anti foam for cnc machining Foaming in CNC coolant systems can significantly hinder machining . Shop Wayfair for the best adjustable vanity light electric junction box. Enjoy Free Shipping on most stuff, even big stuff.

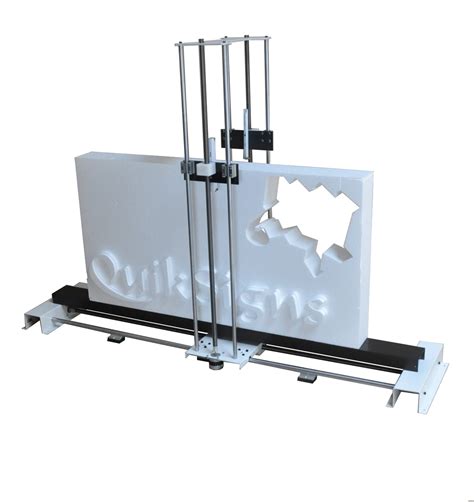

0 · hobby cnc foam cutter

1 · high density foam cnc

2 · cnc router for foam cutting

3 · cnc machine for foam cutting

4 · cnc machine for eva foam

5 · cnc foam router for sale

6 · cnc foam machining services

7 · best router bit for foam

Choose from the huge collection. Lunch Box for office|tiffin container|steel tiffin box for kids|steel dabba set for kitchen|storage box with lids|tiffin condos|steel tiffin boxes|safe lunch box|Steel .

Foaming in CNC machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the machinery. Understanding the causes of foaming and implementing effective solutions can help maintain a .

Foaming in CNC coolant systems can significantly hinder machining .

Continuous monitoring and maintenance are crucial for preventing coolant .Choosing the right coolant is essential for maintaining the efficiency and . Foaming in CNC coolant systems can significantly hinder machining performance and efficiency. By using anti-foaming additives specifically designed for CNC coolants, you can . Continuous monitoring and maintenance are crucial for preventing coolant foaming in CNC machining operations. Foam can significantly reduce the effectiveness of the coolant, .

hobby cnc foam cutter

What you can do is to try to eliminate the things that excite the coolant and add unwanted air to the coolant. Limiting coolant flow and pressure to what is needed is a good .

With most coolants that I've worked with you can go about as low as 5 without any problems. Also, you should be able to get some anti-foam from you chemical supplier, seem . Ever dealt with annoying coolant foam? Let's talk about how water hardness plays into it, and learn about how to tackle this issue and keep your machining foam-free.

Coolant foaming during metalcutting can be a messy headache. But with a little detective work, this bubbly problem may be understood and controlled. Foaming in CNC machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the machinery. Understanding the causes of foaming and implementing effective solutions can help maintain a smooth and efficient machining process.

high density foam cnc

Foaming in CNC coolant systems can significantly hinder machining performance and efficiency. By using anti-foaming additives specifically designed for CNC coolants, you can effectively break down foam and prevent its formation.

Continuous monitoring and maintenance are crucial for preventing coolant foaming in CNC machining operations. Foam can significantly reduce the effectiveness of the coolant, leading to overheating, increased tool wear, and compromised machining quality. What you can do is to try to eliminate the things that excite the coolant and add unwanted air to the coolant. Limiting coolant flow and pressure to what is needed is a good place to start. The cabinet washdown-flood system is also another place to look. Often, the washdown is not needed on a continuous basis. With most coolants that I've worked with you can go about as low as 5 without any problems. Also, you should be able to get some anti-foam from you chemical supplier, seem as though all coolant manufacturers make an anti-foam for their product. Ever dealt with annoying coolant foam? Let's talk about how water hardness plays into it, and learn about how to tackle this issue and keep your machining foam-free.

cnc router for foam cutting

Coolant foaming during metalcutting can be a messy headache. But with a little detective work, this bubbly problem may be understood and controlled. If you aren't using high pressure coolant pumps and you are getting foaming, you should be getting free support (and defoamer) from your coolant supplier. And, and explanation of why their product is failing. First, let's back up. The No.1 common cause of foaming is HP applications with coolants not intended to be used for HP.

Shop quality Coolant Additives Treatments Test Strips at MSC Direct today! Our premium selection features lasting durability and top performance. Choosing the right coolant is essential for maintaining the efficiency and performance of your CNC machining operations. By consulting with your coolant supplier and selecting a coolant with anti-foaming properties, you can prevent foaming, enhance lubrication, and improve machining performance.

Foaming in CNC machining coolant systems is a common issue that can lead to decreased efficiency, poor surface finishes, and even potential damage to the machinery. Understanding the causes of foaming and implementing effective solutions can help maintain a smooth and efficient machining process.

Foaming in CNC coolant systems can significantly hinder machining performance and efficiency. By using anti-foaming additives specifically designed for CNC coolants, you can effectively break down foam and prevent its formation. Continuous monitoring and maintenance are crucial for preventing coolant foaming in CNC machining operations. Foam can significantly reduce the effectiveness of the coolant, leading to overheating, increased tool wear, and compromised machining quality. What you can do is to try to eliminate the things that excite the coolant and add unwanted air to the coolant. Limiting coolant flow and pressure to what is needed is a good place to start. The cabinet washdown-flood system is also another place to look. Often, the washdown is not needed on a continuous basis. With most coolants that I've worked with you can go about as low as 5 without any problems. Also, you should be able to get some anti-foam from you chemical supplier, seem as though all coolant manufacturers make an anti-foam for their product.

Ever dealt with annoying coolant foam? Let's talk about how water hardness plays into it, and learn about how to tackle this issue and keep your machining foam-free. Coolant foaming during metalcutting can be a messy headache. But with a little detective work, this bubbly problem may be understood and controlled. If you aren't using high pressure coolant pumps and you are getting foaming, you should be getting free support (and defoamer) from your coolant supplier. And, and explanation of why their product is failing. First, let's back up. The No.1 common cause of foaming is HP applications with coolants not intended to be used for HP.Shop quality Coolant Additives Treatments Test Strips at MSC Direct today! Our premium selection features lasting durability and top performance.

cnc machine for foam cutting

cnc machine for eva foam

cnc foam router for sale

Shop Valve Boxes online at AceHardware.com and get Free Store Pickup at your neighborhood Ace.

anti foam for cnc machining|cnc foam machining services