stretching sheet metal process Sheet metal stretching is a process used to shape metal components by subjecting the metal sheet to forces that cause it to elongate and change shape. What factors affect the sheet metal stretching process? Metallic fabrics can use the metal to different degrees. Some fabrics have a light embellishment, others a medium level, and others can have the metal densely applied. Golden Galaxy uses a fabric with a complete metallic coverage—gorgeous with that blue!

0 · stretch forming

1 · perforated steel stretched metal sheet

2 · perforated steel sheet home depot

3 · perforated sheet metal lowe's

4 · perforated metal strips screwfix

5 · metal sheets at screwfix

6 · metal grating sheets near me

7 · expanded metal sheet near me

A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete. They are standard .

stretch forming

Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads prevent metal flow inward from the flange area. In contrast with drawing, significant metal thinning occurs in stretching, especially in the biaxial . Sheet metal stretching is a process used to shape metal components by subjecting the metal sheet to forces that cause it to elongate and change shape. What factors affect the sheet metal stretching process?Stretch forming: Forming force. F = (Y + UTS)/2 * A. S. F = stretch forming force (lbs) YS = material yield strength (psi) UTS = ultimate tensile strength of the material (psi) A = Cross .

Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: .Calculate the force required to stretch form a wing span from a sheet of 2219 aluminum having a cross-sectional area of 13x305 mm, a yield strength of 250 MPa and a UTS of 360 Mpa.

cnc precision machining aluminum parts pricelist

Stretch forming of a sheet metal is a forming process that involves stretching a metal sheet over a die to produce complex and contoured shapes. It is commonly used in the .SHEET STRETCH FORMING Sheet Stretch Forming is a fast, economical, and accurate way to form a large panel from a metal sheet. The process involves stretching the sheet to a calculated yield point and forming it over a tool. Transverse Sheet Stretch Forming Press (FET/T) Up to 12 independently controlled axes allow for

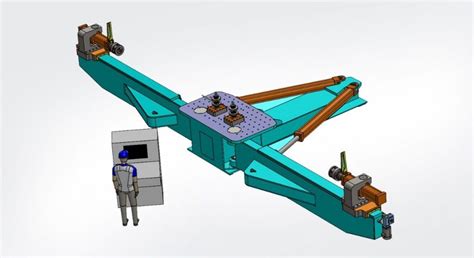

“Multi-point stretch forming (MPSF)” concept is derived from MPF (Zhou et al., 2005), a MPSF tooling has been developed and used to stretch form aircraft outer skin parts as shown in Fig. 1.The purpose of this paper is to investigate and understand the basic physical phenomena in the multi-point stretch forming of sheet metal, including the influence of the . The key is to try to form the sheet metal with as little stretching as possible, although a slight amount of stretching will occur because tension is involved in the drawing process. . Stretching. In the stretching process, the .The answer lies in the meticulous sheet metal fabrication process. Ever wondered what goes into shaping the metal components we use daily? The answer lies in the meticulous sheet metal fabrication process. . This involves anchoring the metal sheet’s edges and stretching it over a form or die to achieve the final shape. Step #5: Joining the .

The stretch press grips the piece of sheet metal securely along its edges using gripping jaws which are attached to a carriage that’s pulled by pneumatic or hydraulic force, stretching the sheet. The tooling used in this process is a solid, contoured stretch form block, called a form die. https://www.proshaper.com Our Amazon Storefront:https://www.amazon.com/shop/proshaper Wray wanted to show how to stretch and shrink aluminum in an extreme wa. Later, Li et al. 23 proposed a forming process of multi-gripper flexible stretch forming (MGFSF), in which Pascal’s law of multi-cylinder hydraulic system, strain hardening, and minimal resistance force of the material are employed. 24,25 Wrinkling or the problem of conformability of sheet metal to the desired shape is prone to occur when .Please find below the answer for Metalworking process that stretches sheet metal. CodyCross is one of the most popular games which is available for both iOS and Android. This crossword clue belongs to CodyCross Performing Arts Group 889 Puzzle 5. The answer we have below for Metalworking process that stretches sheet metal has a total of 7 letters.

Step 1: Place the warped sheet on the platform and hold the sheet metal with your left hand and the hammer with your right hand. Step 2: Begin tapping along the unwarped diagonal line, and then extend to both sides in order to .

