cnc machine for carbon fiber We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the. Metal Fabricators of Zambia Plc (ZAMEFA) manufactures and markets copper rods and copper and aluminium electrical conductors in Zambia and for international export.

0 · water jet cutting carbon fiber

1 · how to cut carbon fibre

2 · end mill for carbon fiber

3 · desktop cnc for carbon fiber

4 · cnc carbon fiber sheets

5 · cnc carbon fiber cutting service

6 · carbon fiber machining near me

7 · carbon fiber cnc cutting

ABCs: The Letter Z Song | The final letter in the alphabet. Letter Z! Join Jacinta as she sings all about the Letter "Zed". This video uses UK pronunciatio.

electrical switch box positions

water jet cutting carbon fiber

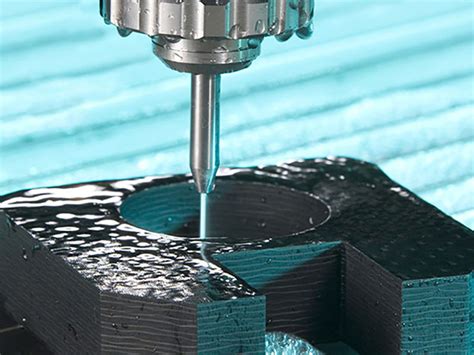

The precision, accuracy, and efficiency of CNC machines make them invaluable tools in industries that rely on carbon fiber for high-performance applications. By investing in the right CNC .Carvera Air offers true 4th axis simultaneous machining, allowing you to create real 3D stereo models like 3D printers. Materials do not limit you; you can craft beautiful, realistic CNC projects with precision, whether plastic, wood, even . CNC Router: This carbon fiber machining tool guarantees precision and high speed due to its high degree of automation. You can tailor it to trim, drill, or shape your workpieces using this high-speed tool.

how to cut carbon fibre

Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are .

We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the. FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic .

Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre . Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.

The precision, accuracy, and efficiency of CNC machines make them invaluable tools in industries that rely on carbon fiber for high-performance applications. By investing in the right CNC machine, manufacturers can achieve clean and precise cuts, minimize .Carvera Air offers true 4th axis simultaneous machining, allowing you to create real 3D stereo models like 3D printers. Materials do not limit you; you can craft beautiful, realistic CNC projects with precision, whether plastic, wood, even metal. CNC Router: This carbon fiber machining tool guarantees precision and high speed due to its high degree of automation. You can tailor it to trim, drill, or shape your workpieces using this high-speed tool. Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are especially popular in .

We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the. FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic system. You can also use added ceramic or metal powders as reinforcements. Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre parts. This tutorial will assist those wishing to learn how to cnc carbon fibre.DragonPlate has been CNC machining carbon fiber parts for our customers for many years. Parts have included radar components for the Department of Defense, racing parts for Ducati super bikes, structural components for UAVs and reinforcements for stringed musical instruments.

Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes. Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.The precision, accuracy, and efficiency of CNC machines make them invaluable tools in industries that rely on carbon fiber for high-performance applications. By investing in the right CNC machine, manufacturers can achieve clean and precise cuts, minimize .Carvera Air offers true 4th axis simultaneous machining, allowing you to create real 3D stereo models like 3D printers. Materials do not limit you; you can craft beautiful, realistic CNC projects with precision, whether plastic, wood, even metal.

CNC Router: This carbon fiber machining tool guarantees precision and high speed due to its high degree of automation. You can tailor it to trim, drill, or shape your workpieces using this high-speed tool.

Carbon fibers are lightweight composites known for their high strength, low weight, durability, impact resistance, and many other beneficial properties for countless industrial applications. These composite parts are especially popular in . We use Autodesk Fusion 360, configure the CAM settings, generate the G-Code, setup the Stepcraft router and then start the machining process. .more. Detailed video tutorial covering all the.

FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic system. You can also use added ceramic or metal powders as reinforcements. Detailed tutorial explaining how to generate toolpaths using Autodesk Fusion 360, configure CAM setting and a desktop CNC router to make your own precision cut carbon fibre parts. This tutorial will assist those wishing to learn how to cnc carbon fibre.DragonPlate has been CNC machining carbon fiber parts for our customers for many years. Parts have included radar components for the Department of Defense, racing parts for Ducati super bikes, structural components for UAVs and reinforcements for stringed musical instruments.

end mill for carbon fiber

desktop cnc for carbon fiber

electrical terminal box hs code

electrical thru-wall box

I believe Yorktown tool boxes were made in Lakewood/Jamestown NY and subsequently bought out by Matco. Matco operates a tool box plant in Lakewood NY. I believe the owner of Yorktown later went back in the business of producing tool boxes under the name of "Aero Industries" but are now defunct.

cnc machine for carbon fiber|desktop cnc for carbon fiber