how to create lip in sheet metal boxes Watch for the flying clamp at 11:35. *warning, its loud when i start hammering* My attempt at showing how to make a channel in sheet metal using hand tools. This is something i taught. U.S. Precision has 9 dedicated welding rooms. We are Class A,B & C welding .

0 · strengthening lip sheet metal

1 · return lip on metal panel

2 · metal return lip

3 · metal forming return lip

4 · making a lip on sheet metal

$7,000.00

In this video I show you how to make a return lip on a panel so you can get a nice clean non sharp edge without expensive toolsIf you would like to support m.

Watch for the flying clamp at 11:35. *warning, its loud when i start hammering* My attempt at showing how to make a channel in sheet metal using hand tools. This is something i taught. I haven't been able to find info on how to make sheet metal rings or tubes with features in them. The .smp is what I was able to figure out to get a rolled ring. the .prt file I . I need to make a strengthening lip on the backside of this sheet metal part (to the height of the work plane) and I am not sure how to do this. I have tried lofted flanges, flange, contour roll, etc. (Pretty much any option .In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .

This design-and-make plan will enable you to make a small pan sheet metal folder that folds mild sheet metal from 18 to 26 gauge. With it, you’ll be able to fold “U” or “Z” sections or a lip on a sheet of metal.

The lip is built into the mating edge of the lid, and the groove is built into the edge of the box’s base. When you push them together, not only do they help to align the assembly, but they also help to seal it and keep it . Here’s how to make fascia trim with a hemmed bottom lip: Step 1: Align the outside edge of the coil with the rubber strip on the moving hinge—no need to measure. Lock the coil into place and pull the handles up as far as .

steel metal fabrication for sale

strengthening lip sheet metal

A step-by-step DIY tutorial on how to make metal farmhouse style shelf brackets with a lip from a flat steel bar. Wide open spaces, old wood planks resting in their metal braces, and vintage accessories..no doubt, the warm . One of the most effective ways to create bends in your sheet metal box without tools is the table edge method. This technique utilizes the straight edge of a sturdy table or . Learn how to convert a metal sheet into a drum with wonderful skills. Make a Box. Okay, so the first step is to make a box or container of some kind. The box will need to have two components—a base and a lid. . option will maintain the draft version when possible and extend the existing .

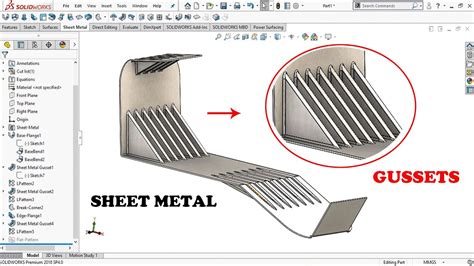

This is quick & simple tutorial for solidworks beginners starting working with sheet metal. DXF ready for metal fabricator shop!Follow simple steps to learn . This video shows a unique and EZ way to mark and cut out an electrical box hole in metal siding. My main tool for perfection????... LIPSTICK! That's.

Hi, I've been modelling up a sheet metal assembly and am rather inexperienced with inventor. I have searched online but couldn't find any specific information. I want to make a lid for this sheet metal compartment which is supposed to be the air pocket mounted inside the front of a car's chassis. The flat pattern of the box is given below. Use the last marks to draw a straight line across the width of the sheet metal. Cut the sheet metal along this line. Insert the end of the cut piece of metal marked at 1 inch into the lock-former machine. Turn the machine on. Open the clamp mechanism of your sheet-metal break and insert the end of the metal with the lock-form.

How to develop and fold sheet metal in Autodesk Inventor — SUPPORT THE CHANNEL —https://www.patreon.com/qualityhvacr?fan_landing=true— Check out @TruTech Tools, LTD —https://www.trutechtools.com (Use promo code “.

