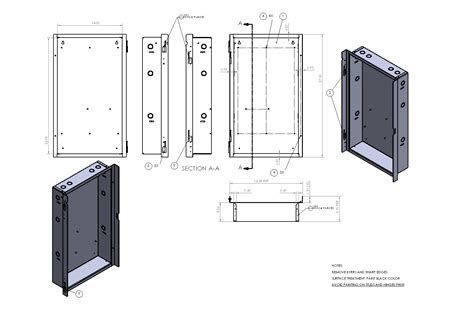

sheet metal structure design Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. Part (1) of Section 370-16 (a) describes in detail the method of counting wires, as well as clamps, fittings, or devices (i.e., switches, receptacles, combination devices) - by establishing an equivalent conductor-value for each. These values are .Learn how to properly wire a 3 way junction box with this step-by-step guide. Understand the necessary components and follow the correct wiring technique for safe and efficient electrical connections.

0 · sheet metal layout drawings

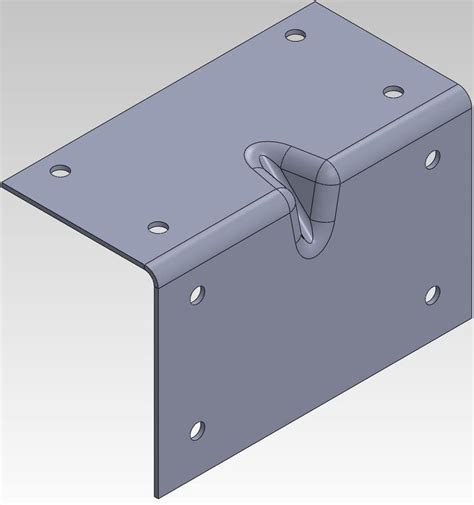

1 · sheet metal gusset design guidelines

2 · sheet metal fabrication design guide

3 · sheet metal design handbook pdf

4 · sheet metal design guidelines pdf

5 · sheet metal design calculations pdf

6 · sheet metal bending chart

7 · maximum thickness sheet metal bending

Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also se.

1. Why Steel will introduce you to the benefits that structural steel, and only structural steel, can bring to any building project. 2. Engineering Basics will show you how to create a structural layout for a building, with particular information about bay sizes, column sizes, and overall floor . Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending.The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, .

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Whether you’re a seasoned .

centro de mecanizado cnc argentina

The first step in creating a sheet metal part is sheet metal design. This process starts with an idea or concept that is then turned into a detailed 3D model using Computer-Aided Design (CAD) software. This 3D model includes . Principles of Structural Design for Sheet Metal Bending Parts | MachineMFG. Have you ever wondered why sheet metal parts crack or deform during bending? This article explores the essential principles of sheet metal .pushes into the sheet metal. The metal sheet is drawn into the die hole taking the shape of the cavity. 4) Shearing: In this operation cutting of sheets by shearing action. 1.3 Objectives 1. To study and perform structural analysis on sheet metal with . Sheet Metal Design:-. Sheet metal design is a specialized discipline within the realm of product design and engineering. It involves creating three-dimensional structures using thin, flat sheets of metal, often with complex .

Sheet Metal (SM) fabrication is perhaps one of the most common metalworking technique. Despite its prevalence, SM design is manual and costly, with rigorous practices that restrict the search space, yielding suboptimal results. In contrast, we present a .We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. . Whereas bending parallel to the rolling direction can lead to cracks because of destruction in grain structure. Bend Relief in Sheet Metal Bend. Design Considerations for Sheet Metal Hydroforming. Design plays a critical role in the success of sheet metal hydroforming. Engineers and manufacturers need to consider various factors during the design process to ensure optimal results. First, material selection is crucial, as different materials behave differently during hydroforming. 1. Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the correct material selection have an important impact on product cost, product performance, product quality, and processability.. Selection .

In today’s evolving engineering landscape, AutoCAD Mechanical has become a go-to tool for sheet metal design, providing a suite of powerful features that enhance productivity and precision. This blog will walk through the latest tools and features in AutoCAD Mechanical that streamline sheet metal design, offering engineers greater flexibility, efficiency, and .

The structural design of sheet metal equipment is closely related to the production process. With the improvement of the automation of sheet metal equipment, we need to constantly understand and contact new sheet metal knowledge, which provides a guarantee for better processing technology of designed parts in the future. In order to ensure the .

