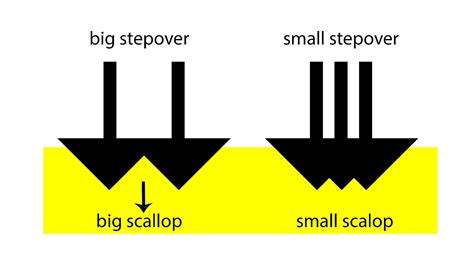

cnc machining step over calculation For example, a 1mm step over with a 25.4mm ball end mill will produce about a .01mm tall scallop, while a 12.7mm ball end mill will produce about a .02mm scallop height with a 1mm step over. An electrical box, also known as a junction box, is an essential component in electrical installations. It serves as a protective enclosure for electrical connections, ensuring .

0 · stepover for cnc machining

1 · stepover cnc meaning

2 · stepover 3d cnc

3 · step over milling distance calculator

4 · step over cnc

5 · cnc stepover percentage

6 · best stepover in cnc

7 · 3d profiling stepover calculator

A Septic Tank Distribution Box, also known as a D-box, is a junction box positioned between the septic tank and the drain field (or leach field). Its primary function is to evenly distribute the effluent (wastewater) from the septic tank .

Milling Step-over Distance Calculator. In many milling operations, the cutting tool must step over and make several adjacent cuts to complete machining a feature.

For example, a 1mm step over with a 25.4mm ball end mill will produce about a .01mm tall scallop, while a 12.7mm ball end mill will produce about a .02mm scallop height with a 1mm step over. To get the amount of control needed to produce repeatable surface finishes, you probably need to automate. Both of Comco’s systems, the Advanced Lathe and the JetCenter, provide careful control over particle velocity and . One of the fundamental parameters of any CNC machining, and 3D machining in particular, is the stepover. It is not a stretch to say that it is the single most important parameter in determining the quality of the finished parts . I've been using a 3/8 ball em in alum. It seams like 10% of the diameter is a good roughing step over. I'm going to try 5% step over for finishing. 3% of em diameter gave a good .

For example, a 1mm step over with a 25.4mm ball end mill will produce about a .01mm tall scallop, while a 12.7mm ball end mill will produce about a .02mm scallop height with a 1mm step over. If you decrease the step .

stepover for cnc machining

stepover cnc meaning

Try out our Machinist Calculators to get the exact fit you need. Provided by Villa Machine Associates. Call us today at (781) 326-5969 or more info. . The “SURFACE FINISH” calculator also includes a stepover adjustment calculator . Cusp height vs step over Allot depends on your CAM system. If you have steep vertical walls you will want your step over to be based on your part shape, this usually takes longer to calculate, but you don't get the water fall effect when cutter path is based on a plane. I usually use cusp or scallop height (which ever you CAM system calls it).Milling Step-over Distance Calculator CustomPart.Net. Tool diameter (in): Step-over distance (in): Scallop height (in):Clamping Stability: Try to estimate the overall combined stability of your tool and workpiece.If you are unsure, leave it as “average”. Excellent: The workpiece is firmly clamped and supported and the tool is firmly clamped with a short overhang. Poor: The workpiece L/D factor is large (Long shafts) without a steady rest (Luneta) and/or tailstock and/or the tool has a long overhang.

Optimize your CNC machining cycle time with our calculation guide. Learn about CNC machining, estimating time, and examples. Explore our services now! 866-765-9191. Contact Info; Mission Statement; 866-774-9353; . Length = Tool Approach + Job Length + Tool Over Travels x Number of Passes; ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. A machinist can pick a value by feel, based on previous experience, or do the math and calculate the exact value that will give them the finish required. New users generally don’t have the experience and don’t know the math so it takes a while to get an intuitive understanding of of the stepover parameter.

Six main reasons to calculate CNC machining cycle and lead times are: . If the length of cut required is 10 inches and the tool needs to pass over the workpiece 3 times, the cycle time calculation would be: . Step-by-Step Calculation: Time to Drill One Hole: To calculate the time it takes to drill one hole, you divide the drilling depth by . Surface finish calculators; imperial, scallop height, step over, tool diameter or tip radius

stepover 3d cnc

G-Wizard’s Plunge Milling Calculator let’s us enter a Step Up (amount to move into material at start of each pass) and a Step Over (amount to move laterally from prior hole on the same pass) and adjusts the feedrate based on those parameters. Here is the result: Here’s a case where Plunge Milling shines.Thanks to our friends at custompartnet.com, Xometry is now a one-stop shop for milling, drilling and turning calculators.Whether you need speeds & feeds, horsepower, step-over distance, or roughness, we have you covered. Milling Speed & Feed Calculator Milling Speed and Feed Calculator Milling Horsepower Calculator Milling Horsepower Calculator .

