cnc machining finishes You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of metal parts. Learn about the most common ways to finish CNC machined parts, and how to select the best methods for your applications. Top Considerations for CNC Machining Large Parts CNC machines are very versatile for product manufacture and precision machining. Relative to 3D printing, CNC machines can deliver large size parts with amazing accuracy and finish. More often than not, parts to be CNC machined will fall within the capacity of the device. In few instances, the . Top .

0 · surface finish standards chart

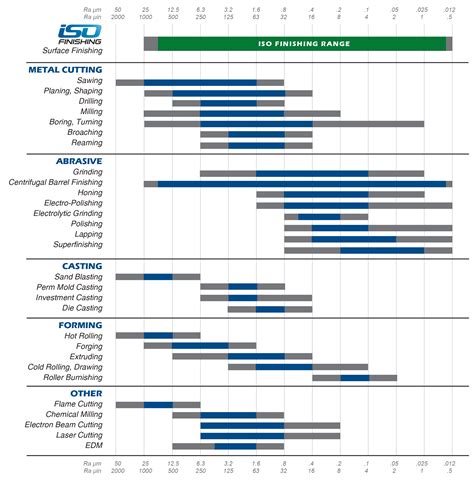

1 · surface finish by machining process

2 · metal finishing specifications chart

3 · machining finishes chart

4 · machined plastic surface finish chart

5 · machine finish symbols chart

6 · honing surface finish chart

7 · casting surface finish chart

Get the look of traditional metal roofing with Clicklock Premium Standing Seam. The Visualizer Tool will help you find the right style of metal roofing shingles for your home. What Color of Metal Roof?

You can apply post-processing and surface finishes to improve the surface roughness, cosmetic properties and wear resistance of metal parts. Learn about the most common ways to finish CNC machined parts, and how to select the best methods for your applications. Some of the key factors to consider when selecting a CNC machining surface finish include functionality, material, aesthetics, cost, lead time, environmental impact, and part geometry. By carefully evaluating these . CNC machining surface finishing is a complex field that requires attention to detail, from preparation through to the final application of the finish. Understanding common problems and how to prevent them ensures high .This article will explore some of the most popular finishes for CNC machining, from sandblasting to painting and everything in between. By understanding the benefits of each method, you can choose the right finishing option for your .

Surface finishes like sanding, polishing, electroplating, or painting help conceal sharp edges and machining marks left behind during CNC machining procedures. As a result, these surface finishing treatments make .Diamond Tools. Diamond tools can be considered the ideal choice for achieving the best surface finish for non-ferrous materials. These tools are designed specifically for finishing operations only and can be a true game changer when . Surface finish is one of the most important aspects of CNC machining as it improves appearance and influences functionality. There are several types of surface finishes, . Learn about the surface finishing options for CNC parts, from anodizing and Chem film or Alodine™ to zinc plating and electropolishing.

CNC machining surface finish, on the other hand, describes the state of the finished parts’ surface, as well as the process involved in achieving that state. It refers not only to the texture or look of the surface but also to the overall .Learn to design better parts for 3D printing, CNC machining, injection molding and sheet metal fabrication. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . Post-processes & finishes. Understanding materials for manufacturing and how to get the most out of the last step of the manufacturing process? Read moreMachining surface finish influences the quality, durability and performance of manufactured parts and components. . CNC machining including tuning, drilling, planning, grinding and boring for visible and direction-blurred tool marks. 8: .Learn more about Surface Finishes Chart for CNC Machining Symbols and Standards. Surface finishing symbols on the other hand serve a slightly different function in industrial operations. They visually designate the results of a machining process to specify the processes employed for a specific surface finish. The main purpose is to help find .

Understanding the Role of Metal Type. Different types of metals‘ physical and chemical properties are distinct and affect the different finishing operations in varying degrees of effectiveness. For instance, steel, the most common ferrous metal, usually goes through galvanizing in order to prevent screen damage since it rusts very quickly owing to its iron .A CNC machined part isn’t done once the machine stops running.. Finishing is the final step in the manufacturing process (outside of assembly) and involves various techniques to improve your parts’ appearance, functionality, and durability. The finishing process is crucial to achieving the desired properties of your machined parts. This article will explore some of the most popular .

CNC Machining Service. CNC Milling CNC Turning Production Machining Precision Machining Threading Options Finishing Options. 3D Printing Service. . Anodizing helps parts resist scratching, is a natural electrical insulator, and is one of the most durable finishes available. We offer three specific types of quick-turn anodizing options to .Understanding CNC Machining Surface Finishes. Before we dive into how to choose the best tools for your project, it’s important to understand what CNC milling surface finishing means. Surface finish refers to the texture or quality of the surface of a machined part. This is determined by factors such as toolpath strategies, cutting parameters . Precision machining entails very exact craftsmanship, with numerous steps that must be completed accurately to achieve the desired results. With CNC machining, surface finishes are the final process in fabricating a product that will perform optimally. Machining finishes provide numerous advantages, including augmenting conductivity, improving appearance, . For all our CNC machined parts we produce, we have certain standards we ensure for our deburring and primary surface finishes which include smooth machining, bead blasting, brushing, polishing, and brushed and electropolished. These standards are listed below so you know what to expect when you order CNC machined parts from Protolabs Network.

