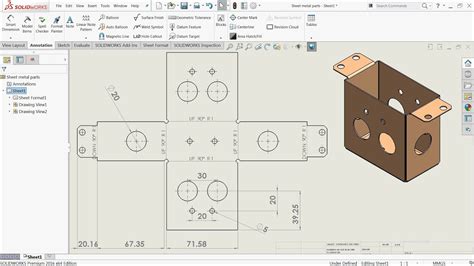

sheet metal drawing process pdf In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post.

Vacuum is one of the most effective methods to hold down parts for CNC cutting or machining. Vacuum systems for CNC routers typically include a vacuum pump, PVC or other specialized .

0 · simple sheet metal drawings

1 · sheet metal forming drawing

2 · sheet metal diagram fabrication

3 · sheet metal deep drawing calculations

4 · sheet metal basic drawing

5 · metal spinning vs deep drawing

6 · metal sheet mechanical drawings

7 · deep drawing in sheet metal

When creating a lighting circuit diagram, it is important to include the junction box and its connections. Start by identifying the power source, typically a breaker panel or switch. From there, trace the circuit to the junction box, noting the incoming and outgoing cables, as well as any connections made within the box.

simple sheet metal drawings

Drawing: Shapes-A myriad of shapes can be formed through multiple draws. Round shapes offer that greatest ease and economy in drawing. Then next best option is square with adequate .

Deep drawing is a metal forming process for creating seamless, sheet metal parts that are closed on one end and have a depth greater than their radius. Deep drawn parts .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .1.3 Metal Forming Processes in Manufacturing ... 2 1.4 Classification of Metal Forming Processes ... 3 Chapter 2 Classification and Description of Sheet Metal Forming Operations .

can i run a cnc machine in my apartment

sheet metal forming drawing

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .

In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post.Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Plate stock > 6 mm thick. Advantage - High strength, good .In sheet metal forming practice, we distinguish five basic modes of deformation: • STRETCHING: The material is expanded in both directions. This mode of deformation is found mostly on . Deep drawing is a sheet-metal forming process for manufacturing a seamless hollow part that is closed at one end and has a height (or depth) greater than its radius. Deep .

In this section we will be considering four foundational DFM considerations in order to create great sheet metal drawings. Manufacturing process mapping; Flat pattern process considerations; Bending specific design considerations; . As .

The deep drawing process in sheet metal fabrication is highly dependent on the precision and quality of die design. As one of the primary determinants of the final product’s quality and dimensional accuracy, the die .Sheet Metal Drawing Operations - It is used to make cup-shaped, box-shaped, or other complex-curved and concave parts. - Figure (3-65) explains this process. . opening, so metal flow through a constricted space gives the drawing process its name. (4) Friction and Compression: it is occurred in the outer edge of blank (flange).Sheet Metal Assembly Drawing Creation. . Automated Drawing Templates Save as pdf, dwg, dxf, . Reduced ECO process by 85 percent Cut number of prototypes by 78 percent. www.egsindia.com 34 Sheet-Metal Customer Reference Creactive designs Chiller Cabinet for .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files . Xometry’s Sheet Metal Tolerance Offerings If a drawing or specification sheet has not been provided by the customer, Xometry will . A .pdf drawing can be attached to the uploaded model if further .ºõ³ . Deep Drawing Process for Sheet Metal. satyendra; August 28, 2023; 7 Comments ; Anisotropy, Blank, Blank holder, Deep drawing, die, drawability, Earing, Expanding, Ironing, Limiting draw ratio, lubrication, Necking, Plastic strain ratio, Punch, Strain hardening exponent, Tearing, Trimming, Wrinkling,; Deep Drawing Process for Sheet Metal. Deep drawing is a .

can older metal brackets hold a ceiling fan

This paper deals with the deep drawing of metal cups using the Marform process. Using this technique, higher limiting drawing ratios can be obtained compared with the conventional deep drawing process. The analytical model of the process is presented initially, followed by the finite element simulations using ABAQUS software. A new friction model based .

