folding sheet metal at home The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Understand its nature and the forces that govern its formation. Apply consistent pressure . I had a service issue last night, and the chat I had via Twitter suggested that my cable boxes are old (they are) and that they should be replaced. I tried calling a local Spectrum store directly to confirm that they could do this for me, but that isn't possible as far as I could tell.

0 · homemade sheet metal tools

1 · homemade metal folding machine

2 · bending metal without a brake

3 · bending galvanized sheet metal

4 · bending aluminum sheet without brake

5 · bending 18 gauge sheet metal

6 · bending 16 gauge sheet metal

7 · bend sheet metal without brake

Forged metal tends to work. Even actual welding of the non-JB variety isn’t likely to work well in this case, goops and putties are a funny diversion but there’s just no chance.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools. .more.

Simple sheet metal bender using a hand roller, clamps and plywood.Music: Monkeys Spinning Monkeys by Kevin Macleod.

inventor sheet metal bend

Mastering the basics of sheet metal folding is essential for achieving high-quality, precise, and efficient results in your projects. You can enhance your manufacturing process by . The first commandment of sheet metal folding is to wholeheartedly embrace the fold. Understand its nature and the forces that govern its formation. Apply consistent pressure .Instead, a handy tool like a Bar Folder or Sheet Metal Folding Tool can help you produce precise bends of high quality right at home. Links To Purchase These Tools At End Of Article. Basic .You can do a lot with only a handful of tools. Even still, it can be pretty easy to mangle if you don’t use the right technique. Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working .

CAHAYA 2 in 1 Dual Use Extra Stable Reinforced Folding Sheet Music Stand & Desktop Book Stand Lightweight Portable Adjustable with Carrying Bag, Metal Music Stand with Music Sheet Clip Holder CY0204 4.6 out of 5 stars 12,728

homemade sheet metal tools

Buy Vekkia Sheet Music Stand-Metal Professional Portable Perforated Music Stand with Carrying Bag,Folding Adjustable Music Holder,Super Sturdy suitable for Instrumental Performance & Band & Travel: Musical Instruments - Amazon.com FREE DELIVERY possible on eligible purchases . bands, and home use. If you have any problems with the product, we .Sheet Metal Box: This is a great project to make if you are new to working with sheet metal. . Plus, they like that they've finally made something that they can use and take home. In this Instructable I'm going to walk you through how to .

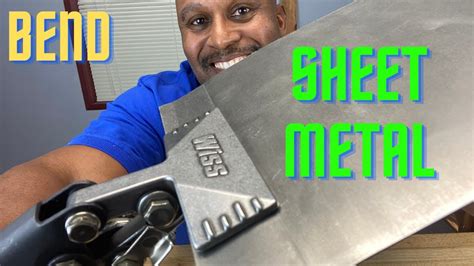

Bending Large Aluminium Sheet Without a Brake / Building a Car Roof Storage Pod / Box : We have a camper trailer that I mounted a roof pod on that I found on the side of the road in a verge side collection/“bring out your dead”. This soon proved to be indispensable and stores all our bulky gear – folding table and chairs, solar panel,. Wiss Sheet Metal Folding Tool - http://amzn.to/1T91GCePittsburgh Sheet Metal Folding Tool - http://amzn.to/1qYuh4x*As an Amazon Associate I earn from qualify.

18 Inch Metal Bender Hand Tool,Sheet Metal Folding Tool for Duct Bending,Metal Bending Tools,Yellow - Amazon.com. . #111,872 in Tools & Home Improvement (See Top 100 in Tools & Home Improvement) #80 in Rebar Cutters & Benders: Date First Available : October 25, 2023 : Warranty & Support .

Their aviation snips are the standard in the industry and there is probably no HVAC sheet metal duct maker (tin knocker) in the field that is without several WISS tools in their bag. This particular 24” folding tool is predominantly used, and was designed, for duct installer for in the field fabrication of 4-sided sheet metal duct ends.HVAC professionals use this folding tool on sheet metal to make hems, pans, end caps, and drive edges. Two folding depths; can fold up to 24 gauge steel and 28 gauge stainless steel, with helpful sights for accurate depth alignment. Also available in 12-Inch and 18-Inch lengths.

This U-shaped slider runs on a 20 x 20 mm square tube that is clamped down on the sheet metal piece at a distance 38 mm + the intended sheet metal flange in my case. As the angle grinder now slides on the pipe the only thing you have to do is to monitor the depth of the score that should be about half of the sheet thickness in this case.

