cnc machine time cost The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator . A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

0 · machinery cost per hour calculator

1 · machine cost per hour calculator

2 · how to calculate cnc cost

3 · cnc machine shop hourly rates

4 · cnc machine price calculator

5 · cnc machine hourly rate calculator

6 · cnc machine hourly rate

7 · cnc hourly rate calculator

Basic Wiring Diagram: This diagram illustrates the standard wiring configuration of a terminal junction box, including the position of the incoming and outgoing wires, as well as the connections to various electrical devices or switches. Switch Circuit Diagram: This diagram focuses specifically on the connections related to a switch circuit.A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator .To calculate CNC machining cost per hour effectively, consider several key factors: .CNC machine pricing varies widely, typically ranging from ,000 to 0,000 or . Learn how CNC machining costs are calculated, including material types, batch sizes, machining time, and strategies to reduce expenses in your CNC projects.

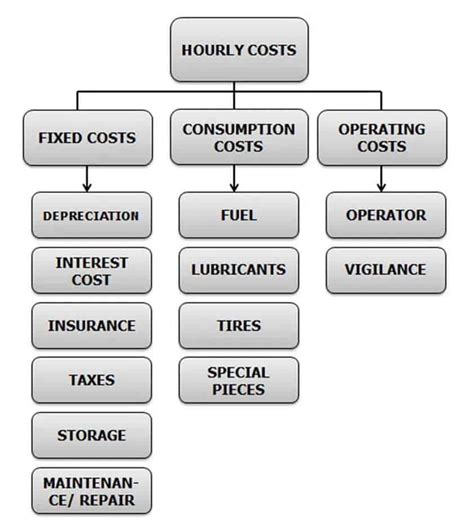

To calculate CNC machining cost per hour effectively, consider several key factors: machine depreciation, operator wages, overhead expenses, tooling costs, and material expenses. Start by determining the hourly rate of .

The cost of a CNC etcher will largely depend on the power of the laser installed on it as well as the size of the bed area. Entry-level CNC machines cost around 00, while . Here’s a quick video demo of the hourly rate calculator: Let’s go over each piece of data that must be entered: – Purchase Price: This is the . A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, the power and torque, number of axes, and .

The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner of machine cost. CNC Machines range from tiny in size (small enough to fit on a tabletop) .

Operational and Maintenance Costs: Owning a CNC machine is about more than just the initial purchase. Operational expenses, such as power consumption and recurring . According to industry reports, brand new CNC routers can range from ,000 to 0,000 depending on their specifications. The market for used CNC machines shows a broad spectrum of pricing, where well-maintained . CNC machine pricing varies widely, typically ranging from ,000 to 0,000 or more, depending on factors such as size, complexity, and capabilities. Entry-level desktop CNC machines suitable for hobbyists or small . The cycle time, which is the time spent in the actual machining of the component, can vary significantly based on the complexity of the part and the type of CNC machine used. Complex parts requiring detailed work will .

These are the broad factors that determine CNC Machine Cost. CNC Machine Size. The size of the machine, typically measured as the cnc machine’s work envelope (X, Y, and Z coordinate range), is a huge determiner .Even experienced machinists have crashes once in a while. Also if they’re paying by the hour they’ll be rushing. And if you’re helping them they’ll probably expect to only be charged while the machine is making chips. Find some jobs and you . The type of CNC machine used significantly impacts the cost of the machining process. Here’s a breakdown of typical costs for various CNC machines in China: 3-Axis CNC Milling. Cost Range: to per hour; Applications: Suitable for simpler geometries and 2.5D parts; CNC Turning. Average Cost: per hourEquipment – Cost Per Hour of Operation . a common formula : (machine purchase cost + expected lifetime maintenance cost) / expected hours of operating life. Direct Labor Cost per Hour . a common formula : (total annual labor costs + taxes + benefits + paid time off) / (total annual hours worked – breaks and training time)

By the time you get finished fully setting up, you are looking at a roughly 00 investment to properly run even the smallest capable machine - of which, the cost of the machine itself is maybe 00. . of which, the cost of the machine itself is maybe 00. Now compared to the cost of a "pro" machine (which start at k used and go way up .

machinery cost per hour calculator

machine cost per hour calculator

The cost of this complex equipment is higher than other types of CNC machines, more than 0,000 for an industry-sized machine. However, small ones are available for ,000 or around that. Additionally, DMG Mori (Germany) and Yamazaki Mazak (Japan) are two leading CNC compound machine manufacturer brands.

CNC Gcode Program for all the main controllers configured with dozens of parameters Ball Nose Surface Finish Get the surface finish based on the cutter’s diameter and the stepover.

The cost of a CNC milling machine depends on factors such as machine size, spindle power, and number of axes. Entry-level benchtop milling machines can range from ,000 to ,000, while large industrial-grade machines can cost several hundred thousand dollars.

