attaching sheet metal parts In this post, we'll compare some of the most common techniques for joining sheet metal parts: Tapping involves cutting threads directly into the sheet metal to allow for screw . Working Principle: The lathe is a machine tool which holds the workpiece between two rigid and strong supports called centers or in a chuck or face plate which revolves. The cutting tool is rigidly held and supported in a tool post which is fed against the revolving work.

0 · sheet metal welding process

1 · sheet metal joining technology

2 · sheet metal joining techniques

3 · sheet metal joining screws

4 · sheet metal joining process

5 · sheet metal connection process

6 · how to join sheet metal parts

7 · clinching joint sheet metal

Pillar manufactures a line of CNC machinery for secondary and special processing of solid wood and panel components. My company relies on Pillar to provide a quality product to my customer and they have schedule, service, and communication.$399.99

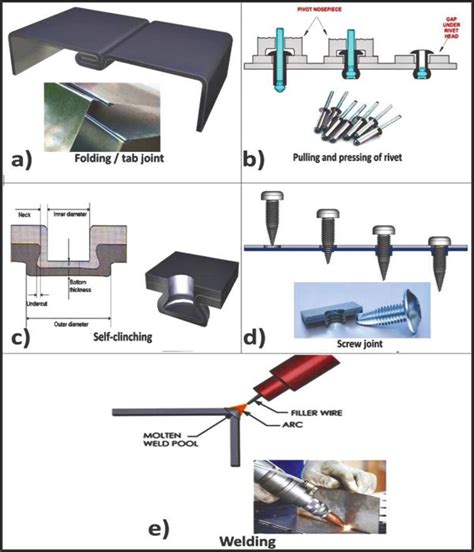

Sheet metal joining refers to the process of connecting different sheet metal parts through specific techniques during sheet metal fabrication, aiming to achieve the functionality and performance of the overall structure.How can we ensure secure and durable connections in sheet metal fabrication? . In this post, we'll compare some of the most common techniques for joining sheet metal parts: Tapping involves cutting threads directly into the sheet metal to allow for screw .Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and .

How to fasten sheet-metal parts without fastening hardware. Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in sheet-metal. Appliance engineers have several options for joining sheet metal, including screws, rivets, welding, bonding, clinching and folding. Which is best depends on the material, its thickness and the application requirements. Most .Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. At Shengen, we understand the nuances of sheet metal .Metal assembly is the process of joining sheet metal parts together to create a final product. This can involve different methods such as welding, adhesives, rivets, or threaded fasteners. At Precision Machine Fabrication, we offer .

Sheet metal joining refers to the process of connecting different sheet metal parts through specific techniques during sheet metal fabrication, aiming to achieve the functionality and performance of the overall structure.Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications. In this post, we'll compare some of the most common techniques for joining sheet metal parts: Tapping involves cutting threads directly into the sheet metal to allow for screw attachment. This method works well for thicker gauges and provides a clean, flush connection.

Well, this guide explores some of the most common top 11 sheet metal assembly options to choose from. 1. Assembling Sheet Metal With Fasteners i.e. Nuts & Screws. 2. Welding Sheet Metal. 3. Sheet Metal Rivet Assembly. 4. Soldering And Brazing Sheet Metal Assembly. 5. Assemble Sheet Metal With Tongue And Groove. 6. How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You'll discover the pros and cons of each method, practical applications, and how they contribute to the strength and integrity of metal structures.Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and groove connections, adhesives, hemming, snap fits, clinching, tabs, and hinges.

How to fasten sheet-metal parts without fastening hardware. Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in sheet-metal. Appliance engineers have several options for joining sheet metal, including screws, rivets, welding, bonding, clinching and folding. Which is best depends on the material, its thickness and the application requirements. Most engineers rely heavily on mechanical fasteners.Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. At Shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Stick around, and I’ll share our pearls of wisdom.Metal assembly is the process of joining sheet metal parts together to create a final product. This can involve different methods such as welding, adhesives, rivets, or threaded fasteners. At Precision Machine Fabrication, we offer electro-mechanical assembly services to customers who require a more complete product upon delivery.

sheet metal welding process

Sheet metal joining refers to the process of connecting different sheet metal parts through specific techniques during sheet metal fabrication, aiming to achieve the functionality and performance of the overall structure.Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications. In this post, we'll compare some of the most common techniques for joining sheet metal parts: Tapping involves cutting threads directly into the sheet metal to allow for screw attachment. This method works well for thicker gauges and provides a clean, flush connection. Well, this guide explores some of the most common top 11 sheet metal assembly options to choose from. 1. Assembling Sheet Metal With Fasteners i.e. Nuts & Screws. 2. Welding Sheet Metal. 3. Sheet Metal Rivet Assembly. 4. Soldering And Brazing Sheet Metal Assembly. 5. Assemble Sheet Metal With Tongue And Groove. 6.

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You'll discover the pros and cons of each method, practical applications, and how they contribute to the strength and integrity of metal structures.

Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and groove connections, adhesives, hemming, snap fits, clinching, tabs, and hinges.

How to fasten sheet-metal parts without fastening hardware. Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in sheet-metal. Appliance engineers have several options for joining sheet metal, including screws, rivets, welding, bonding, clinching and folding. Which is best depends on the material, its thickness and the application requirements. Most engineers rely heavily on mechanical fasteners.

Riveting sheet metal is all about using a metal pin or bolt to join two pieces of metal. It’s a permanent fastening method, ensuring the parts won’t part ways anytime soon. At Shengen, we understand the nuances of sheet metal fabrication and the importance of getting it right. Stick around, and I’ll share our pearls of wisdom.

simpson sheet metal santa rosa ca

sheet metal joining technology

Maintain an organized workstation with this WorkPro lateral drawer file cabinet. Steel construction with a sleek finish offers a simple modern look, while the drawers provide ample space for .

attaching sheet metal parts|sheet metal joining techniques