CNC Machining Surface Finishes. As machined. Parts are machined and deburred, sharp edges are chamfered. Visible machining marks, light surface scratches. Bead blasting. Parts are bead blasted with glass beads which results in smooth, matte .The surface finishing process is the final step in CNC machining. Different techniques eliminate surface irregularities, improve part appearance, and add strength and resistance for increased functionality. The finishing technique you use depends on specific requirements, such as industry standards, the application of the part, and the materials you are working with. At Richconn, .CNC Machining Finishes CNC Surface Finish. Surface treatment involves modifying the surface of a substrate material to form a layer with distinct mechanical, physical, and chemical properties. The primary objective of surface treatment is to enhance the product’s corrosion resistance, wear resistance, aesthetic appeal, or other specialized .

The Role of CNC Machining in Achieving High-Gloss Finishes. Achieving a high-gloss finish in CNC machining involves more than just precision cutting. Here’s how CNC machining integrates with high-gloss polishing to deliver superior results: Starting with the Basics: Sanding and Smoothing. The path to a high-gloss finish begins with thorough .Xometry offers a wide selection of metal and plastic materials with various finishes and post-processing options. These high-performance materials are matched to an extensive list of manufacturing capabilities from CNC machining to sheet .The Importance of Surface Finish in CNC Machining. CNC machining is one of the many manufacturing processes that can produce a surface texture. By optimizing the process, the resulting texture can be usable without the need .

Finishing is the culminating step in CNC machining. This step has several roles in the quality of the final product. These include the removal of surface irregularities, enhancement of resistance, improvement of appearance, and addition of strength.What is CNC machining finishing and post-processing? Manufactured with automated speed and accuracy, CNC machined parts can be further customized with a variety of finishing and post processing options. Work with our expert engineers to select the right finishing option for your CNC machining project, including powder coating, bead blasting . Machining surface finish chart . Machining processes like grinding, milling, turning or drilling produce different surface roughness on a specific material after processing. Machine surface finish chart provides you with the comparison of average surface roughness produced by each machining process. CNC Machining . Surface finish calculator for reaming. Thread starter Mtndew; Start date Aug 6, 2015; Replies 38 Views 16,876 . it has been my experience reamer finish depends on. 1) sharpness of reamer 2) how much material is removed 3) coolant and or lubrication used 4) speed and feed of course but other 3 have a big effect .

how to put brackets on a metal gate

Surface finish or finish machining, a critical aspect of machining, delves into the fine details of perfecting a workpiece’s external quality and functionality. This precise process involves a meticulous surface adjustment, either by material removal or addition, to meet the highest standards of appearance and performance.Properties of Brass Suitable for CNC Machining. Understanding why brass is an excellent choice for CNC machining begins with an exploration of its key properties, which are the foundation of brass metalworking: The Influence of Lead: Brass’s composition, which includes lead, gives it exceptional machinability. Machinists benefit from high . Surface finish refers to the overall description of the surface, including surface texture, surface imperfections, Surface flaws, material add-ons and any coatings. . any coatings. Surface roughness measurement (Source&Credit:blum-novotest.com) Regarding manufacturing processes such as CNC machining and metal casting, manufacturers typically .

This article delves deeper into CNC machining Delrin, covering aspects such as Delrin material properties, applications of Delrin, the machining capacity of Delrin with CNC technology, surface finishes achievable for CNC machined parts in Delrin, and practical tips for successful Delrin CNC machining. First post here and relatively new to CNC machining. I've basically been dropped into a position where I have a lot of hot jobs and things to do/learn as I go due to unforeseen personnel issues. . the outside 16 finish should be no problem for a cnc lathe..the 8 finish on the other hand u might have to polish them or you can try burnishing .

A problem I have encountered with surface finish on aluminum is the result of chips being recut on the "following side" of the facemill. A method that has been used on conventional machines to minimize this occurance is to tilt the machine spindle head slightly "forward" so that the back side of the cutter doesn't touch the workpiece. Understanding Surface Finish in CNC Machining. The term surface finish refers to the overall characteristic and description of a surface, including any coating applied, dimension accuracy, texture, roughness, flaws, materials, flatness, waviness, and form. Simply put, surface finish defines the external topology (three-dimensional profile) of .

surface finish standards chart

surface finish by machining process

metal finishing specifications chart

Metal electrical boxes require screws with threads that can securely grip the metal surface, while non-metallic or plastic boxes may have specific screw requirements. Different types of electrical box screws include machine screws, self-tapping screws, wood screws, drywall screws, and anchor screws.

cnc machining finishes|machine finish symbols chart