cnc busbar copper processing machine At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our . Two Steel Metal brackets welded together. MetalsCut4U is known for the website where you can easily order a custom cut metal part in 4 easy steps. But at MetalsCut4U, you also have the possibility to send in your drawing, be it as CAD drawing or even a hand made sketch, and get a free quote from us.

0 · cnc bus bar machine

1 · busbar punching machine manufacturers

2 · bus bar bending machine

Measures 20-5/8 by 13-3/4" high by 9" deep. No Key. Box has been repainted. Vintage condition. Normal dents and dings. Paint loss. Felt is rough. Drawers work as they .

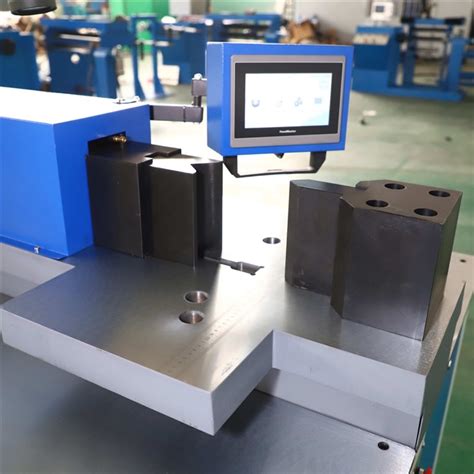

SunShine® 3 in 1 busbar machine adopts self-developed CNC control system and springback compensation technology, which can realize high-precision busbar processing .CNC Busbar Bending Machine is a high-efficiency, highly automated, and high-precision bus bar processing equipment used for bending copper and aluminum bus bars. This machine adopts .The MX-303SFBSSK CNC copper busbar processing machine is using for electrical industry to process copper or aluminum busbars. There are three working stations on the machine, each .At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our .

The 30-ton CNC (Computer Numerical Control) copper busbar bending machine is a cutting-edge solution tailored for precisely bending, cutting, and punching copper busbars.Powered by three separate hydraulic power packs. 1. CUT--Double column shear structure. The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet. 2. PUNCH--the united six-mode .The unique SLB 125 3-in-1 busbar center guarantees effortless cutting, punching and bending of copper busbars up to 125 x 13 mm (4" x 1/2"). Ideal for the switchgear work shop or at a site, the base unit transforms into a cutting, .JPSK-4A-303NC is a fully-automatic busbar processing machine. It can bend, cut, and punch copper and aluminum busbars. It has two plc touch screen for every processing unit.

Jingpeng: China professional manufacturers and suppliers of quality professional copper bus bar processing equipment for punching and shearing machine. You can source bulk Three in one busbar macihne with competitive price from our .The Boschert CU Profi copper bar processing machine is a powerful solution for efficient processing of copper, aluminum and steel bars. The CU Profi can be equipped with five to nine tool stations and accommodates bars up to 20-feet .SunShine® 3 in 1 busbar machine adopts self-developed CNC control system and springback compensation technology, which can realize high-precision busbar processing operations such as bending, cutting and punching.CNC Busbar Bending Machine is a high-efficiency, highly automated, and high-precision bus bar processing equipment used for bending copper and aluminum bus bars. This machine adopts a high-power, large-inertia servo motors and Siemens CNC system HMI, and cooperates with the CAD/CAM software system independently developed by our company.

cnc bus bar machine

The MX-303SFBSSK CNC copper busbar processing machine is using for electrical industry to process copper or aluminum busbars. There are three working stations on the machine, each station equipped with its own PLC and servo motor for precise and efficient control.

At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our proprietary software helps to reduce production time and minimize scrap.The 30-ton CNC (Computer Numerical Control) copper busbar bending machine is a cutting-edge solution tailored for precisely bending, cutting, and punching copper busbars.

Powered by three separate hydraulic power packs. 1. CUT--Double column shear structure. The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet. 2. PUNCH--the united six-mode turnplate in tooth shape.The unique SLB 125 3-in-1 busbar center guarantees effortless cutting, punching and bending of copper busbars up to 125 x 13 mm (4" x 1/2"). Ideal for the switchgear work shop or at a site, the base unit transforms into a cutting, punching or bending machine within seconds.JPSK-4A-303NC is a fully-automatic busbar processing machine. It can bend, cut, and punch copper and aluminum busbars. It has two plc touch screen for every processing unit.Jingpeng: China professional manufacturers and suppliers of quality professional copper bus bar processing equipment for punching and shearing machine. You can source bulk Three in one busbar macihne with competitive price from our factory.

busbar punching machine manufacturers

The Boschert CU Profi copper bar processing machine is a powerful solution for efficient processing of copper, aluminum and steel bars. The CU Profi can be equipped with five to nine tool stations and accommodates bars up to 20-feet in length, 9-inches wide and 1/2 -inch thick.

SunShine® 3 in 1 busbar machine adopts self-developed CNC control system and springback compensation technology, which can realize high-precision busbar processing operations such as bending, cutting and punching.CNC Busbar Bending Machine is a high-efficiency, highly automated, and high-precision bus bar processing equipment used for bending copper and aluminum bus bars. This machine adopts a high-power, large-inertia servo motors and Siemens CNC system HMI, and cooperates with the CAD/CAM software system independently developed by our company.

how to prevent oil canning in sheet metal

The MX-303SFBSSK CNC copper busbar processing machine is using for electrical industry to process copper or aluminum busbars. There are three working stations on the machine, each station equipped with its own PLC and servo motor for precise and efficient control.At EHRT, we provide businesses of all sizes with the latest in copper busbar, aluminum busbar and steel bar fabrication equipment. Our busbar punching machines and busbar bending machines feature precise tolerances while our proprietary software helps to reduce production time and minimize scrap.

The 30-ton CNC (Computer Numerical Control) copper busbar bending machine is a cutting-edge solution tailored for precisely bending, cutting, and punching copper busbars.Powered by three separate hydraulic power packs. 1. CUT--Double column shear structure. The shearing position adopts a double pillar structure with flat shears, no waste, no burrs, and no collapse feet. 2. PUNCH--the united six-mode turnplate in tooth shape.The unique SLB 125 3-in-1 busbar center guarantees effortless cutting, punching and bending of copper busbars up to 125 x 13 mm (4" x 1/2"). Ideal for the switchgear work shop or at a site, the base unit transforms into a cutting, punching or bending machine within seconds.

JPSK-4A-303NC is a fully-automatic busbar processing machine. It can bend, cut, and punch copper and aluminum busbars. It has two plc touch screen for every processing unit.Jingpeng: China professional manufacturers and suppliers of quality professional copper bus bar processing equipment for punching and shearing machine. You can source bulk Three in one busbar macihne with competitive price from our factory.

bus bar bending machine

Most sheet metal jobs are available directly through our local unions. SMART Job Bank listings usually reflect large projects, which will appear here when open positions are available.

cnc busbar copper processing machine|cnc bus bar machine