13 axis cnc machine Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems. $89.00

0 · multi axis cnc machines

1 · mill xyz axis

2 · cnc axis explained

3 · axis identification in cnc machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc machine price

6 · 12 axis cnc mill

7 · 12 axis cnc machine price

Wardrobe Clothing Moving Boxes with Metal Hanging Bar, 24 x 24 x 40 Inches, .

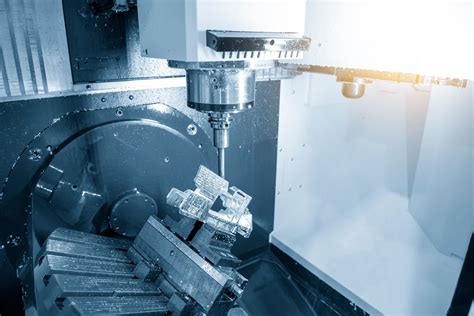

The 13-axis CNC machine combines the versatility of a multi-axis system with enhanced precision, speed, and efficiency. Unlike traditional CNC machines that operate with 3 or 5 .

Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.The 13-axis CNC machine is here to stay and shine brightly in the vast sky of precision manufacturing. It undoubtedly holds a promising future in manufacturing by enabling . COMPARING MULTI-AXIS CNC MACHINES. So, what makes each multi-axis CNC machine different from one another? Here’s a summary of how each machine, from 3-axis to .

In this guide, we cover each type of CNC machine, like mills, lathes, plasma cutters, and more and discuss their uses, prices, and must-have featuresA 7-axis CNC machine can cut from multiple sides simultaneously, increasing throughput. They can handle more complex geometries, including contoured surfaces, tapered features, and an increasing range of undercuts that are .In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.The 13-axis CNC machine combines the versatility of a multi-axis system with enhanced precision, speed, and efficiency. Unlike traditional CNC machines that operate with 3 or 5 axes, the 13-axis machine incorporates additional axes for simultaneous movement of multiple tools, enabling complex operations and reducing production time.

Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.The 13-axis CNC machine is here to stay and shine brightly in the vast sky of precision manufacturing. It undoubtedly holds a promising future in manufacturing by enabling production processes that were otherwise considered difficult or impossible. COMPARING MULTI-AXIS CNC MACHINES. So, what makes each multi-axis CNC machine different from one another? Here’s a summary of how each machine, from 3-axis to 12-axis machines, stack up against each other. 3-axis CNC. The 3-axis CNC machine was the first leap for CNC machines from rotary filing technique.

In this guide, we cover each type of CNC machine, like mills, lathes, plasma cutters, and more and discuss their uses, prices, and must-have featuresA 7-axis CNC machine can cut from multiple sides simultaneously, increasing throughput. They can handle more complex geometries, including contoured surfaces, tapered features, and an increasing range of undercuts that are impossible in simpler machines.Tsugami has mounted an articulated B-axis vertical spindle inside their proven Swiss Type CNC lathe platform to deliver a compact machining center capable of producing complex parts by performing CNC milling, drilling, tapping, compound angle work, turning, boring, and threading in a . Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

7-axis CNC machining offers much better benefits than 5-axis CNC machining, such as increased precision, accuracy, time, and cost savings with the added advantage of increased versatility. It enables manufacturers to create complex parts with intricate details in a single setup, eliminating any need for manual reorientation or additional setups.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.The 13-axis CNC machine combines the versatility of a multi-axis system with enhanced precision, speed, and efficiency. Unlike traditional CNC machines that operate with 3 or 5 axes, the 13-axis machine incorporates additional axes for simultaneous movement of multiple tools, enabling complex operations and reducing production time. Learn about CNC machine axis counts, including the types of axes and how they are incorporated in the creation of 2-axis, 3-axis, 4-axis, and 5-axis CNC systems.

multi axis cnc machines

The 13-axis CNC machine is here to stay and shine brightly in the vast sky of precision manufacturing. It undoubtedly holds a promising future in manufacturing by enabling production processes that were otherwise considered difficult or impossible. COMPARING MULTI-AXIS CNC MACHINES. So, what makes each multi-axis CNC machine different from one another? Here’s a summary of how each machine, from 3-axis to 12-axis machines, stack up against each other. 3-axis CNC. The 3-axis CNC machine was the first leap for CNC machines from rotary filing technique.

In this guide, we cover each type of CNC machine, like mills, lathes, plasma cutters, and more and discuss their uses, prices, and must-have features

A 7-axis CNC machine can cut from multiple sides simultaneously, increasing throughput. They can handle more complex geometries, including contoured surfaces, tapered features, and an increasing range of undercuts that are impossible in simpler machines.Tsugami has mounted an articulated B-axis vertical spindle inside their proven Swiss Type CNC lathe platform to deliver a compact machining center capable of producing complex parts by performing CNC milling, drilling, tapping, compound angle work, turning, boring, and threading in a . Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses.

mill xyz axis

math calculations for sheet metal fabrication

materials from metal that can be woven into fabric

cnc axis explained

8 talking about this

13 axis cnc machine|cnc axis explained