cnc machine injuries Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company . Services - Western Sheet Metal Inc. – Full-service metal fabrication solution

0 · safety of cnc machinery

1 · cnc machine shop safety

2 · cnc machine safety problems

3 · cnc machine safety examples

4 · cnc machine hazards

5 · cnc cutting machine safety

6 · are cnc machines dangerous

7 · accidents in cnc machines

We’ll break down the categories of electrical boxes and explain their uses. Heath Eastman, an electrical expert at This Old House, discusses the differences between electrical boxes. Types of Electrical Boxes. Electrical boxes come .

Machining and metalworking shops can be dangerous places to work, with a wide variety of potential accidents waiting for workers who are unaware, unalert, or unprepared. From chemical spills and fires to severe . Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving .

The most common injuries associated with CNC machines include lacerations, amputations, eye injuries from flying debris, and hearing damage due to noise. Crushing injuries and burns from hot materials or coolants are also .

metal shutter dog for brick house

CNC machines are highly sophisticated and programmable tools used in various industries for precise machining operations. While these machines offer automation and efficiency, it’s crucial to prioritize safety to . Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company .In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the .CNC machine safety is about reducing the risk of accidents and injuries caused by computer numerical control (CNC) equipment like mills, drills, lathes, and routers. From moving parts, .

Neglecting safety protocols can lead to severe consequences, including accidents, injuries, and damage to equipment. In this article, we will delve into six essential rules that are .

safety of cnc machinery

Learn what to do, and what not to do, to keep yourself safe when you operate CNC machinery. Computer numerical control (CNC) machines are generally safe. But worker misuse can easily . Machining and metalworking shops can be dangerous places to work, with a wide variety of potential accidents waiting for workers who are unaware, unalert, or unprepared. From chemical spills and fires to severe lacerations and even possible amputations, the .

Even with modern protection features, CNC machines can still pose a hazard to workers. Here are 5 critical safety tips to help keep operators out of danger. Using powerful equipment safely is essential for preventing workplace injuries. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

The most common injuries associated with CNC machines include lacerations, amputations, eye injuries from flying debris, and hearing damage due to noise. Crushing injuries and burns from hot materials or coolants are also reported.

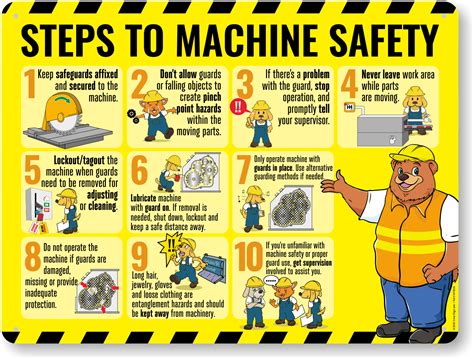

CNC machines are highly sophisticated and programmable tools used in various industries for precise machining operations. While these machines offer automation and efficiency, it’s crucial to prioritize safety to avoid accidents, injuries, and equipment damage. Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company-wide safety program.

In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the implications of these incidents and shed light on the significance of safety protocols in CNC machine operations.

CNC machine safety is about reducing the risk of accidents and injuries caused by computer numerical control (CNC) equipment like mills, drills, lathes, and routers. From moving parts, hot surfaces, slippery fluids, and sharp edges to sparks, chips, and noise, CNC machinery can put unprotected workers at risk. Neglecting safety protocols can lead to severe consequences, including accidents, injuries, and damage to equipment. In this article, we will delve into six essential rules that are paramount for maintaining a safe working environment when operating CNC machinery.Learn what to do, and what not to do, to keep yourself safe when you operate CNC machinery. Computer numerical control (CNC) machines are generally safe. But worker misuse can easily jeopardize their safety. That’s why it’s important for their operators to know exactly what they should – and should not – do.

Machining and metalworking shops can be dangerous places to work, with a wide variety of potential accidents waiting for workers who are unaware, unalert, or unprepared. From chemical spills and fires to severe lacerations and even possible amputations, the . Even with modern protection features, CNC machines can still pose a hazard to workers. Here are 5 critical safety tips to help keep operators out of danger. Using powerful equipment safely is essential for preventing workplace injuries.

metal siding colors for houses

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras. The most common injuries associated with CNC machines include lacerations, amputations, eye injuries from flying debris, and hearing damage due to noise. Crushing injuries and burns from hot materials or coolants are also reported. CNC machines are highly sophisticated and programmable tools used in various industries for precise machining operations. While these machines offer automation and efficiency, it’s crucial to prioritize safety to avoid accidents, injuries, and equipment damage. Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company-wide safety program.

In this blog post, we will delve into the world of CNC machine crashes, exploring their causes, the risks involved, and the measures that can be taken to prevent them. Let us uncover the implications of these incidents and shed light on the significance of safety protocols in CNC machine operations.CNC machine safety is about reducing the risk of accidents and injuries caused by computer numerical control (CNC) equipment like mills, drills, lathes, and routers. From moving parts, hot surfaces, slippery fluids, and sharp edges to sparks, chips, and noise, CNC machinery can put unprotected workers at risk.

cnc machine shop safety

cnc machine safety problems

Neglecting safety protocols can lead to severe consequences, including accidents, injuries, and damage to equipment. In this article, we will delve into six essential rules that are paramount for maintaining a safe working environment when operating CNC machinery.

metal shop houses for sale near me

cnc machine safety examples

Common Home Electrical Wiring Boxes and How to Use Them: How to Secect The Right Junction Box for Your Electrical Project with Photos and Detailed Descriptions.

cnc machine injuries|cnc cutting machine safety