cnc machine wiki The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the . We distribute top-quality industrial tools and machine shop supplies at the best prices. View our collection of CNC machinist supplies and tooling packages. 714.897.1700 Chat Email 844.548.0100

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · computer numerically controlled machines

3 · cnc machines wikipedia

4 · cnc machine meaning in english

5 · cnc machine history

6 · cnc machine basic knowledge

7 · cnc machine acronym

As a medium size precision CNC machine shop, WBM provides contract machining services for anyone in the market. We specialize in custom product machining that requires CNC turning and CNC milling. WBM supplies a broad cross section of industries with both prototype and production machined parts.

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can .

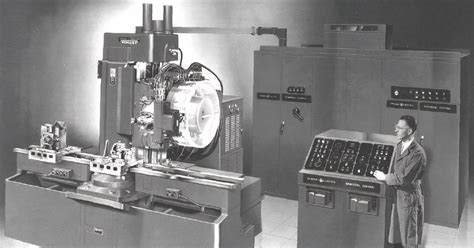

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer .A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions .

Learn the basics of CNC, CAM, NC code, and postprocessor for CNC controlled machines. Find out how to convert 3D and spline data for different types of CNC machines and axes.

Numerical control processing (CNC) refers to the use of numerical control equipment for machining by mechanical workers. This introductory article explains the main types of CNC machines, from CNC routers and milling machines, to less common types like Oxy-Fuel machines.

micu rear junction box honda odyssey

who invented the cnc machine

The failure mode, impact and criticality analysis (FMECA) is aimed at all possible failures of the product, and based on the analysis of the failure mode, determines the impact of each failure mode on the product’s work, finds out the single point of failure, and presses the severity of the failure mode The degree and its probability of occurrence determine its hazard.The Advantage Of Turn-Mill Machine. Compared with conventional Cnc Machining technology, the outstanding advantages of compound machining are mainly manifested in the following aspects.. Shorten the product .Five-axis linkage CNC machine tool is a high-tech, high-precision machine tool specially used for processing complex curved surfaces. This machine tool system is useful for a country’s aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment, etc. The industry has a decisive influence.Swiss Machine-the full name is the spindle-type CNC lathe, it can also be called the headstock mobile CNC automatic lathe, the economical turning-milling compound machine tool or the slitting lathe. It is a precision processing equipment that can complete lathe, milling, drilling, boring, tapping, engraving and other compound processing at one .

The worktable of the machine can move up and down, and the size has expanded the opening and closing height of the machine, making it more convenient to use. Double column hydraulic press This series of products are suitable for pressing, bending and shaping, embossing and creasing, flanging, punching and shallow drawing of small parts of . 2021-10-24 Cnc Machining Guide Comments Off on The working principle of the static pressure screw in the CNC machine tool feed system. 1. Working principle The ball screw nut pair is a transmission pair that puts balls between the screw and the nut, and the screw and the nut become a driving pair of rolling friction. .

The CNC cutting machine has the characteristics of fast cutting speed and small slitting during the cutting process. The design of the industrial master machine tool ensures the high speed and stability of the laser cutting process. It is equipped with fiber lasers of different powers, which can cut and perforate various metals and materials at .CNC machine tools are mainly used to process parts with complex shapes, but the structure of the fixtures used is often not complicated. The selection of fixtures for CNC milling machines can first be determined according to the batch size of the production parts. For single-piece, small-batch, and large-volume mold processing, positioning and .

The crank is the key part of the feeder’s transmission and feeding, and its strength and toughness are required to be high. In the previous production, the crank blank of the feeder was generally made of casting materials, which had the advantages of certain strength, good plasticity and toughness; however, due to the high price of castings and rough appearance, especially the .The development policy of my country’s CNC machine tools before the “Ninth Five-Year Plan” and 2010 is to focus on six types of mainframes: CNC lathes, machining centers, CNC grinders, CNC forging machine tools, CNC heavy-duty machine tools, and CNC precision electrical machine tools. Focus on breakthroughs in numerical control systems .