CNC machines can cost hundreds of thousands of dollars, parts require hours to make so you can only produce so many in a day, and you waste a lot of material so you have to pay for a lot of raw material. And to program a piece into a machine for the first time can be annoying

Evaluate the trade-offs between material cost and machining time. Use materials efficiently, minimizing waste and optimizing nesting. 7. Keeping Internal Corner Radii Ratios Less Than 3:1 . When selecting a CNC machine for cost-efficiency, consider factors such as the machine's capabilities, precision, speed, and flexibility. Opt for machines . Machining Cost for CNC Machines (per part): Machining Time: 2 hours; Setup Time: 0.5 hours; Total Time: 2.5 hours; Cost for Time (2.5 hours * /hour): 5; . Factors Affecting CNC Machining Cost. Machine setup time: The time required to set up the CNC machine for a specific job can significantly impact costs. This includes tasks such as .CNC Machining needs good experience engineer to build product drawing with details including of dimensions, tolerance, raw material, surface treatment requirement etc., then have technique engineer to build machining program by MasterCam for operator to machine the custom parts with right CNC Machinery, the design set-up cost is one-time charge, hence 1pcs order means .Average Prices for CNC Machines. The cost of a new CNC can differ by the machine manufacturer and its country of origin. Here are the average price ranges for a few different types of CNC machines: How Much Is A CNC Router Machine? Entry-level CNC routers for hobbyists can cost as little as ,000 to ,000.

Tolerance – Tighter tolerances can increase the time required to achieve precision. Limitations. This CNC Estimator provides a rough estimate and may not account for all variables in a real-world CNC machining scenario. For accurate pricing, please consult with your CNC machining provider. Use Cases for This Calculator Estimating Material CostIn addition to the manufacturing time, the machine hourly rate is required. The machine hourly rate is a business parameter that indicates the costs for the use of a machine per hour. It is calculated by dividing the costs attributable to the .

We would like to show you a description here but the site won’t allow us. However, to provide a general idea, the cost of a typical CNC milling machine ranges from ,000 for basic versions to over 0,000 for more advanced models such as a 5-axis CNC machine. Remember, this is just the cost of the machine itself and doesn’t include operation, labor, maintenance, and material costs. 4-Axis CNC Machine. Saving a lot of time for machining prototype parts with complex structures. ,000 – 0,000. 5-Axis CNC Machine. . The data shows that increasing aluminum parts from 1 to 100 can save 84.27% of the cost without affecting CNC turning time. That’s because CNC turning is a fast process, so going from 1 to 100 doesn’t .

Learn how to consider six factors that affect your CNC machining project cost and time: material, design, machining, post-processing, quantity, and outsourcing.Mid-size CNC machines: like a vertical machining center or cnc lathe machine, typically range from ,000 to 0,000+. CNC routers : a bit more variability here, with costs usually falling between ,000 to ,000 . CNC machines are not cheap and they can cost you a lot based on the type, capabilities, and applications. Here is an idea of what different types of CNC machines are expected to cost in 2024. CNC Milling Machines: The prices for these machines start at around ,000 for entry-level units designed for small workshops or hobbyists. On the other .

The Maker Made M2 is the new and upgraded version of the original Maslow CNC. Modernized and upgraded for 2023, the Maker Made M2 still offers the fantastic 4 x 8 foot cutting range, as well as excellent 1mm accuracy, as well as a laser engraver upgrade kit.. For the extra money, you get an all-metal Z-axis, 40-inch cutting speed per minute, and built-in .The Langmuir Crossfire Pro CNC machine is a vital tool for industries including but not limited to automotive, aerospace, and manufacturing. . Initial investment cost; Langmuir Crossfire-Pro Competitors. Hypertherm Powermax; Lincoln Electric Torchmate; . "The initial setup took some time, but worth it for the results." .

Section 2: Key Factors Affecting CNC Machining Cost\ CNC machining costs are influenced by multiple variables. In this section, we will explore factors such as material selection, design complexity, part size, and tolerances. Each factor will be explained in detail, including its impact on machining time, tooling requirements, and overall cost.

How much does it cost to run a CNC? Someone told me to estimate per hour of running, which sounds crazy. I can handle the cost of a build, but it sounds like the cost of operation may deter me! . /hr. is probably a suggestion on how to value the machine time when charging other folks. That makes me feel a little better about the cost . The machine’s running time and the anticipated life of the tooling used in the machining process. For example, if a CNC machine has an estimated life of 10,000 hours and costs 0,000, the machine cost per hour would be .

how to calculate cnc cost

cnc machine shop hourly rates

In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to complete this task. We hope you enjoy this video. Thanks for watching and Have A Great.

cnc machine time cost|how to calculate cnc cost