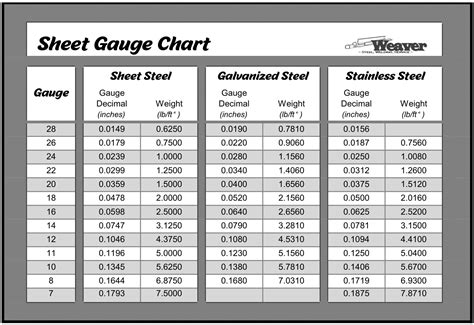

18 gauge sheet metal thickness tolerance The following charts give typical ASTM and ANSI steel sheet mechanical tolerance . Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting. There are several galvanizing processes available, but the most commonly offered and used method is called hot-dip galvanizing.

0 · sheet metal gauge thickness chart

1 · how thick is 18ga metal

2 · how thick 18 gauge metal

3 · gauge to inches calculator

4 · 18 gauge thickness in inches

5 · 18 gauge steel thickness inches

6 · 18 gauge stainless steel thickness

7 · 18 gauge is how thick

Metal fabrication is a manufacturing process used to shape metal into end products. Learn about the industries that use it and the advancements in it.

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .The following sheet metal gauge size reference chart gives the weight and . The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing . The following sheet metal gauge size reference chart gives the weight and thickness .Sheet metal thickness tolerances for Austenitic, Ferritic and Martensitic Stainless steels. You can use this sheet metal data table for all the common commercial grades of stainless steel such .

Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for .These measurements are based on ASTM A924/924M-94, Standard Specification for General Requirements for Sheet Steel, Metallic Coated by the Hot-Dip Process (formerly ASTMA525); .For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” .The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing . The thickness of 18-gauge sheet metal is 0.0478 inches (1.214 mm) thick specifically as per the Manufacturer’s standard gauge steel sheet. The need for Ra .The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .Sheet metal thickness tolerances for Austenitic, Ferritic and Martensitic Stainless steels. You can use this sheet metal data table for all the common commercial grades of stainless steel such as 304, 316 and 430. These are the most common grades asked for by our customers when wanting sheet metal fabrications.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.

These measurements are based on ASTM A924/924M-94, Standard Specification for General Requirements for Sheet Steel, Metallic Coated by the Hot-Dip Process (formerly ASTMA525); and ASTMA653/A653M-94, Standard Specification for Sheet Steel, Zinc-Coat (Galvanized) or Zinc-Iron Alloy Coated (Galvanized) by the Hot-Dip Process.For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.AISI Thickness Tolerance Ranges Galvanized Steel Sheets Thinkness. inches lbs. per sq.ft. Thinkness. . 18 .0516 .0566 .0466 2.15625 29 .0172 .0202 . Weight equivalents based on density of .2904 lb. per cubic inch Gages 10, 11, 12 – tolerances shown are for widths over 40” to 60” inclusive All other gages – tolerances shown are for .

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing . The thickness of 18-gauge sheet metal is 0.0478 inches (1.214 mm) thick specifically as per the Manufacturer’s standard gauge steel sheet. The need for Ra .The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .Sheet metal thickness tolerances for Austenitic, Ferritic and Martensitic Stainless steels. You can use this sheet metal data table for all the common commercial grades of stainless steel such as 304, 316 and 430. These are the most common grades asked for by our customers when wanting sheet metal fabrications.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.

house numbers in metal

These measurements are based on ASTM A924/924M-94, Standard Specification for General Requirements for Sheet Steel, Metallic Coated by the Hot-Dip Process (formerly ASTMA525); and ASTMA653/A653M-94, Standard Specification for Sheet Steel, Zinc-Coat (Galvanized) or Zinc-Iron Alloy Coated (Galvanized) by the Hot-Dip Process.For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.

sheet metal gauge thickness chart

how thick is 18ga metal

how thick 18 gauge metal

Industrial metal fabrication refers to the manufacturing process of creating metal structures, parts, and products used in various industries, such as construction, automotive, aerospace, and more. It involves various techniques and .

18 gauge sheet metal thickness tolerance|18 gauge is how thick