cnc subtractive manufacturing A decades-old technique, subtractive manufacturing (computer numerical control, or CNC machining) is a tried-and-true manufacturing .

cnc turning parts processing price list,SLD Precision specializes in delivering high-quality CNC turning parts for various industries. With state-of-the-art technology and a commitment to excellence, trust us for precise and reliable manufacturing solutions.

0 · subtractive manufacturing methods

1 · subtractive manufacturing definition

2 · cnc machining industry

3 · additive vs subtractive

4 · additive manufacturing vs subtraction manufacturing

CNCPros.com offers a wide variety of parts designed to fit your Fadal like Ballscrews, ATC clips, spindles, resolvers, amplifiers, inverters and more – all on-the-shelf, ready-to-ship today! Lowest prices on the things you really need.

Explore the key differences, advantages, and applications of additive manufacturing and subtractive manufacturing. Discover when and how to use each method in various industries.

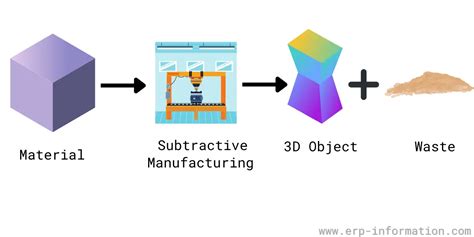

A decades-old technique, subtractive manufacturing (computer numerical control, or CNC machining) is a tried-and-true manufacturing . CNC machining is a "subtractive" manufacturing process that typically uses computerized controls and machine tools to remove layers of material from a blank (or workpiece) and produce a custom part.CNC machining is the most common subtractive manufacturing technology today and a hugely flexible and robust way to produce custom metal and plastic parts. Using CAD models, CNC machines precisely remove material from a solid . Key Takeaways. CNC vs 3D printing: CNC is a subtractive manufacturing method that removes material from a larger block, while 3D printing is an additive manufacturing method that builds material layer by layer.

Additive Manufacturing vs. CNC Subtractive Manufacturing. Manufacturing in the modern age is overshadowed by an ongoing debate between two distinct but interwoven forces - CNC Subtractive Manufacturing (CSM) and Additive .

Subtractive manufacturing is an umbrella term for various controlled machining and material removal processes that start with solid blocks, bars, rods of plastic, metal, or other materials that are shaped by removing material through . A: CNC turning encompasses the removal of material from the surface of the workpiece to form the final component; hence, it is classified as a subtractive type of . Computer Numerical Control (CNC) machines revolutionized the industry and remain central to the subtractive manufacturing process today. Whatever form of machining you’re talking about, CNC approaches bring us .

CNC machining is a "subtractive" manufacturing process that typically uses computerized controls and machine tools to remove layers of material from a blank (or workpiece) and produce a custom part. This method is often .

CNC machining is a prominent subtractive manufacturing technique. The devices are equipped with various cutting tools for specific machining operations. Which is More Eco-friendly: Subtractive vs Additive .CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is . Companies can either buy additive manufacturing equipment to add to their CNC machines, or they can buy new machines that have both additive and subtractive capabilities. The Future of Subtractive Manufacturing A range of new technologies could transform the subtractive manufacturing technique landscape over the next 10 years. The addition of a wire-fed metal 3D printing head allows a widely used standard machining center to become an additive/subtractive hybrid machine. . CNC Machining External Inspection (CMM, gaging, etc.) Internal Inspection (CT scan, X-ray, etc.) . Additive Manufacturing is the media brand devoted to industrial applications of 3D printing .

Subtractive methods like CNC machining still hold a solid place in manufacturing for good reason. It's just that now, with AM in the mix, engineers have more options at their disposal. Why Additive Manufacturing Is Gaining Popularity. Additive manufacturing has been making waves in industries ranging from aerospace to medical devices.Additive vs. Subtractive CNC Machining. CNC machining includes both additive and subtractive processes, each with distinct methodologies: Subtractive Machining: Involves removing material from a solid block to create a part. Common processes include milling, turning, and drilling. This method is highly efficient for producing precise components .The choice between CNC subtractive manufacturing and additive 3D printing ultimately depends on the specific requirements of the project. For high-precision, high-strength parts with simpler geometries and high production volumes, CNC machining is often more cost-effective despite its higher setup and material costs. Conversely, for low-volume .

