traditional box beam steel header Box and back-to-back header beams have been commonly used in cold-formed steel framing. The geometry is fabricated using two C-shaped cold-formed steel members. Design practice . Order this sheet metal brake for sale today! Covered by a 1-year parts warranty. Includes lifetime technical support by phone. Questions? Not sure which model you need? Call 1-920-684-4990 with any questions you have about this sheet metal bender for sale.

0 · window and door header framing

1 · metal stud box header detail

2 · metal box header span chart

3 · light gauge steel header chart

4 · insulated headers for 2x6 walls

5 · exterior wall headers

6 · exterior door header detail

7 · boxed header detail

If you're looking for the best CNC machine manufacturers in the USA, you've come to the right place. In this article, we will explore the top 10 CNC machine manufacturers based in the USA, highlighting their expertise, product offerings, and contributions to the industry. 1. Haas Automation Inc.

The Steeler Technical Design Catalog is a collection of typical designs for steel framing and connections to help guide with your design process. The Calalog should only be used as a .

The superior strength and carrying capacity of the HDS means .• Eliminates box beam header assembly. • Reduces material and labor costs up to 50%. • HDS can be screw-attached from either side. • Eliminates stud-to-track nesting for post, header and .

Box Beam Header. Box beam headers use 2 tracks and 2 studs to create a structural box shaped beam. The tracks are horizontal to the ground with the web of the tracks .

Box and back-to-back header beams have been commonly used in cold-formed steel framing. The geometry is fabricated using two C-shaped cold-formed steel members. Design practice .DETAILS. 1 4. www.SCAFCO.comSCAFCO DisclaimerAll data, specifications and detail contained in this publication are intended as a general gu. e for using SCAFCO’s products. .Box headers can be used only in walls supporting just a roof and a ceiling, and in walls supporting a roof, a ceiling, and one center-bearing floor with an interior center-bearing wall. The IRC lists spans for 9-in.-tall and 15-in.-tall box headers.

This video shows metal stud framing box beam header styles. Access the latest in construction video right here: https://goo.gl/wSSry6 Master Construction. B.FRAMECAD have undertaken numerous structural tests to validate the structural performance of bed headers, which show that they perform equally to back-to-back and box beam headers. We also recommend the use of steel L plates . Wood headers are one of the most traditional options. They are often made from solid lumber or laminated veneer lumber (LVL) and are known for their strength and versatility. . Header beam (wood, steel, or engineered) Measuring tape; Level; Saw (if cutting is needed) Hammer or nail gun; Screws (if using steel headers) Safety goggles;

During the session, Roger reviewed the applicable cold-formed steel standards for framing members vs. other cold-formed applications, discussed economical solutions for stud packs, and walked through a design example of a built-up box beam that is not specifically enabled by the current design standards. We are putting a 2" wide rolled steel curved header in a 2x6 wall. Our thinking is that we need to position this header as close to the inside as possible with as much ISO foam to the outside as possible to prevent condensation on the steel. We've decided to use 2-1/2" of ISO which only gets us R16.25 if my math is correct. This allows us to put 3/4" of wood on the .Hand-hewn beams are crafted by hand using traditional tools, resulting in a rough, textured surface with irregularities and tool marks. . that require precisely matching widths and when needing to wrap exposed structural elements such as steel columns and steel I-beams. We can make box beams to match the patina and aesthetic of any of our .header. beams subjected to a combination of bending and web crippling shall be designed using Section C3.5 of the . Specification. For back-to-back . header. beams the equations for I-sections or similar sections shall be used. B2 Box Headers The provisions of this section are limited to box . header. beams as defined in Section A.1.1.1. B2.1 .

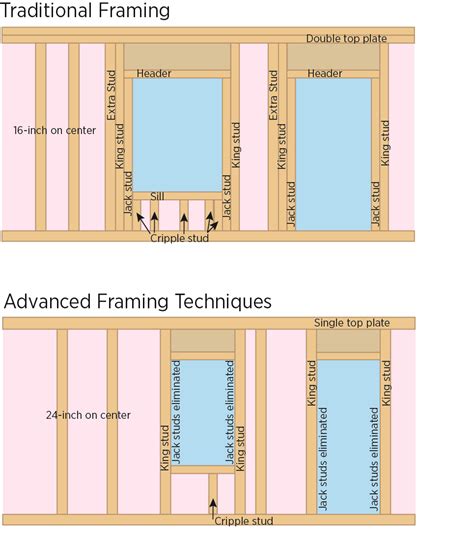

A header in construction is a beam installed over an opening which disperses the load placed on top to the sides. Windows and doors typically have a header on top to support the load above them. Without the header, weight would be placed on the window or door causing damage and/or total failure. In recent years, traditional platform-framing techniques have matured to maximize a structure’s insulation capacity. This is called advanced framing or value-engineered framing, and it came about to enhance a building’s energy efficiency. . Inspectors and framers may not be familiar with box beam headers. And I wonder if all those extra .

