cnc milling medical parts CNC milling for medical devices addresses the soaring demands for top-tier, precision-driven medical equipment. This advanced machining . At 1stDibs, there are several options of vintage industrial storage cabinets available for sale. The range of distinct vintage industrial storage cabinets — often made from metal, wood and iron — can elevate any home.

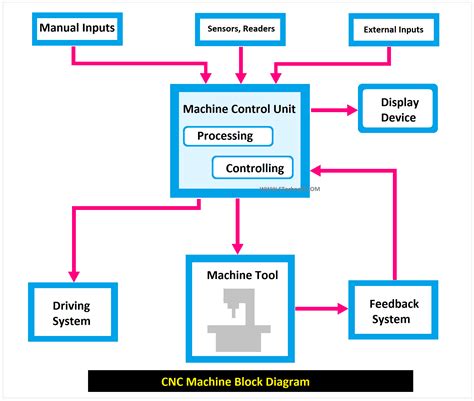

0 · schematic diagram of cnc machine

1 · milling machine parts diagram

2 · homemade cnc parts

3 · cnc milling machine parts names

4 · cnc mill parts diagram

5 · cnc mill diagram

6 · cnc machine parts list pdf

7 · cnc horizontal milling for dummies

Check out our green vintage metal lunchbox selection for the very best in unique or custom, handmade pieces from our lunch bags & boxes shops.

Whether you need parts from 5-axis milling, wire EDM, micromachining or precision manufacturing, the specialized machining capabilities of our CNC machining lathes offer the very best in medical manufacturing services. Medical CNC machining is a specialized process that utilizes computer numerical control (CNC) technology to manufacture precision . CNC milling for medical devices addresses the soaring demands for top-tier, precision-driven medical equipment. This advanced machining .Precision matters in medical CNC machining. Discover our advanced capabilities for manufacturing critical medical components efficiently and effectively.

High precision CNC machined parts and components for medical devices and surgical instruments. Get your instant quote today!In addition to the engine radiator mentioned earlier, some components of the car's wheels and suspension system have also begun to use aluminum CNC milling parts. The CNC milling of wheel hubs can not only achieve beautiful styling .

Learn the basics of CNC milling parts with our comprehensive beginner's guide. Discover how CNC milling works and why it's essential for precision manufacturing. . Medical: Surgical instruments, implants; Getting .Medical CNC Machining Processes and Practices. The CNC machining process for medical applications involves several key steps: 1. Design and CAD Modeling: The process begins with the creation of a CAD model that defines the .

boxer electrical services

In addition to the engine radiator mentioned earlier, some components of the car's wheels and suspension system have also begun to use aluminum CNC milling parts. The CNC milling of wheel hubs can not only achieve beautiful styling design, but also reduce weight while ensuring strength, improving the handling performance and fuel economy of the .

Injection molding, additive manufacturing (3D printing) and CNC machining are common processes for manufacturing medical components. Among them, CNC machining is one of the best options for manufacturing medical prototypes due to its high degree of customization, tight tolerances, excellent surface finish and certified material selection. The versatility of CNC . CNC machining is fast becoming the leading method for manufacturing medical parts. The medical industry requires precise and high-quality components. CNC machining makes it possible to create these parts with a high degree of accuracy, consistency, and speed.We’ve provided custom CNC machined parts for the medical industry since 1972. When you need medical-grade machining, trust Ephrata Precision. We’ve provided custom CNC machined parts for the medical industry since 1972. . Our tried-and-true approach includes CNC milling, 5-axis machining, and EDM machining, all coordinated to achieve the .

CNC Machining & Milling For Medical Parts. Our machines are capable of creating parts with great accuracy. They can also operate extremely rapidly, enabling us to deliver the volume of components you need in time to meet your production schedule. We have invested heavily in our equipment, enabling us to offer 3, 4 and 5 axis CNC milling, Wire .