Wire drawing Rolling: In this process, the workpiece in the form of slab or plate is compressed between two rotating rolls in the thickness direction, so that the thickness is reduced. . forming of a flat metal sheet into a hollow or concave shape like a cup, is performed by stretching the metal in some regions. A blank-holder is used to .

— Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing process is a shape transforming method.

Deep drawing of sheet metal is one of the most important transformation's process in which a sheet metal blank is drawn into a forming die via a punch force. The conventional deep drawing of sheet metal techniques, known for their wide usage in several industry sectors, are experimental and expensive processes. The sheet metal drawing process typically involves several steps: Design: The design of the final part is created using CAD (Computer-Aided Design) software. Material Selection: The appropriate type and thickness of sheet metal are selected based on the requirements of the final part. Deep Drawing Deep Drawing is a sheet metal forming operation used to make cup-shaped, box-shaped, or other complex-curved, hollow-shaped parts. It is performed by placing a piece of sheet metal over a die cavity and then pushing the sheet into the opening with a punch. The blank is held down flat against the die by a blank holderSHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or objectives of each individual exercise. The exercises are presented in a list format without paragraphs or descriptions.

Sheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they shape and cut the sheet metal into finished parts. Production stamping is generally performed using sheet metal materials .020” to .080” thick, but the process Request PDF | Design and Analysis of a Deep Drawing and Inprocess Electromagnetic Sheet Metal Forming Process | The design as well as the subsequent analysis of a deep drawing and in-process .

Request PDF | On Nov 13, 2024, Bharat Bhushan and others published Numerical Modeling of Incremental Sheet Metal Forming Process for Generating Complex Shapes on Ti6Al4V | Find, read and cite all .— Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. Deep drawing process is a shape transforming method. Request PDF | Thinning and residual stresses of sheet metal in the deep drawing process | a b s t r a c t This paper presents a Finite Element (FE) model developed for the 3-D numerical simulation .

Edited by Taylan Altan and A. Erman Tekkaya ASM International® Materials Park, Ohio 44073-0002 www.asminternational.org Sheet Metal Forming FUNDAMENTALSSheet metal drawings usually contain views both of the fully formed part and of the flat pattern, as in Figure SM.4. You can place views of the part in both states on the same drawing by creating a multi-model drawing. Figure SM.4 COAch for Pro/ENGINEER, Pro/SHEETMETAL, Drawings, .Wire Drawing: Process Mechanics and its characteristics, determination of degree of drawing, drawing force, power, and number of stages-defects in products. UNIT IV Sheet Metal Working – Economical Considerations - Stamping, forming and other cold working processes: Blanking and piercing – Bending and forming – Drawing and its types . SHEET METAL PROCESS - Download as a PDF or view online for free. . If the deep drawing process cannot produce a cup sufficiently deep in one operation, then redrawing operation is used. It may be obtained by any one of the following three methods: Direct redrawing Indirect redrawing Ironing.

PDF | This paper deals with the deep drawing of metal cups using the Marform process. Using this technique, higher limiting drawing ratios can be. | Find, read and cite all the research you need .IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 11, Issue 4 Ver. IV (Jul- Aug. 2014), PP 06-16 www.iosrjournals.org Analysis on Deformation Process in Deep Drawing of Sheet Metal Part by FEM Ramesh Kanttikar1, Bharath S Kodli2, Ravi B Chikmeti3 1 M.Tech. (Student), Mechanical Engineering Department, .

Deep drawing is a sheet metal forming process which is widely used in manufacturing parts for automobile and air craft industries. In this paper, the mechanism of deformation, effect of the .

Request PDF | On Jan 1, 2018, Radha Krishna Lal and others published Study of factors affecting Springback in Sheet Metal Forming and Deep Drawing Process | Find, read and cite all the research .

sheet metal diagram fabrication

I normally use different kind of weapons for different foe, and have crossbow as an extra to shoot boxes. So I really don't have favorites to use since I use most of it. But the ones I tend not to use are daggers and axes.

sheet metal drawing process pdf|simple sheet metal drawings