Hi, First time using the sheet metal feature. I recreated my original part into a flat design (I would be interested in knowing if I could have unfolded my original design somehow, Unwrap gave nothing good). My part would be rolled around a 18mm cylinder. how can I fold/ roll it? I am unsure if Bend or Fold would achieve the shape I seek.The Crescent Wiss Straight Handle Hand Seamer is a powerful tool for bending or flattening sheet metal by hand. It utilizes an optimal handle span to deliver maximum power from an ergonomic operating range, and features non-slip cushion grips for superior comfort and control. . please get in touch with Home Depot Customer Service at 1-(800 .#artfullyrogue #makingalivingasamaker #metalartistIf you do metal work, at some point you will need to bend sheet metal. And if you're not ready to invest in.

28 gauge is extremely thin metal, you could easily form an angle by hand without any tools by just folding it over the edge of a table. Check out your local yellow pages for a sheet metal shop. At my shop we charge per cut, per brake. If you have cash, they have time. Just walk in and tell them what you want. On-Stage SM7222BB Tripod-Base Sheet Music Stand with Bag (Portable, Folding Sheet Music Setup, Adjustable Height and Angle, Heavy-Duty Tubular Legs, Nonslip Rubber Feet, Metal, Black) Music Stand for Sheet Foldable with Carrying Bag, New bee Metal Sheet Music Stand Portable, Adjustable Podium Stand with Tripod Base and Sheet Music Folder - .

ip rated junction box b and q

Without sheet metal folding, your product would never take the right shape. 4. What is the sheet metal folding process? Now you know how to fold sheet metal, let’s go through the sheet metal folding process in more detail. Sheet metal .Folding of sheet metal in forming technology, edge profiles and edge parts for a wide variety of industries - Mudersbach GmbH & Co. KG . English; Deutsch German de; English English en +49 2743 93359 0 . Home; Company. About .CIDAN Machinery Group is proud to be the world-wide industry leading source for sheet metal folders and metal bending machines. . and efficient ways to bend sheet metal into various forms. We provide high-performance, automated .12 Inch Sheet Metal Folding Tool - Ultimate HVAC Sheet Metal Bender, Hand Seamer, Metal Forming Tool for Duct Work & Metal Roofing; Premier Sheet Metal Folding Bar & Bending Tool for Professionals .99 $ 17 . 99

There are several metal folding techniques that can manipulate the shape of the material and create a variety of designs. . Home. 5 Metal Folding Techniques To Know . instead of the puncher pushing down the sheet metal to the right angle, this technique pushes them together completely. The metal will meet the bottom end of the v-opening die . Folding Tool Steel Metal Bending Tool Sheet Metal Bender for HVAC Metal Bending Forming 3/8" and 1" Fold Depths in Ductwork (18 Inch) . HURRICANE 18 Inch Folding Tool, Sheet Metal Bending Tool for HVAC, Bending . Home Services Experienced Pros Happiness Guarantee: Amazon Services Scalable Cloud Computing Services:

homemade metal folding machine

bending metal without a brake

Very rarely should fold be used. I've built hundreds and hundreds of sheet metal parts and maybe used fold 2 times. (and that wasn't even a sheet metal part but a folded over tail on a membrane switch model or something like that) ----- Sheet Metal Preparation. Select the appropriate sheet metal gauge and type for the project. Measure and mark the desired fold lines on the sheet metal. Wear gloves to protect hands from sharp edges while handling the metal sheets. Position the sheet metal on the machine’s bed, ensuring proper alignment with the fold line marks. Folding the . Hi all, I'm trying to model a sheet metal in Inventor Professional 2024 to the picture below, but find it impossible for a 0.5mm thick sheet metal to bend on a bent (at the four corners). It seems that the relief pattern due to intersecting bent may be too complex. Seeking advice and idea how I can approach this model.We have our conventional press brakes that will do all the usual things but we want to offer some distinctive options to benefit you – the best in precise and fast sheet metal folding. We’re proud to own the first Salvagnini P4 Panel Folder in New Zealand. This machine has completely changed the way we look at folding sheet metal parts.

inventor sheet metal flat pattern

Got some new tools but didn't want them to take up too much space so made this. It's made out of 5mm square profiles with 27x5mm pipes as axles. Just gonna fit the sheet metal folder underneath as some kind of fold-up thing with legs. Anyway, tested it out this week and works well for the 1mm sheet metal I'm working with for the cars I'm restoring. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation. The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update

bending galvanized sheet metal

With that in mind, a metal roof’s lifespan depends on the metal roof system. Properly installed with no maintenance, a steel screw down metal roof should last 20 years. With maintenance, it can last up to 30 years. On the other hand, a steel standing seam metal roof with a Kynar 500 painted finish should last 30 years and can even get up to 50.

folding sheet metal at home|bending metal without a brake