CNC Milling. CNC milling involves the use of rotary cutting tools to remove material from a workpiece, producing complex parts with high precision. It is widely used for manufacturing a broad spectrum of medical devices, from implants to surgical instruments. . Designing CNC machined medical parts requires a nuanced approach that balances .Custom CNC Milling Aluminum Parts for Medical Devices. Custom CNC milling aluminum parts used for the medical industry – the series of 6061 aluminum alloy parts manufactured by CNCLATHING. Aluminum is commonly used in orthopedic, endoscopic, spine, trauma, surgical instruments, and general hospital equipment, and the preferred choice when making surgical .CNC Machining Parts Supplier, Mold, CNC Milling Parts Manufacturers/ Suppliers - Shenzhen Pans Technology Co., Ltd. Menu Sign In. Join Free For Buyer. Search Products & Suppliers . High Precision Custom CNC Lathe Machining Turning Milling Metal Plastic Parts Hardware Medical Automotive Aerospace Parts. USCNC Milling CNC milling, a precision manufacturing process, offers significant advantages in the production of medical industry components.It enables the creation of complex designs with precise tolerances, ensuring the functionality and reliability of medical devices. CNC milling's ability to process a range of materials and its high production efficiency make it a cost-effective ..001-1.00. 1 Piece (MOQ)

Moreover, this innovative technology is widely used in aerospace, automotive, medical, and consumer goods industries to fabricate high-quality components that meet the most stringent requirements and specifications. . Designing parts for CNC milling involves several key considerations to ensure successful manufacturing. Firstly, the process .Precision CNC machining plays a crucial role in the medical industry, particularly in the production of medical devices and instruments. These specialized machines are able to produce precise and complex parts with a high level of accuracy, making them ideal for creating medical components that require strict tolerances.As an ISO 9001:2015 certified and ISO 13485:2008 compliant company, we are a medical parts specialist. The manufacturing of medical parts requires working with tighter tolerances and unique materials. The top-of-the-line equipment, .

Our machines are capable of creating parts with great accuracy. They can also operate extremely rapidly, enabling us to deliver the volume of components you need in time to meet your production schedule. We have invested heavily in .

Medical parts such as joint implants, cardiovascular implants, and ventricular assist devices have complex geometries. Creating such geometries is often not possible without using 5-axis CNC machining operations while also maintaining required geometric tolerances and surface finish requirements.Home China’s trusted source for high-quality precision CNC milling services, offering competitive pricing and rapid lead times. Upload a Part Certifications : ISO 9001:2015 | AS9100D | ITAR Registered Over 60 Certified Materials Custom Finishes ±0.005mm Tight Tolerance Lead times from 7 days Table of Contents Qualified CNC Milled Parts from reliable manufacturers .

Medical CNC Milling. Xometry offers standard 3- and 4-axis medical CNC milling. Medical CNC milling’s advantage is the rapid turnaround of parts and parts that fall within tight tolerances. Common materials include stainless steel, titanium, .6.Medical Device Prototyping. Before mass producing any medical device, it is critical to create prototypes for testing and validation, and Richconn’s CNC machining provides a fast and cost-effective solution for producing medical device prototypes, whether it is medical CNC turning services or CNC milling services, we can meet your needs.

Richconn custom CNC Machined Parts for Medical manufacturer direct sales, professional customization of various CNC Machined Parts for Medical solutions, whether small batch or large-scale production. . We utilize state-of-the-art CNC milling, turning, and multi-axis machining, delivering complex geometries with the highest tolerances .At CNC Rapid, we specialize in producing high-precision CNC parts for the rapidly evolving medical devices sector. Our advanced CNC milling centers, including 3 axis, 4 axis, and 5 axis machines, enable us to manufacture parts with exceptional accuracy, catering to the stringent requirements of medical innovations.

schematic diagram of cnc machine

CNC Machining for Medical Device Applications. From connected devices to mass personalization of healthcare products, digital manufacturing can accelerate development in many different ways. We offer production-grade materials for functional and regulatory testing of medical parts. Some common components we machine for medical applications include:Our machines are capable of creating parts with great accuracy. They can also operate extremely rapidly, enabling us to deliver the volume of components you need in time to meet your production schedule. We have invested heavily in our equipment, enabling us to offer 3, 4 and 5 axis CNC milling, Wire EDM, CNC Turning, CAD/CAM and CMM inspection.The Fresno, CA medical device industry relies on CNC milling to reliably produce discrete parts in large quantities. Many medical device parts are small, made of exotic materials, and are only designed for a single use as a way to promote cleanliness.Ardel Engineering is proud to supply top-quality custom CNC parts for customers across a wide range of industries, . Ardel also machines specialty plastic parts for critical applications in the medical and telecommunications industries. . offering state-of-the-art machining services through vertical and horizontal CNC milling machines. Our .

box to hold 2x4 galvani steel

The Raleigh, NC medical device industry relies on CNC milling to reliably produce discrete parts in large quantities. Many medical device components are small, made of exotic metals, and are only designed for one use in order to promote good hygiene.

milling machine parts diagram

homemade cnc parts

Get the best deals for Vintage Metal Doll House at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

cnc milling medical parts|homemade cnc parts