sheet metal bending products This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Plastic junction boxes are lightweight, affordable, and resistant to corrosion. They are suitable for dry environments. Metal junction boxes are more durable, they are fire resistant and are used for wet or high-temperature areas. When To Use A Plastic Electric Box? Let’s review situations when you should use a plastic electrical box:

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

$99.00

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .

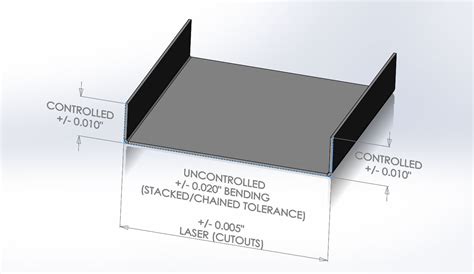

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.Sheet metal bending types and techniques, including press brake and metal bending processes. Learn about the different methods and applications in bending sheet metal fabrication for various manufacturing needs.

Choose from our selection of sheet metal benders, including over 50 products in a wide range of styles and sizes. In stock and ready to ship.Sheet Metal Benders. Make bends up to 135° in metal sheets. Benders have a clearance of 4" for insertion and removal of large workpieces such as vehicle panels and duct work. They attach .In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace. The best finishing. The best atomization for refinishing. (+1) 305-470-4513. Contact Us. What is sheet metal bending used for? Sheet metal bending is an essential process in the manufacturing of many products. It .

Industries That Use Sheet Metal Bending. The use of sheet metal bending is widespread, including: in the construction, automotive, transport, aerospace, and infrastructure industries. Sheet metal bending can be used in .Crest Bending Inc. is located in New Washington, Ohio, and a manufacturer of custom and customer designed tubing and sheet metal products. Skip to Content | Call Us Today: (419) 492-2108 | E-mail: [email protected]&B Sheet Metal Products . We specialize in heavy gauge, vented metal angle bending, available in steel up to 9 gauge, with the ability to provide custom punch holes where needed. Our capabilities extend to a wide range of metals, including stainless steel, galvanized steel, copper, aluminum, and many others in sheet and coil form. .

KAKA INDUSTRIAL W-3018 Sheet Metal Bending Brake 30-Inch Length Portable Metal Bender 0-90 Degrees Adjustable Steel Bender, 20 Gauge Mild Steel and 16 Gauge Aluminum Metal Bending 208 1.00 $ 111 . 00Sheet Metal Bending Price products found from trusted manufacturers & suppliers Product List Supplier List; Secured Trading; View: List View. Gallery View. 1 / 6. Favorites. Factory Price Flexible Panel Bender CNC Machine Sheet Metal Bending Machine US$ 80000-90000 .A Guide to Products Manufactured by Sheet Metal Bending. Sheet metal bending is a metal forming process in which a sheet metal workpiece is subjected to plastic deformation by applying force to the material and bending it at an angle. The bending process is typically performed using specialized machines called press brakes.JSTMT produces sheet metal cutting & bending Machine products, including Hydraulic & CNC Press Brake, Shearing Machine, Press Brake dies, Lathe, Ironworker, and Press Machine.It is used in sheet metal plate manufacturing, cutting, bending, stamping, and forming production lines. The sheet metal machines can provide a one-stop solution for our common & complex metal .

This Ironton 18in.W Sheet Metal Bending Brake is a sturdy, professional-quality bending brake that's ideal for bending heavy foils and light gauge metals or for forming acrylics and plastics. . Quality Used Products : Whole Foods Market America’s Healthiest Grocery Store: Woot! Deals and Shenanigans: Zappos Shoes & Clothing: Ring Smart Home .

Sheet metal bending is a process during which flat pieces obtain three-dimensional shape, such as sheet-metal housings, brackets, holders, and the like. . we have brought sheet metal bending to the highest possible quality level. View products made of sheet metal, for the forming of which the process of sheet metal bending was used, and the . Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When the sheet metal bend is aligned with the direction of the metal fibers, it is more likely to crack at the bend and have low bending strength, making it prone to breaking, as depicted in the accompanying figure. . Sheet Metal Bending Service. Craft precise angles with Prolean’s sheet metal bending services, specializing in metal bending tailored to your specific needs. Each final component or product undergoes rigorous quality control to ensure it meets the exact specifications and standards required. 1-135° bends; Standard accuracy ±1°

types of bending sheet metal

30. Drawing Sheet metal forming to make cup‑shaped, box‑shaped, or other complex‑curved, hollow‑shaped parts Sheet metal blank is positioned over die cavity and then punch pushes metal into opening Products: beverage cans, ammunition shells, automobile body panels Also known as deep drawing (to distinguish it from wire and bar drawing) ©2007 John .Hello everyone! You are watching video "Make A Simple Sheet Metal Bending Tool- DIY Projects"Learn how to create a simple sheet metal bending tool with this.