weatherproof electrical box suppliers

Enhancing undergraduate understanding of subtractive manufacturability through virtualized simulation of CNC machining. Roby Lynn, Kathryn W. Jablokow, Christopher Saldana, Thomas Marshall Tucker, Thomas Kurfess. Engineering Division (Great Valley)SUBTRACTIVE MANUFACTURING : CNC MACHINING. Linkedin Envelope. Our state-of-the-art CNC machines are designed to deliver exceptional results for your manufacturing needs. With unmatched accuracy and efficiency, our machines can transform raw materials into intricate and high-quality parts.Hoosier Pattern provides additive & subtractive manufacturing, 3D Rapid prototyping, CNC machining and more in Decatur, IN. Skip to content (260) 724-9430. Send a File. About. Meet the Team; Employee Spotlight; Our Facility; Trade Shows; . Subtractive & .On the other hand, subtractive manufacturing uses CNC machines to cut materials, achieving high accuracy and smooth finishes, especially for large-scale production. By mixing these two methods, we provide efficient and affordable production with high precision. With ISO 9001:2015 certification, we promise reliable quality and fast delivery .

Subtractive manufacturing is an umbrella term for different kinds of controlled machining and material removal processes. These are either performed manually or more commonly, driven by computer numerical control (CNC). Subtractive methods can start with solid blocks or material forms made from metals, plastics, wood, or other materials that . Additive manufacturing, better known as 3D Printing, first started in the 1980s. Back then, it was a novelty concept reserved for advanced engineering research laboratories. In the 1990s, 3D printing made waves in the medical arena thanks to its ability to create custom medical devices. By the early 2000s, the open-source movement brought 3D printing Subtractive Manufacturing: Subtractive manufacturing is better for large-volume batches. Multi-axis CNC machining can produce parts at a very high speed. Manufacturing Speed. A higher manufacturing speed means a lower .

Hybrid CNC machines represent a groundbreaking integration of additive manufacturing (3D printing) and subtractive machining (CNC milling). These advanced systems combine the precision of traditional CNC technology . Subtractive manufacturing can be performed manually by a machinist. More commonly it’s a highly complex process used by a CNC machine. It is a decades-old practice with a demonstrated history of effectiveness in the . The Precision of Subtractive Manufacturing: Exploring CNC Machining. Transitioning from the innovative layers of additive manufacturing, let's focus on the precision and reliability of subtractive manufacturing, particularly CNC machining. As the name implies, subtractive manufacturing involves removing material to create parts, a stark .

One typical example of subtractive manufacturing is CNC machining. It uses computer-controlled machines to remove material from a workpiece. A virtual model created in CAD software is used as an input to the fabrication equipment in CNC machining. The user’s commands, combined with the program simulation, start tool paths that enable the .At Zero3D, we are experts in subtractive manufacturing (CNC machining), a robust way to create high-quality and durable custom solutions. CNC (Computer Numerical Control) machining involves subtracting material from a piece of hard or soft .Additive Manufacturing. In contrast to the subtractive process of removing material from a larger piece, additive manufacturing or 3D printing processes build objects by adding material one layer at a time, with each successive layer bonding to the preceding layer until the part is complete.. Just like subtractive CNC tools, additive manufacturing technologies create parts from CAD .Subtractive Manufacturing is a full-service Computer Numerical Control (CNC) Machine Shop servicing the San Francisco Bay Area, Central Coast and Central Valley Regions.

After all, subtractive manufacturing is really CNC machining—a process that removes material from a larger piece of material through standard machining processes such as milling, turning/lathing or drilling until the prototype part is created. Subtractive manufacturing gives you the opportunity to design, prototype, and manufacture in end-use .Additive Manufacturing. In contrast to the subtractive process of removing material from a larger piece, additive manufacturing or 3D printing processes build objects by adding material one layer at a time, with each successive layer bonding to the preceding layer until the part is complete.. Just like subtractive CNC tools, additive manufacturing technologies create parts from CAD . The subtractive manufacturing machine we use as our test bed is the Pocket NC V2-10, which is illustrated in Fig. 1. . This work contributes to the advancement of DTs in CNC manufacturing processes through the design and development of an extended DTE on a LinuxCNC-controlled subtractive manufacturing machine. The extended DTE has two .

Subtractive manufacturing, like CNC machining, removes material from a solid block. When paired with additive methods, it decreases waste despite usually generating more of it. This mixed method improves material utilization, increasing effectiveness. By employing both approaches strategically, manufacturers can reduce waste, decrease expenses . 2.2 Subtractive Manufacturing- CNC-RP. CNC-RP uses a 4-axis CNC machine confi guration to machine parts directly from bar stock. Based on the . selection of machini ng parameters such as MRR .

subtractive manufacturing methods

Jiangnan CNC Machine Tool Co., Ltd. is situated in the beautiful coastal city of Wenzhou. Established in 2006 with a registered capital of 50 million RMB, our company integrates .

cnc subtractive manufacturing|additive vs subtractive