Sheet metal enclosures are protective or supportive structures fabricated from various metals to house, secure, or support electrical, electronic, or mechanical components. These enclosures play a critical role in numerous industries by protecting sensitive equipment from environmental factors, electromagnetic interference, and mechanical impacts. During the design phase, sheet metal design guidelines focus on the following 5 parameters. . Therefore, it is important to make sure the diameter of the hole is appropriate for the thickness of the sheet in order to maintain the structural integrity and long-term durability of the product. Localized Hardening. Sheet Metal Design Basics in 2021 – Complete List of Things That You Must Know. Blogs, Mechanical Products, Tutorials 0 comments 4659 Views Tuesday, May 11, 2021 Casing and enclosures made from Sheet Metals are used in a wide variety of applications. . We need to follow few guidelines while designing structures and shapes using sheet metals .Trabajos de presición en Chapa de metal con impresión 3D, presition 3D printing in metal sheet. 1350 E. Santa paula, CA 93060 [email protected] ( 805 ) 551-0220 ( 805 ) 551-0220 ESP . Innovation Sheet Metal Design has done some punching, forming and fabrication for us here at Titan. The quality of work has met our standards .

In order to ensure the safe and reliable operation of blade and sheet metal parts, it was necessary to design reasonable sheet metal structure and accurately predict the service life. In this paper, material mechanical property test of GH3536 was carried out to obtain its constitutive equation and fatigue performance parameters. The structure .

Automotive Structure Design. Automotive Structure Design | Manufacturing Processes. Sheet Metal Hydroforming: The Ultimate Guide for Engineers and Manufacturers. . Sheet metal forming is an essential manufacturing process that’s used in a wide range of industries. In sheet forming operations, a thin sheet blank is plastically deformed into . Sheet Metal Working, Design Guidelines for Sheet Metal Working.Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge 6 Sheet Stock Sizes and Gauge Lookup Chart 7 Stock Material Thickness Tolerances 8 Quoting Formats: 3D CAD and DXF Files

Structural. Much of the work SSM fabricates relies upon structural steel components to support it. . We can take your parts through all the phases of design: 3D modeling, engineering, fabrication, coating, assembly, package .

The fact that a sheet metal component derives its strength from geometry makes sheet metal design slightly trickier; however, once you start, you’ll quickly fall in love! Figure 1: Sample Sheet Metal Components. . When making a structure from sheet metal, fasteners will be required to complete assembly, or to allow components to be mounted. . A comprehensive learning guide and technical reference for FRC design using Onshape. Skip to content FRCDesign.org . Structure Fasteners Sheet Metal 3D Printing Tolerances Weight Saving . Sheet Metal. A guide on designing for sheet metal. Coming Soon. August 29, 2024 August 29, 2024.

The following are to links of sheet metal design resources, tools, articles and other useful data. Membership Services. Sheet Metal, Manufacturing, Design Equations and Calculations . Spring Design Apps Structural Shapes Threads & Torque Calcs Thermodynamics Physics Vibration Engineering Videos Design Manufacture Volume of Solids Calculators In this article, we delve into essential tips for sheet metal design, exploring techniques to minimize errors and optimize processes. From blanking to bending, each step is crucial for achieving precise, cost-effective results. . Additionally, some structures are improved in the design to simplify the springback angle, such as adding a . Request PDF | Generative Design of Sheet Metal Structures | Sheet Metal (SM) fabrication is perhaps one of the most common metalworking technique. Despite its prevalence, SM design is manual and .

Download scientific diagram | Structural model of a robot for sheet metal bending. (a) Structural design scheme 1. (b) Structural design scheme 2. (c) Design scheme of wrist structure. 1: Balance .

Generative Design of Sheet Metal Structures AMIR BARDA, Tel Aviv University, Israel GUY TEVET, Tel Aviv University, Israel ADRIANA SCHULZ, University of Washington, USA AMIT H. BERMANO, Tel Aviv University, Israel 1.45 kg 1.34 kg 3.03 kg 2.05 kg 2.68 kg 1.53 kg Fig. 1.

higher volumes, pressing sheet metal is often more cost-efficient, due to the speed and ability to automate the majority of the process. The definitions of bending and pressing can be seen in chapter 3.2. The method of pressing sheet metal also enables more complex geometries and thus makes it possible to eliminate welding of the components.

Introduction to Sheet Metal Processing Equipment 2 Combining 3D Printing and Sheet Metal Processing: Exploring Applications and Development Prospects 3 Introduction and comparison of laser cutting, waterjet cutting and plasma cutting 4 Design Points of Sheet Metal Structure—2 5 Design Points of Sheet Metal Structure—1 6 Process analysis of sheet metal structure design Yan yifan. 2022-04-25. Share. Facebook Twitter Pinterest LinkedIn Read Time: 1 Minute, 23 Second . Sheet metal processing is a comprehensive cold working process for sheet metal, including shearing, punching, cutting, folding, welding, riveting, etc. its remarkable feature is that the thickness .

sheet metal layout drawings

500/700 series white, 1 -gang 1-3/8in.depth device box. Small surface non-metallic raceway system is the ideal choice for a homeowner that wants to extend circuits or communication cabling in their home. Surface non-metallic raceway allows you to add fixtures and outlets without disturbing the drywall, plaster or insulation in your home.

sheet metal structure design|sheet metal bending chart