Learn how to make rounded bends with a sheet metal brake in this informative video tutorial. Make the box like a modified refrigerator and door, or like one would be like if the fridge was laying on it's side. Bend a 3/4" inside flange on the lid, with a 1/2" inside lip with hem for rigidity. Bend a 1" inside flange for the box, with a 1/2" outside lip with hem for rigidity and to shed water away from the box. In this SolidWorks Sheet metal tutorial you will learn how to model unfoldable box in SolidWorks by using Sketch bend command of sheet metal. SolidWorks 2016.

folding is a process that should be taken slow, hopefully I've provided sufficient photos to walk you through it. start close to a corner and fold towards you if using a vise. help the crease fold outward with a screwdriver and pliers. when you move to the next side stay close to your best looking corner and pinch the corner crease while folding towards you. repeat on all sides. when each .• Colored metal fence ideal for protecting and closing playgrounds. • Measures 200 x 72’5 x 8 cm. • Zinc-plated and baked steel with polyester paint. putting a 1-3" lip on sheet metal to form a tray Zach Gray. All Messages By This Member #54907 Folks: looking for some old-timey advice on a project I have. I am making a 74x36 drain pan out of either stainless or aluminum, something like the drain pans they put under washing machines, or an old-school oil drip tray that goes under machinery . In this video I will show you how to cut a metal raco box in to a sheet rock wall. I will show you how to use madison clips or F clips and how strong they ar.

How to make a simple Z Flash using a metal brake. This flashing is used above windows and other horizontal trim to prevent water intrusion. Creating sheet metal boxes involves a series of precise steps that ensure the final product is both functional and aesthetically pleasing. This guide will take you through the process of designing, cutting, and folding sheet metal to create durable and well-fitted boxes. Step 1: Planning and Design Tools and Materials: A Sheet Metal Box is a container crafted from thin, flat pieces of metal. These boxes can vary in size, shape, and material, depending on their intended use. They are known for their durability, flexibility, and cost-effectiveness, making them .

Machine designed to bend all four sides of a sheet metal box. Burr. A narrow flange turned on the circular section to be attached to the end of a cylinder. . A border of sheet metal that is bent over and used to strengthen the lips of sheet metal objects. Hand Seamer. Hand tool used for bending an edge or folding a seam in sheet metal. I thought this would be a great way to deal with a broken screw hole in an old work box similar to the attached picture. But when the G-Clip arrived, it was too wide to fit within the space between the two vertical ears. If you have a box similar to this, you'll have to resort to removing the box and replacing with a new one.Fastening features streamline creation of common features for plastic and sheet metal parts. We can create Lips and Grooves. Align, mate, and hold together t.

The sheet metal passes between the rollers, and the pressure shapes the desired bead profile. The bead roller uses a pair of complementary dies to roll a bead or rib into a sheet metal panel Shrinking and Stretching These two techniques used to change the surface area of sheet metal without significantly altering its thickness. Fabricating a sheet metal box can seem daunting, but with the right tools and techniques, it can be a straightforward process. In this article, we’ll go over the steps to fabricate a sheet metal box, including cutting, bending, and welding. Step 1: Designing the Box. Before you start fabricating your sheet metal box, you’ll need to design it. #artfullyrogue #makingalivingasamaker #metalartistIf you do metal work, at some point you will need to bend sheet metal. And if you're not ready to invest in. This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and order of operations to my students. .

steel lock box for swing gate

Lesco boxes create a wasted cavity/space around the electrical box that should be insulated on the outside wall and used for sound proofing when between interior walls. Electrical boxes and dead air spaces are high in the transmission of sound through the wall compared to other wall elements.

One of the most effective ways to create bends in your sheet metal box without tools is the table edge method. This technique utilizes the straight edge of a sturdy table or workbench. . To reinforce the corners without tools, you can create small folds or lips along the edges where two sides meet. This not only strengthens the box but also .

return lip on metal panel

steel lunch box india online

metal return lip

Search for used 3 axis cnc milling machines. Find Haas, Bridgeport, Kent, Clausing, Acra, GMC, and FPT for sale on Machinio.

how to create lip in sheet metal boxes|strengthening lip sheet metal