cnc machine tools code list Jun 26, 2024 $49.95

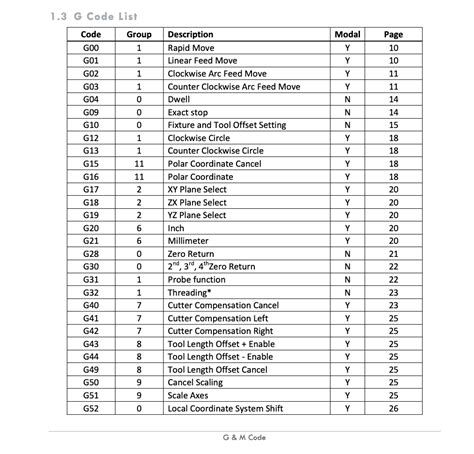

0 · list of all g codes

1 · g code table listing

2 · complete g code list

3 · cnc turning g codes list

4 · cnc milling g codes list

5 · cnc machine codes list pdf

6 · cnc machine code example

7 · cnc g code list download

$94.99

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections .

CNC G-codes & M Codes for milling and turning with explanations, .

G-codes and M-codes serve distinct yet complementary roles in CNC programming. G-codes focus on controlling the geometry and movement of the CNC machine, . Jun 26, 2024 CNC programming is essential for transforming ideas into tangible parts with precision. G Code and M Code are fundamental languages, dictating every movement and function of a CNC machine. G Code controls tool .

G-codes, which control tool movement and cutting operations, form the backbone of CNC programming. Key G-codes include G00 (rapid positioning), G01 (linear interpolation), G02/G03 (circular interpolation), and G81-G89 .

G and M codes are the basic programming languages for CNC machines. The codes automate the processes by giving the CNC machine a standardized set of step-by-step instructions to follow without human intervention. This allows precise and repeatable cutting of complex 3D parts. G codes control the machine's movements.

10. 5-Axis CNC Machines. 5-axis CNC machines allow a cutting tool to move in five different directions — X, Y, Z-axes, and A and B, which the tool rotates around. Programmers can approach a workpiece from all . CNC machine tools: These are devices or tools that enhance the performance, convenience, and safety of your CNC machine.They can help you with measuring, cutting, engraving, sanding, and more. Types of tools: There .

Osai 10 Series CNC M Codes complete list for cnc machinists programmers who work on cnc machines with Osai 10 Series cnc control. Osai 10 Series CNC M Codes M. G Code for CNC Dummies Otherwise, the machine tool will move according to the assigned offset values. (2) Before executing the G53 command, manually or using the G28 command, return the machine tool to the origin. This is because the machine tool coordinate system must be set before issuing the G53 command. G54 : Selection of workpiece coordinate system 1THE LIMITLESS POSSIBILITIES OF A FLEXCNC MACHINING CENTER The FlexCNC is more than a standard machining center. With features that help businesses increase throughput and profit, it outperforms the competition with next-level productivity. FlexCNC machines are purpose-built for accuracy and efficiency. Our vertical machining centers are uniquely capable of .Makino Professional 3 CNC Control (Makino Pro 3) G Code list for cnc machinists who work on CNC machines with Makino Pro 3 (Fanuc 16i/18i ) CNC controls. M

list of all g codes

what is cnc vmc g code m code, g code list, m code list, m code of cnc machine, g code m code for vmc cnc, g-m code fanuc, difference, what is m code . Home; Quality Management; CNC-VMC Pro; Engineering; ITI; . G49 - Tool length compensation cancel. G53- Machine constant zero. G54 - Work coordinate system 1 select. G55 - Work coordinate .

g code table listing

The webpage provides a comprehensive guide on M-Codes for Haas Automation Inc. mills.Anilam G Code List for CNC machinists who work on CNC lathe machines with Anilam CNC controls like 4200T More than one G-code may be specified per block. If a. Home We share CNC machine G-code tutorial and list of important G-code for CNC programming. [email protected] +86 769 8289 0830; Design. Calculator. Turning Speed And Feed Calculator . For a CNC machine tool, to make it move and complete the processing of a part, programming is an essential step. For a part of the processing quality, depends on .Tool nose radius compensation cancel: G41: Tool nose radius compensation left: G42: Tool nose radius compensation right: G70: Finish machining cycle: G71: Turning cycle: G72: Facing cycle: G73: Pattern repeating cycle: G74: Peck drilling cycle: G75: Grooving cycle: G76: Threading cycle: G92: . Complete list of cnc machine G codes and M codes .

