contour sheet metal Contour plaatst functionele en analytische cookies voor het functioneren van de . Ladies can't resist our hand painted perfume bottles, bath sets, Suzani & kilim fashion accessories, and ethnic jewelry boxes. Shopping for a chef? See our Turkish Copper kitchenware, Tea & Spice sets, or Iznik Ceramics.

0 · The Calculation Method of Large Arc Bending In Sheet Metal

1 · Supplier of Sheet Metal Assemblies

2 · Sheet Metal Supplier

3 · Contour Machine Ltd.

4 · Contour Covering Technology: Sheet metal specialist

5 · Contour Classic Series™

6 · Contour

7 · Chapter 6: Sheet Metal Setting the Parameters of the Sheet

8 · C1

9 · C

voltage monitoring, 8 port, m12 eurofast field connectors, junction box, devicenet, (u0205), 300v, 7/8" minifast bus in/out

Contour Covering Technology BV is a supplier of sheet metal components and assemblies. We distinguish ourselves by our clean and accurate production processes. We use our broad .Contour is a specialist in sheet metal precision bending. Together with our .Contour is designed as a repeat factory for small to medium sized series. The best .Examples of the Sheet Metal components and (incl. weld and cleanroom) .

The Calculation Method of Large Arc Bending In Sheet Metal

Supplier of Sheet Metal Assemblies

Contour plaatst functionele en analytische cookies voor het functioneren van de .Address Industrieweg 32 NL-7102DZ Winterswijk The Netherlands. T: +31 .Contour is specialized in the production of sheet metal welding assemblies. All .

At Contour we always use the right packaging, keeping products free from .

During assembly, all individual components come together just in time. At Contour .Our clean room conforms to the ISO14644-1 class 5 standard. The clean room is set .Lead is an important material. If applied correctly, it contains x-rays within the .

how to build a house inside a metal building

Sheet Metal Supplier

how to blow up metal boxes in unturned

Contour is a specialist in sheet metal precision bending. Together with our customers, we optimize complex designs for production. A highly reproducible design is the result.During assembly, all individual components come together just in time. At Contour we work with a complete digital system in order to accomplish this. The .Contour Classic Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not .Contour Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.

Contour excels in laser cutting, bending, welding, and assembly of custom sheet metal. The range of sheet metal production processes is exceptionally broad; pickling and passivation, powder .

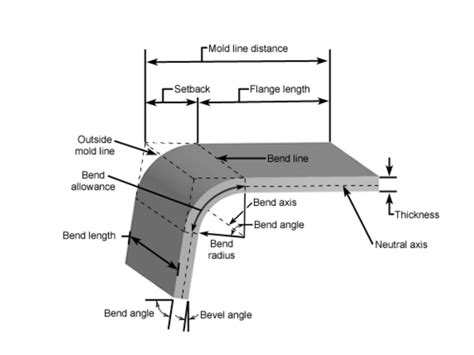

Contour Machine Ltd. established a reputation for the fabrication of high-quality equipment, providing excellent service, and offering an extensive line of custom metal sheet fabrication.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal . For sheet metal bending large arcs, when the fillet R divided by the sheet metal thickness is equal to 6.5 times, the neutral layer is at the center of the sheet metal thickness. .

Contour Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.Contour Covering Technology BV is a supplier of sheet metal components and assemblies. We distinguish ourselves by our clean and accurate production processes. We use our broad portfolio of competences to supply sheet metal components to a diversified mix of market sectors.Contour is a specialist in sheet metal precision bending. Together with our customers, we optimize complex designs for production. A highly reproducible design is the result.

Contour Machine Ltd.

During assembly, all individual components come together just in time. At Contour we work with a complete digital system in order to accomplish this. The progress of each individual production order is kept track of in real-time, using wireless tablets and mobile barcode scanners.

Contour Classic Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.

Contour Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.

Contour excels in laser cutting, bending, welding, and assembly of custom sheet metal. The range of sheet metal production processes is exceptionally broad; pickling and passivation, powder coating, and assembly in a clean room are also part of the service package.Contour Machine Ltd. established a reputation for the fabrication of high-quality equipment, providing excellent service, and offering an extensive line of custom metal sheet fabrication.To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2.

For sheet metal bending large arcs, when the fillet R divided by the sheet metal thickness is equal to 6.5 times, the neutral layer is at the center of the sheet metal thickness. . Whether it’s a gentle curve for architectural elements or a complex contour for aerospace components, craftsmen tailor their approach to meet the unique .Contour Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.

Contour Covering Technology BV is a supplier of sheet metal components and assemblies. We distinguish ourselves by our clean and accurate production processes. We use our broad portfolio of competences to supply sheet metal components to a diversified mix of market sectors.

how to bend sheet metal without a bender

Contour is a specialist in sheet metal precision bending. Together with our customers, we optimize complex designs for production. A highly reproducible design is the result.During assembly, all individual components come together just in time. At Contour we work with a complete digital system in order to accomplish this. The progress of each individual production order is kept track of in real-time, using wireless tablets and mobile barcode scanners.

Contour Classic Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.

Contour Series™ gives you the custom look you want within your budget. If one of our standard profiles does not match your design requirements, no problem, TMP will fabricate the profile that matches your project needs – not ours.Contour excels in laser cutting, bending, welding, and assembly of custom sheet metal. The range of sheet metal production processes is exceptionally broad; pickling and passivation, powder coating, and assembly in a clean room are also part of the service package.Contour Machine Ltd. established a reputation for the fabrication of high-quality equipment, providing excellent service, and offering an extensive line of custom metal sheet fabrication.

To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet metal part such as sheet metal rule, thickness, material, and unfold rule. You can change these preferences as per your requirement. 2. For sheet metal bending large arcs, when the fillet R divided by the sheet metal thickness is equal to 6.5 times, the neutral layer is at the center of the sheet metal thickness. . Whether it’s a gentle curve for architectural elements or a complex contour for aerospace components, craftsmen tailor their approach to meet the unique .

Twin City Sheet Metal is a custom sheet metal and steel fabrication shop serving the State of Maine. With over 75 years of experience, we bring you superior craftmanship and rapid turnaround times while taking pride in our ability to tackle any project, large or small.

contour sheet metal|Contour Machine Ltd.