How much of the radius from tool did not cut to Z 0 So for every .05 step there would be a rise from ball on tool of .00125 and if your looking for a smooth surface with this step over you will be hand sanding ***** Cusp Height / Cutter Stepover Calculation ***** Tool Radius = 0.25 Cutter Stepover = 0.05 Cusp Height = 0.00125 GWizard Machinist's Calculator will let you play with these numbers. . . and us a 5-10% step over to keep the endmill from only wearing on the bottom.Gotta use the whole length of the cutter. D. DMF_TomB Diamond. Joined . CNC Machining; Replies 2 Views 2K. Apr 25, 2024. maccie. M. B.Units used in the above table: A p, A e, D, W – mm or Inch; V f – m/min or inch/min; V c – m/min or feet/min (SFM); F n – mm/rev or Inch/rev; MRR – Metal Removal Rate CM 3 /min or Inch 3 /min; Step 2 – Obtaining the materials . Learn step-by-step as CNC master technician Jeff thoroughly explains how to calculate feeds and speeds for your CNC machine. Read full transcript here: http.

fancy metal stamped brackets

This process is integral to manufacturing because it allows for high accuracy, repeatability, and complex geometries that manual machining cannot achieve. Step-by-Step CNC Machining Process 1. Designing the CAD Model. The first . Use Cutting Speeds And Feeds Calculator with simple shop formulas and access a full-featured, industry-leading calculator (free for a limited time). Thousands of top manufacturers rely on it daily. . worked with over 50,000 CNC'ers like yourself to make sure you'd have the Best Feeds and Speeds. . Video: CNC Router as Pick and Place Machine.Engineers apply the knowledge of math & science to design and manufacture maintainable systems used to solve specific problems. AskEngineers is a forum for questions about the technologies, standards, and processes used to design & build these systems, as well as for questions about the engineering profession and its many disciplines.Steps/mm (steps per millimetre) settings determine how far a CNC machine moves when instructed to travel a specific distance. . Modify Step Per mm Settings: Change the "Steps Per mm" setting . Current Steps Per mm: 80; Expected Distance (mm): 100; Actual Distance Traveled (mm): 98; Click "Calculate" and the calculator will provide the new .

CNC Machining . CNC milling help with longer end mills step over and depth of cut calculations . So how would I calculate the step over like lets say I have a 200mm long cutter and want to use the whole 200mm how would I go about this. there must be some type of formula that includes the tool length. because I still work on the basics of half . Model of CNC Machine: TinyG - Homemade. stepover percent during final finish. Post by auga » Wed Jun 28, . Using a .09375 radius .1875 dia ballnose with 10% (.0188") step over this Moose Model came out rather well - little light sanding to no sanding is all that is needed! moose.jpg. Sharkcutup. Latest Post. What Software Do CNC Machines Use: A Comprehensive Guide December 9, 2023 - 5:28 am; What Language Do CNC Machines Use? A Comprehensive Guide December 9, 2023 - 2:29 am; What is CNC Welding Machine: A Comprehensive Guide December 8, 2023 - 11:28 am; CNC Machine Operator Salary: What You Need to Know December 6, .

CNC Machining . Deep w/ light stepover or shallow w/ heavy . I'd calculate the cubes with the machine maxed out each way. The one that comes up with more cubes is the winner. N. . With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist .Check out the Turning Calculations included within CNC Machinist Calculator Pro. They include spindle speed calculations, cut time calculations and more . Blue Print GD&T 17. Machinability & cutting speed data for over 180 materials 18. Tap Drill Calculator for roll form & cut taps 19. Geometric calculators 20. Triangle Solver 21. Angle .

I understand that the m/c will take care of the math once I give the comp. But for my knowledge i wanted to know the calculation. Also I have a very silly question to ask here. I came across a CNC lathe program where they do the machining in the following sequence. 1.Rough facing and turning 2. drilling 3. Boring 4. Finish turning.I'd use a new good quality small bull nose. I'd run my finishing pass as a constant step over and rather than start from the middle or outside and follow the shape I'd run the pass at 45 degrees with a small step over say .1mm, less if I have time. I'd also consider starting the passes from the same side so going from x - y - to x y.

step over milling distance calculator

Sheet metal hem radius, there is only one 180-degree bend in a hem. Some hems are closed, which means that the inside bend radius is zero. The hem’s cross-section resembles a U if its .

cnc machining step over calculation|cnc stepover percentage