Important note:Many machine tools have limitations as to how many G or M-codes you may have in one line. One way to eliminate putting in all of these lines is to write a macro program and place the beginning code in the macro. That way only one Code will need to be placed in each program to call all the functions. Example Program with safety code

How to change tools. CNC cutting tools are changed using the M06 command. On some machines (usually older CNCs), the T code will cause the machine to perform a tool change. Check your machine manual to know how your machine will react.Grbl, an open-source, high-performance software used for controlling CNC devices, utilizes a select list of G-code commands to provide an efficient and reliable means of operating these machines. Grbl’s G-code command list .

G Codes List. Here is a list of common G codes. Take note that although most G codes are universal, these specific G codes are what you will find on a Haas machine, and your specific machine may vary some: G00 RAPID POSITIONING MOTION (X,Z,U,W,B) G01 LINEAR INTERPOLATION MOTION (X,Z,U,W,B,F) G01 CHAMFERING AND CORNER ROUNDING .

The G43 command tells the CNC machine to turn on tool length compensation, and the H code (height) informs it of the amount to compensate. The H offset numbers are entered during setup and stored in the machine’s .HYUNDAI WIA Machine Tools: CNC Turning Centers, Vertical M/C, Horizontal M/C, FA, Line Center, F500PLUS, HS5000M/50, LM1800TTSYA CNC machine that operates on wood CNC machines typically use some kind of coolant, typically a water-miscible oil, to keep the tool and parts from getting hot. A CNC metal lathe with the door open.. In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such .

Turning is one of the oldest machining procedures going as far back as the Egyptian empire. CNC turning tools work with a lathe (turning machine) that rotates the workpiece at high revolutions per minute while the turning tool shapes the workpiece into the programmed shape. The shape of the workpiece depends on the type of turning procedure and the turning tool used. G-code is a type of CNC programming language used for controlling the functions of a CNC machine that relate to the movement of the cutting tool.. It stands for ‘Geometric code’. G-code consists of instructions that the microcontroller in the CNC machine can read and interpret. The instructions are then passed to the relevant machine part.

sheet metal rack system

The Bantam Tools Desktop CNC Milling Machine and Bantam Tools Desktop PCB Milling Machine uses the Synthetos TinyG motion control board. It supports the following G-code and M-code commands. Full TinyG reference list (copied from the Synthetos wiki)

sheet metal pumpkins

Here is our Ultimate Guide to CNC Codes. Below is a list of CNC codes with a description of what they are. . M06 will cause the CNC to swap the currently loaded tool with the one selected with the T code. Some machines do not require the use of a M06 code and will swap tools by simply using the T code.Section 2: G-Code Commands for Tool Movements\ In this section, we will dive into the specific G-Code commands that control tool movements, such as linear interpolation, circular interpolation, and helical interpolation. . cnc machine g-code list. On demand manufacturing online CNC Machining Services.

Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series Geometric code (RS-274D) is the most common CNC programming code. This CNC machine code comprises alphabetic codes that symbolize specific commands for the machine. Most G-code programs are written in alphanumeric format, beginning with G, which means geometry. . G04 – Dwell: The G04 code instructs the CNC tool to pause at its present .

In addition Okuma supplies factory automation products and servo motors. Japan's largest machine tool production gantry machining center manufacturer, with a hundred years of machine tool manufacturing experience. Okuma Co., Ltd. is one of the Japanese and CNC machine tool manufacturers. It has a history of more than 100 years.

complete g code list

Design, Drawing, Fabrication & Welding. A complete metalwork service for all of your needs. We are equipped to design and fabricate bespoke guarding to fit your existing machinery. To take the hassle out of the process we offer free quotations for any guarding requirements.

cnc machine tools code list|cnc milling g codes list