window and door header framing

Recessed Door Header (RDH) Load Tables; Recessed Door Header (RDH) Specification Notes; Details & Drawings; . Steel Box Beams; Steel Columns and Posts; Loc Seal Decking; Steel Canopies; All Steel Structures; Solar Frames; . Solar panels or traditional decking; All galvanized framework – no painting required . According to Residential Steel Framing Handbook by Robert Sharff there are several types of header designs such as doubled "C" channels with flanges in or with flanges out and with a header track underneath the "C" channels and a top track attached as the top of the header. Gussset plates and web stiffners may be required, depending on the design.The SHH6 is manufactured in steel thicknesses of 54 mil (16 ga.) and 68 mil (14 ga.) that are intended for use with 6"-deep (min.) box headers, and the SHH3 is manufactured from 68 mil (14 ga.) steel and is intended for 3 5/8" or 4"-deep (max.) box headers and large-flange lay-in .DonoBeam tapered steel box beams can deliver a large unobstructed space economically, with the architectural freedom to incorporate a wide range of aesthetic and practical elements that a project might require. . Traditional I-Beam portal frames tend to buckle rotationally under load and lose their strength. To compensate for this, they .

cnc turnmill machine manufacturers

Advanced construction technologies like the FRAMECAD System hold many advantages over traditional construction techniques. The FRAMECAD design and build methodology is all about the rapid construction of quality buildings, and delivers a faster return on investment and new business opportunities.Steeler is an authorized distributor of the entire Enviro-Beam line. This includes the E-Beam HD (pre-insulated steel header), E-Header Sill, E-King (pre-insulated alternative to the standard dual stud), E-Connection Plate, E-Corner (pre-insulated outside corners), E .

Pre-punched Clip for box header Framing. The Box Header Clip (BHC) is designed to eliminate field cutting metal track into sections. The BHC clip is pre-punched to promote a quick and accurate installation. . AISI S240-20 North American Standard for Cold-Formed Steel Structural Framing (Compliant to ASTM C955, but IBC replaced with AISI S200 .

cnc turning machine manufacturer in bangalore

metal stud box header detail

Our wooden box beams are manufactured to imitate structural wooden beams and designed to cover steel RSJ beams and other unsightly lintels or boxing. We have oak box beams and pine box beams depending on the look you would .ProX Header is a light gauge steel header that provides horizontal and vertical load support. This pre-engineered metal framing component is designed as a 1- or 2-piece steel header that can be used in lieu of 4- or 5-piece built-up (stud .Aug 11, 2024 - The SHH steel header hanger is used to support traditional CFS box headers that are fabricated with top and bottom tracks, as well as large-flange lay-in headers common in curtain-wall construction.

Browse photos of box beam ceilings on Houzz and find the best box beam ceilings pictures & ideas. skip to main content . This is an example of a mid-sized traditional landscaping in Other. Find the right local pro for your project . beaded inset cabinets, white cabinets, marble countertops, white backsplash, stone slab backsplash, stainless .

Box Beams Box beams are built-up beams using dimensioned lumber (2x4 or 2x6) and panels (plywood or OSB) The box is framed with the lumber and the sides are skinned with the panels. The horizontal top and bottom flanges are continuous members as are the vertical ends and internal web stiffeners. The flanges carry the tension andDoes anyone know of good engineering design guides or refrences to analyze the capacity of a built up box beam-column comprised of cold formed steel track and studs? Looking into feasibility of using CFS for a small home project. For context. P, V, M loads are on the order of 1500 lb, 500lb, and 3700 lb-ft. Then we removed just enough of the remaining exterior brick to install the second header. The headers were predrilled with 9/16-inch-diameter holes, so we had to spend some time tweaking and shimming the two sections of steel to align the holes. On some projects the steel is left exposed and flush with the exterior wall.

Trying to figure out what type of header to use. We have very limited vertical space for a header over the doors on the south side and 6" header would be perfect. Would a 6" steel I-beam used as a door way header be sufficient for a 6 foot door way opening (double doors) for a single story house?

Steel Header Hangers - are used to support traditional cold-formed steel box headers, as well as large-flange lay-in headers. SCHA Slide-Clip Connectors - are designed for use in panelized or stick-frame construction to secure cold-formed steel anchors to concrete slabs or steel beams.Our oak box beams are manufactured to imitate solid structural oak beams and designed to cover steel RSJ beams and other unsightly lintels or boxing. Oak RSJ covers are constructed from character grade kiln dried oak sourced from the very best European sawmills. Character grade oak contains small sound and live knots of 30mm diameter maximum.

Steel beams of the same size are considerably heavier, which then require special handling procedures that add to the building cost. Still, using this type of beam is cheaper compared to wood and concrete beams. Like LVL beams, there are PFC steel beams that are pre-made and constructed with a specific design and shape. Thus, you won’t incur . Lot of weight in the steel beam (add 1-2000 pounds to the load in the above paragraph).There are solutions that have some merit. Rebuild the second floor wall as a beam. A few pieces of 2x at the top and bottom, a couple layers of plywood on each side to carry the shear. Expensive but doable (make the beam curved so it deforms tothe proper .garage-door header and to the back wall of the garage. Thus, the design load on the header is: 35 psf x 20 ft ____ = 350 plf 2 2. Find the appropriate beam design. Look in the 18-foot-span column of the load-span tables and find a beam ade-quate to support 350 plf plus the weight of the beam. Such a beam is 24 inches deep and consists of two 2 .

metal box header span chart

CPM offers a variety of sheet metal bending brakes, including straight brakes, leaf brakes, box and pan brakes, hydraulic brakes, autobrakes, and many more. View our inventory to see what suits your sheet metal bending, cutting and fabricating needs.

traditional box beam steel header|window and door header framing