication quote within 12 hours and lead times as quickly as three days.Our rapid prototyping offering also includes a solid and reliable manufacturing capability (led by our expert team with 15+ years of experience) and technical and quality assurance, . Hi So that the 2 lateral faces do not stick to the other edge, you modify the radius of folding of 0.1mm (r = 1.1mm), and the unfolding works Edit: I come back to say that for the sheet of 1mm you can put the folding radius = 0.1mm (not zero it is incompatible) so you will have 0.1mm of day between the acceptable edges in sheetMetal workshop,

Unfolding sheet metal You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design. I made the first version of the sheet metal unfolding macro. In order to do so, the code analyses the shape and searches for bends and need to identify all faces of a shape, that belong to a flat piece. The code just is just not prepared to identify counter bores and fails miserably in my macro at this stage. Select a face of a sheet metal component with at least one bend junction. The selected face sets the orientation of the unfolded design. When you select a single face of a sheet metal part, the Unfold button enables.Manufacturing-ready unfolding; Less pre-production work . SPI SheetMetal software extends the sheet metal functionality of the base CAD software with proven features that save time, reduce errors, and optimally link design and fabrication. .

wholesale fabrication metal sheet stamping supplier

Finding a CAD solution specifically for sheet metal products design is a bit tricky because you'll either need a simple 2D CAD system, or ideally: a parametric or direct 3D modeler that allows you to design flanges and work with bend deductions: In short, a CAD-system with a dedicated sheet metal module.

SHEET METAL EXPERTS LOOK HERE!! UNFOLDING V4 IN V5 1. Thread starter Dean0017; Start date Sep 11, 2007; Status Not open for further replies. Sep 11, 2007 #1 Dean0017 Aerospace. Feb 14, 2005 28. Greeting, Situation: I have a curved, CATIA V4, sheet metal type part (.063” thk). I’m using V5 sheet metal design and others. In the process of sheet metal bending, there is a large deviation between the value of sheet metal unfolding calculation by UG software and actual processing. In order to solve this problem, the .

Unfolding sheet metal You can unfold a sheet metal design and changes appear simultaneously in the unfolded component and in the original design.

sheet metal software free download

Dynaform Blanking Solutions: Quick & Easy Sheet-metal Unfold & Analysis Posted on August 24, 2022 September 22, 2022 by Curtis Hsiung, Technical Sales Representative While it is done early in the design process, the process of unfolding a sheet-metal part has considerable implications that can impact later product-cycle stages as well.Shareware Junction periodically updates pricing and software information of LITIO2 - 3D Sheet metal unfolding soft v.2.0.5 full version from the publisher using pad file and submit from users. Software piracy is theft, Using crack, password, serial numbers, registration codes, key generators, cd key, hacks is illegal and prevent future development of LITIO2 - 3D Sheet metal .

free sheet metal layout patterns

With this blog post, we start (or restart?) a series of articles devoted to sheet metal processing. We will cover quite a few things, including sheet metal recognition, unfolding, and treatment of specific features. Like many other geometric modeling applications, this area is not well documented because commercial players do not like to disclose their small dirty secrets.FastAIR® shape development module for sheet metal fabrication. Contact FastCAM for further information. The common feature of all the Shape modules is that very extensive and complex 2D patterns for profile cutting are created from a relatively simple parametric specification of a 2D or 3D assembly (i.e. a Shape) however we presume a working .

free sheet metal bending software

Q1: What are the different types of metal bending? Metal fabricators use various types of metal bending. The most famous types include air bending, rolling, folding, bottoming, coining, and wipe bending. Q2: What is metal bending .

sheet metal unfolding|sheet metal software free download