In the process of shrinking and stretching sheet metal, the nibbler works with a variety of separate parts to achieve the desired effects that the experienced operator wants to have while stretching sheet metal. The nibbler works with a planishing hammer and 2 sets of tools, one for shrinking a metal part and the other for stretching metal. Sheet stretch forming machines are designed to meet all tonnage, length, and width specifications, Goodwin adds. Historically, these machines have been used in stretch forming aluminum fuselage, wing, and engine cowl panels. . a lower-cost metal at its base and a very high-cost metal at its skin. The process then compacts the two layers of . Thus, stretch bending process of sheet metal is type of sheet metal operation. In this research, the stretch bending limit ratio for ASTM1020, ASTM B209 and AA3004 sheets have been determined . The jaw is used to stretch the material after which the table rotates wrapping the taunt material onto the die. This equipment also has a wiper that is tasked with pressing a shoe with an identical profile against the desired section. Step-by-step Stretch Forming Process in Sheet Metal. Stretch Forming Metals

The process of stretching sheet metal has been described as working with pizza dough. However, those who have studied and mastered this art may raise an eyebrow at this simplistic explanation. . The benefits of stretch forming sheet metal. Stretch forming offers superior surface quality and shape control. The process also allows for the .Sheet metal forming processes are useful in manufacturing components in automotive, aerospace, defense and stamping industries. . tensile instability in stretching continuous sheet. Week 6: Sheet formability. Lecture 12 : Forming limit curve . and ‘Metal Forming Technology and Process Modeling’ published by McGraw Hill Education, India. .tool is moving on a spiral path and stretching the sheet metal inward. The thickness of sheet metal is reduced [M. Pohlak, 2007]. This process produced asymmetric shapes, hence the process is known as Asymmetry incremental forming (ASIF) [J. Jesweit et. al, 2005]. The comparison between spinning and ISF is shown in Table 1.

the sheet metal stretch flanging process in the area of its finite element analysis. Figure-1. Different types of flanges (Semiatin S.L., 2006). 2. OVERVIEW OF STRETCH FLANGING PROCESS Stretch flanging process is one of the common sheet metal forming operations. On the basis of product obtained after flanging operation, stretch flanging can be STRETCH FORMING OPERATIONS Stretching is the process of stressing the work blank beyond its elastic limit by moving a form block towards the blank or sheet metal. The form block has projections of exact size required on the blank which is in the form of depressions on the same blank. Stretching is mainly done for straightening a part to obtain .

perforated steel stretched metal sheet

perforated steel sheet home depot

SHEET METAL PROCESS - Download as a PDF or view online for free. . It is the capability of the sheet metal to stretch without necking and failure. 11. SHEARING PROCESS Shearing is a metal fabricating process used to cut straight lines on flat metal stock. During the shearing process, an upper blade and a lower blade are forced past each other .

Forming speed influences the amount of stretch and flow that occurs in a drawn or stretched part. Think of your metal as putty: Pull it too fast and it breaks, but pull it slow and it stretches. When subjected to deep drawing, metal behaves in a similar fashion. Metal needs time to flow into the die.This is a process that cuts sheet metal by applying shear stress along a straight line. The sheet metal is placed between two blades, one fixed and one moving, that create a shearing force to separate the metal. . Stretch forming: This process involves stretching the sheet over a curved surface, using a clamp and a form block. The clamp holds . The computational results for adaptive simulation of sheet stretching and drawing process having different radius ratios (sheet radius to punch radius) are shown in Table 3.The table depicts initial mesh, number of meshing required to get the 7% accuracy, elements in refined mesh and total CPU time required for 20 mm punch displacement.The adaptive mesh plots at .• typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodies . kitchen utensils • sheet metal is formed by rolling; if the metal is thin, it is generally coiled • shearing, bending, stretching are the most common processes for working with sheetmetal to create .

Stretching the metal profile. The process of extending the metal sheet in a certain direction is referred to as stretching. This process strengthens the sheet metal by orienting the metal’s grain in a certain direction. Adding Ribs, Beaded and Punched Holes, Adding Straight Bend, Flange, or Hems, Adding Triangular Ribs to Bending Place .conditions with a die during stretching, sequential sheet metal stretching and bending by arms of a special machine and bi-curvature of the formed parts. Consequently, it has been decided to use numerical simu-lation of the forming process in order to predict the effects of die shape, material and process parameters on the final part shape.

Three Main Tools Used to Stretch Sheet Metal For various applications, sheet metal needs to be stretched into shape. To do this effectively and efficiently, three main types of tools are used: 1. Planishing Hammers These hammers are used to form metal as well as to smooth metal after it is formed. Metal is placed on a hard surface and lightly . Stretch-forming based on loading at discrete points (SF-LDP) is a new stretch-forming process, by controlling the loading trajectory at each discrete point; the process can fulfill the sheet metal deformation along the prescribed forming path. In this paper, force-controlled SF-LDP process was proposed and discussed. The sheet metal deformations in SF-LDP were .

cnc precision machine el paso tx

Pull boxes are used along with conduit to simplify wiring installation, hence their name. They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive .

stretching sheet metal process|perforated sheet metal lowe's