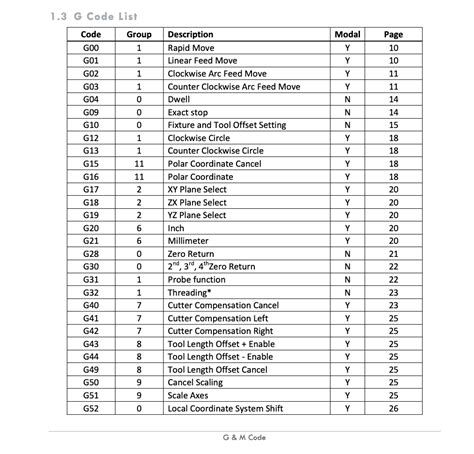

cnc machine language g code list G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow. Having incorporated that glass-half-full mindset, let’s identify some common sheet metal defects. Sheet Metal Splits A series of wrinkles is growing and propagating. The layers of metal are .

0 · list of fanuc g codes

1 · list of all g codes

2 · g code table listing

3 · g code reference chart

4 · g code for cnc milling

5 · complete g code list

6 · cnc turning g code list

7 · cnc milling g codes list

Lancing is a partial cutting operation where bending and piercing is done using the same punch. In case of a rectangular profile, we can say that cutting 3 sides and bending the remaining would result in lancing. Please note .

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

CNC G-codes & M Codes for milling and turning with explanations, .

cnc machine lobrecad

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow. CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a. Mazak G code list for cnc machinists . G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using .Multi-chapter guide to G-Code describing: what is G-Code for CNC machining, G Code commands, G Code Reference List, G Code examples, G code vs M Code, and more.

List of common CNC G codes and their meanings.

list of fanuc g codes

A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or . G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands.

G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

G-codes, which control tool movement and cutting operations, form the backbone of CNC programming. Key G-codes include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), and G81-G89 (canned cycles for drilling, boring, and tapping).

G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a. Mazak G code list for cnc machinists who work on MAZAK machining centers.

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining.

Multi-chapter guide to G-Code describing: what is G-Code for CNC machining, G Code commands, G Code Reference List, G Code examples, G code vs M Code, and more. List of common CNC G codes and their meanings. A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or presets the control system to use a certain mode or operation. Below is the list of G-codes that are used in most modern CNC Milling machines:

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool motion, while M Code manages machine operations like spindle activation and coolant flow.

cnc machine lagrange il

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) G-codes, which control tool movement and cutting operations, form the backbone of CNC programming. Key G-codes include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), and G81-G89 (canned cycles for drilling, boring, and tapping). G-code is a programming language used by CNC machines to execute specific tasks. It stands for “Geometric Code” and guides the machine on where to move, the speed of movement, and the path to follow.CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for Fanuc cnc control which are necessary for a. Mazak G code list for cnc machinists who work on MAZAK machining centers.

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining.Multi-chapter guide to G-Code describing: what is G-Code for CNC machining, G Code commands, G Code Reference List, G Code examples, G code vs M Code, and more.

list of all g codes

g code table listing

List of common CNC G codes and their meanings.

cnc machine kit australia

g code reference chart

Laser welding technology for sheet metal does exactly that, revolutionizing industries from automotive to high-tech electronics. This article explores the advantages of laser welding over traditional methods, detailing its superior heat control, speed, and flexibility.

cnc machine language g code list|cnc turning g code list