solidworks sheet metal enclosure part bom eci m1 I have a multibody sheet metal part inside an assembly, and a drawing which contains: A BOM, indented, With detailed numbering, detailed cut list checked. All sheet metal bodies in a .

Make use of filler metals that are thinner compared to slimmer metal sheets. Many welders use 0.024-inch and 0.023 inches for thinner metal sheets. Metals such as stainless steel feature a wire diameter of 0.034 and 0.030 inches.

0 · solidworks sheet metal property

1 · solidworks sheet metal bonding box

2 · solidworks sheet metal bill area

3 · solidworks sheet metal area

4 · solidworks indented bom diagram

5 · solidworks indented bom cut list

6 · solidworks bill of materials property

7 · solidworks bill of materials area

Yes, you can weld stainless steel with flux core using specialized stainless steel flux-cored wire designed for this purpose. This self-shielded wire eliminates the need for external shielding gas, allowing you to create strong, corrosion-resistant welds on stainless steel without using gas-shielded processes like TIG or MIG.

Maybe the question needs to go back further- as in, how to part data cards relate to creating an assembly? Then how does ECi M1 interpret those relationships to create a BOM .To insert a BOM saved with an assembly into a referenced drawing: Select Insert > Tables > Bill of Materials. In BOM Options, select Copy existing table. Select an assembly BOM from the .

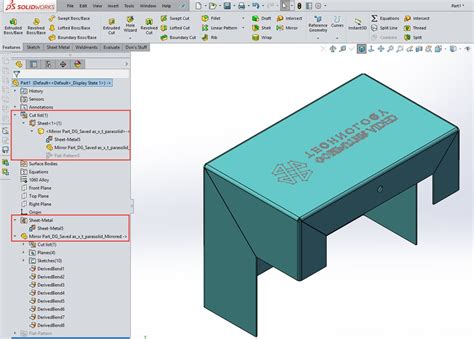

SOLIDWORKS Indented BOM with Single Body Sheet Metal Part. Article by Scott Durksen, CSWE updated March 13, 2018. When you create a SOLIDWORKS Indented BOM .Can sheet metal flat pattern info, specifically the flat pattern area, be shown in a SOLIDWORKS drawing bill of material? Yes, and it's easy to achieve. Real-time, direct, two-way link between your CAD and M1 ERP allows your engineers to compare, create, and update M1 ERP Item Master and BOM records right from the comfort of the CAD system of your choice. An .

I have a multibody sheet metal part inside an assembly, and a drawing which contains: A BOM, indented, With detailed numbering, detailed cut list checked. All sheet metal bodies in a .The sheet metal parts are all single bodies, but it appears as if the BOM is treating them as multibody with (blank?) cut lists. I can work around it by deleting or excluding the cut list but .

To insert a Bill of Materials into an assembly or part: Click Bill of Materials (Table toolbar), or Insert > Tables > Bill of Materials . Set the properties in the Bill of Materials PropertyManager, .

Whenever I try to export a BOM as an Excel 2007 spreadsheet, sheet metal parts always show up as assemblies with themselves listed as a sub-part (please see screen shot). Does anyone . Indented Bill of Materials. To use the Cut-List Property, you will need to first create an Indented Bill of Material. (Figure 3) Select Indented and the No numbering option. Figure 3. Indented Bill of Materials without numbering. .

solidworks sheet metal property

electric box iphone

They are tiles which have grout spacing between, and we will be waterjet cutting them from stone. The assembly has all the parts in place, and they are in the same plane, same thickness. I have found that converting a single part to sheet metal gives me a BOM cut list with Length, Width, area, blank area and cutting inner / outer linear inches.Before we place the BOM into the drawing we need to make sure we select the correct style of BOM to be used. For this we are going to pick the Indented No Numbering type. See Figure 2 below. Fig. 1 Sheet Metal assembly drawing .

I am trying to create an indented bill of materials for my assembly, but under each sheet metal part I get this additional child item called "sheet" with quantity "-". I don't want these to show up in the BOM, but the only way to get rid of them appears to be to click the option for "Parts Only", but this gets rid of the indented build plan . Raspberry Pi 4B Sheet metal Enclosure Complete Design.This video include Modelling of Base, Gromeet, decals. & Assembly of enclosure.Part 1 : https://youtu.b. we will learn Base flange, Edge Flange, Miter Flange, Sketched bend, Corner, hemming, Vent, flatten the parts, how to save as 2D drawing for autocad use, and.