1. Long hole boring represented by the coaxial hole system of box parts is one of the most important contents in metal cutting. Although there are still examples of long hole boring with boring dies, guide sleeves, long boring bars supported by a bench-type milling and boring machine, or manual alignment of the workpiece by 180° rotation, in recent years, on the one .The high-power engraving machine can be used as a small-power engraving cnc machine. It is most suitable for large-scale cutting, embossing and carving. In the numerical control machine tool, the electric spindle usually adopts the frequency conversion speed regulation method. There are mainly three control modes: ordinary variable frequency .Uses: This CNC spinning machine is suitable for industries such as lamps, cookware, tableware, and handicrafts. Can complete barrel type, cone type, parabolic type, la; Batch production of horn type and warhead type products. Features: This CNC spinning machine is economical. Mainly for the products of copper, iron, aluminum, and stainless .

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. . Cnc Machine Wiki,Thanks!^^ tweet; Related Posts. Ultra-thin diamond film .Haas Automation, Inc is an American machine tool builder headquartered in Oxnard, California.The company designs and manufactures lower cost machine tools and specialized accessory tooling, mostly computer numerically controlled (CNC) equipment, such as vertical machining centers and horizontal machining centers, lathes/turning centers, and rotary tables . PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die .The vertical extruder, as the name suggests, is an extruder with a vertical feeding part. A solid step in the revitalization of China’s equipment manufacturing industry – the documentary of the world’s first 36,000-ton vertical metal extrusion machine independently developed. Xinhua News Agency, Beijing, July 27 (Xinhua News Agency reporter Zhang Yi) In midsummer, good news .

The CNC polishing machine servo constant pressure polishing, real-time compensation for consumables loss; the polishing disc is driven by an independent motor, and the positive and negative rotations are automatically switched to meet the needs of different processes; the CNC polishing machine is mainly used for mobile phones of non-metallic materials such as glass, .A CNC metalworking machine with a wood router attached to it, turning it into a makeshift CNC router. . A CNC wood router is a CNC router tool that creates objects from wood. CNC stands for computer numerical control. The CNC works on the Cartesian coordinate system (X, Y, . Numerical control machining programming is to compile a program list with instruction codes in accordance with the programming format according to the motion sequence of the processing parts, process parameters, workpiece size, direction of tool displacement, and other auxiliary actions (such as tool change, cooling, workpiece loading and unloading, etc.) .

3D Cnc Machine, also known as 3D Printer (3DP for short) is a process of Rapid Prototyping (RP), which uses layer-by-layer stacking to create a three-dimensional model. Its operation process is similar to that of a traditional printer. It’s just that traditional printers print ink on paper to form a two-dimensional plan drawing, while three .The CNC Machines (Computerized Numerical Control) are located in the Build Lab of Goldsmith and are managed and supported by the Technology Lab. Technology Lab equipment is only available to current students, faculty, and staff in the School of Architecture community. Use of the CNC Machines requires certification and a current Digital .A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece.This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] Milling covers a wide variety of different operations and machines, on scales from small individual .

For the main daily maintenance and maintenance of cnc machine tools, first select the appropriate use environment: the use environment of CNC lathes (such as temperature, humidity, vibration, power supply voltage, frequency and interference, etc.) will affect the normal operation of the machine tool, so When installing the machine tool, it .The repeatability of the slider of the CNC bending machine is ±0.0004 inches, and the precise angle of forming must use such precision and a good mold. The repeatability of the slider of the hand-controlled bending machine is ±0.002 inches, and the deviation of ±2~3° is generally generated under the condition of using a suitable mold. Coordinate system and direction of motion 1. The principle of determining the coordinate system. 1) The principle of the tool moving relative to the stationary workpiece This principle stipulates that regardless of whether the CNC machine tool is a tool movement or a workpiece movement, the program is written based on the tool’s trajectory during .Posted by: Chris Na 2021-05-26 Comments Off on CNC wire cutting technology and skills of CNC machine tools. Slow wire cutting machine tools are widely used and important. In the production and processing of plastic molds and precision multi-station progressive molds, they can ensure good dimensional accuracy, which directly affects the assembly .

micro precision machining manufacturer

when were cnc machines invented

michiana metal fabrication

computer numerically controlled machines

Explore & source all the CNC replacement parts you need to keep your machine in .

cnc machine wiki|cnc machine history