Polyurethane Products is capable of delivering solutions for SHEET METAL BENDING in Architectural Applications along with many more industrial needs. . Polyurethane Products is your one stop for the finest in Urethane performance and technology. Contact Us 31 West Industrial Dr Addison, IL, USA 60101 Phone: 800-772-7072 630-543-6700 .

The air die bending, which is used in the current study only, is a flexible die where the bending angle changes while the punch travels until the sheet metal angle becomes the same as that of the . Three-Station Edge Roller Bender,0-90° Bending Angle Bending Metal Roofing Materials,Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends in 29 to 22-Gauge Steel,Large Sheet Metal Bender 4.5 out of 5 stars 15 Sheet metal bending is a fabrication process where metal sheets are deformed along a straight axis to create specific angles and shapes without compromising the material’s integrity. . techniques are used to shape the .

This brake will bend sheet metal up to 36-inches wide. The maximum thickness is up to 16-ga. stainless steel or 12-ga. mild steel and aluminum. You will get the best results when bending smaller pieces of metal. When attempting to bend larger pieces of metal, the integrity of the bend deteriorates more quickly (you will end up with less crisp . The width, simplicity and set up was very good. Does a decent job in bending lightweight sheet metal with slight operating adjustments. This metal bender has been used to bend .023" thick diamond plate sheet metal into 3" x 3" x 48" L corner guards as well as lo12"W x 8'L metal panels. Mini Sheet Metal Brake: The maximum bending width of the box and pan brake is 48 inches / 1220 millimeters. Upgraded with a 0.31" thick blade and reinforced rib design, this product achieves excellent bending results, effortlessly accommodating 20-gauge low carbon steel and 14-gauge aluminum.

VEVOR Box and Pan Brake, 36-Inch, 0-130 Degrees Sheet Metal Bending Brake, . Drops, spills and cracked screens due to normal use covered for portable products and power surges covered from day one. Malfunctions covered after the manufacturer's warranty. Easy Claims Process: File a claim anytime online or by phone. Most claims approved within .HURRICANE 12 Inch Folding Tool, Sheet Metal Bending Tools for HVAC, Duct Bender Hand Tool, Forming Metal. 4.5 out of 5 stars. 718. 200+ bought in past month. .99 $ 17. 99. 10% off coupon applied Save 10% with coupon. . Shop products from small business brands sold in Amazon’s store. Discover more about the small businesses partnering . Explore sheet metal bending equipment and techniques. Learn step-by-step processes, bending sequences, and best practices for precision fabrication. . the blank cannot be placed. When bending semi-finished products that have been bent into a hook shape, a lower die with a relief groove should be used, as shown in Figure 7b. Figure 7 Bending . a) V-bend; b) U-bend; c) Z-bend; Related: V & U-shaped Bend Force Calculator (2) Press Bake Bending. Press brake bending is commonly used for the processing of sheet metal bending parts that are larger in size or not produced in large quantities. Press brakes can be divided into ordinary press brake and CNC press brake.. For sheet metal bending parts with .

This Ironton® 30in. Sheet Metal Bending Brake is easily portable from home to the jobsite. Ideal for bending mild steel, stainless steel, aluminum, copperplate, and other heavy foils and light gauge metals up to 30in. wide with the capability to make bends up to a full 90°.

sheet metal bending standards

large tool boxes metal

The bending stage is the most complex and critical stage in manufacturing sheet metal products. It is often this stage which produces a bottle neck in the whole process. In recent years, work in the area of automatic bending of sheet metal products has been accelerated with the introduction of bending robots (e.g..

Manual Hand Seamers Sheet Metal Tool: Ideal for bending, seaming and flattening sheet metal; Use as a sheet metal bender for HVAC projects ; Precision Seamer with Depth Marking: Features 1/4 inch depth marking on the blades for quick, precise bends; Optimized handle span for maximum power and comfort . In order to let our products reach more .

large modern metal house numbers

sheet metal bending near me

$6.00

sheet metal bending products|sheet metal bending chart