Go start to finish creating an in-context sheet metal enclosure, making cut outs for parts, and creating a drawing of the part. When you're creating parts, i. Raspberry Pi 4B Sheet metal Enclosure Complete DesignPart 2 : https://youtu.be/tLUEC_yt_BAthis is how to design sheet metal enclosure for Raspberry pi 4b.all.

electric box knockout

We will need 7 sheets of material and produce 15 parts per sheet, except the last sheet with only 10 parts. Scrap estimation is 39.41%. If we make any changes to our component, sheet size, quantity, or offsets, we can quickly update our estimate. In this case, I’ve increased the width of the part and increased both the part and sheet offsets . I've toyed with the idea of creating a part template with a sheet metal body already present and excluded but that only works if I'm not creating a multi-body part. It might not seem like a problem but the size of our tables can mean hours of work removing "Sheet" rows if my colleagues or I forget to exclude as we go.

Suggestions . Is there a way to make sure I don't get a "Sheet" line in my BOM at a part level? EDIT: For the BOM settings I am using Indented and detailed cutlist. I use assemblies with both weldments and sheet metal parts. So its not like I can just use a top level BOM Catalog. View in SOLIDWORKS . ©2002-2024 Dassault Systemes SolidWorks Corporation .if I have an assembly contains sheet metal parts (each one is single body), when insreting BOM table, to get "Bounding Box Area" I have to select "indented" option, if I need to calculate total area for each thickness, I have to work on excel to move "indented" for ex. 1.1 to the main raw 1 and so on, and this is time consuming, is there is any .

This separation is typically negligible for any sheet metal part, but not for SOLIDWORKS. Figure 6 Figure 6a . 12 7) Avoid Self-Intersection with Edge-Flange As shown in (Figure 6a), one of the most typical situations for self-intersection is when applying an edge flange on a cut-extruded area. There are two basic approaches to avoid self-Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

I would like your opinion on sheet metal bodies in a multibody weldment part. Do you guys do that or do you create an assembly and pretend the parts are welded, when dealing with sheet metal parts. My current application involves a large sheet metal part with many bends accompanied by small welded plates for stronger tap locations. I’ve been looking into using the sheet metal tools as a way to cut out the redrawing step incorporating bend allowances, reliefs, mitres etc. earlier on in the design process. I’m having trouble converting this shelled part to a sheet metal one, I need to incorporate rips to the apertured face (see APERT.Open the part template you use the most and add those properties to it. It might be necessary to create a sheet metal feature to link, then delete it, but the property and it's value formula should remain. Save and close the template. Now, when you make a new part file, it should come pre-populated with those linked values, no more manual linking.

Keep your data accurate with ECi M1 CADLink and bidirectionally update your BOM data in one color-coded interface linking your CAD system and ECI M1. . With the Job BOM Integration, you can create parts on the fly and update existing jobs as soon as your changes are ready! . (SOLIDWORKS, AutoCAD, CREO, Altium, CATIA, etc.) and your M1 .Automated BOM Generation, export it as text and excel formats . Users of SolidWorks for Enclosure and Control Panel designs. www.egsindia.com 31 . equipment, the sheet metal parts were laser profiled directly from the flat patterns generated in SolidWorks. Creactive, enabled by SolidWorks, was able to complete Syspal's commission with great .Take your sheet metal skills to the next level by designing a sheet metal enclosure with SOLIDWORKS in this project-based course. Coursera Cuts Jobs Despite 0M Revenue Milestone View Close Class Central. . Adding graphics to parts; 6. Sheet Metal Drawings. Making assembly drawings; Adding part drawings; Creating flat patterns; Saving to .Looks good brother! One thing I'd note as someone in the metals industry is to take caution when putting holes or other features very close to bends (like the hole in the corner of part "Mini ISU Enclosure-3"); Depending on your sheet metal thickness, features may deform due to the metal stretching/contracting so your hole could get "pulled" towards the bend. Looks like you're .

If it was my rodeo, I would do bent sheet metal parts as separate parts (as those usually require bit more detailed drawings) and then just call the necessary dimensions in to the BOM - you could set up a template part that has all the necessary Custom Properties set up ready. You can dissolve the main assembly in BOM and only show the parts.

Step-by-step video tutorial showing how to make a small electrical enclosure from sheet metal. You will learn how to create a base flange, add edge flanges w.

Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of Sheet Metal Parts. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal .

Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .This hemisphere is part of this assembly. They cannot manufacture this hemisphere as a single piece, so they have decided to cut 36 smaller parts from a 10mm thick sheet metal, bend them to the desired radius, weld them, and thus assemble this hemisphere.

Designing an Electrical Enclosure using SolidWorks Sheet Metal.Please like & Subscribe to my channel.Also Support my channel https://www.buymeacoffee.com/D.

solidworks sheet metal bonding box

electric box hinges

$75.00

solidworks sheet metal enclosure part bom eci m1|solidworks indented bom cut list