cnc lathe machine operating procedure 2.1 Properly secure the workpiece, start the lubricating oil pump first, and ensure that the oil pressure meets the machine’s specifications before starting. 2.2 When adjusting the gear box or hanging wheel, the power supply must be disconnected. After adjustment, all . See more Hubbell Wiring Device-Kellems provides Engineers and Designers with Hubbell Floor Box Receptacle resources, along with Recessed Electrical Floor Outlet specification designs. Hubbell Floor Boxes provide a uniform look throughout .

0 · turning operations on lathe machine

1 · turning operation lathe

2 · turning lathe diagram

3 · cnc turning lathe machine

4 · cnc lathe setup

5 · cnc lathe machine operations

6 · basic turning operations

7 · application of cnc lathe machine

CNC (Computer Numerical Control) programming is growing in popularity in the manufacturing industry due to its many applications. The ease of use provided by automated machine tools has made it easier than ever to manufacture parts for different uses.

stainless steel underbody truck box

1.1 Add appropriate lubricating oil and grease according to the machine lubrication chart. 1.2 Check that all electrical facilities, handles, transmission parts, guards, and limit devices are complete, reliable, and flexible. 1.3 All gears should be in the neutral position, and the belt tension should meet the requirements. 1.4 . See more2.1 Properly secure the workpiece, start the lubricating oil pump first, and ensure that the oil pressure meets the machine’s specifications before starting. 2.2 When adjusting the gear box or hanging wheel, the power supply must be disconnected. After adjustment, all . See more

4.1 Non-personnel are strictly prohibited from operating the machine. 4.2 It is strictly prohibited to touch the tools or any rotating parts of the machine during operation. 4.3 Use . See more3.1 Cut off the power and remove the workpiece. 3.2 Reset all handles to the zero position, and clean and tidy up the tools and equipment. . See more This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup . A lathe machine can finish machining operations fast and efficiently, especially when using automated procedures. A lathe machine can be an affordable way to produce .

stainless steel top box

From pre-operation inspections to precise shutdown protocols, it covers all the critical steps to ensure both safety and accuracy. By reading this, you’ll gain practical tips and a clear understanding of how to maintain your lathe, avoid common mistakes, and optimize your machining process. This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine. What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe. A lathe machine can finish machining operations fast and efficiently, especially when using automated procedures. A lathe machine can be an affordable way to produce custom parts in small-scale production.

Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool.ClickUp's CNC Lathe Machine SOP Template is designed to help you create and maintain standard operating procedures for CNC lathe machine operations. This Doc template contains all the necessary sections and content to guide your team through the .

Below, we explain CNC lathe machine operation. A lathe can be used for shaping metals, alloys, plastics, or even different types of wood. It’s based on moving unwanted material to shape a workpiece by using a stationary cutting tool around which the workpiece revolves. With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control. Start and home a CNC machine. Load tools into tool carousel. Set Tool Length Offsets. Set Part Offsets. Load a CNC program into the machine control. Safely run a new CNC program. Always be sure to follow the below best practices: Make sure the unit is fully powered down before beginning. You reduce the risk of accidents by ensuring the unit is off when loading the material. Firmly load and secure the part you are working on.

From pre-operation inspections to precise shutdown protocols, it covers all the critical steps to ensure both safety and accuracy. By reading this, you’ll gain practical tips and a clear understanding of how to maintain your lathe, avoid common mistakes, and optimize your machining process. This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine.

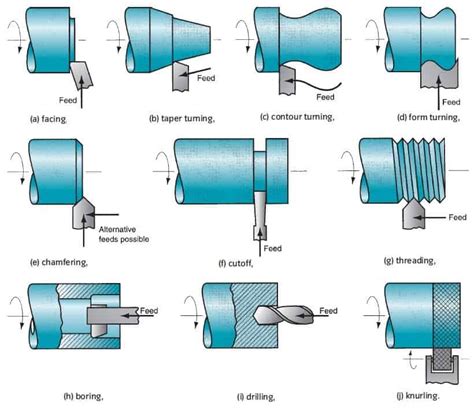

What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.

A lathe machine can finish machining operations fast and efficiently, especially when using automated procedures. A lathe machine can be an affordable way to produce custom parts in small-scale production. Though the CNC lathe machine’s operations are mechanical, it’s designed for automated precision machining. The primary CNC lathe machine operations are: Cutting involves separating large amounts of material from a workpiece with a sharp-edged cutting tool.ClickUp's CNC Lathe Machine SOP Template is designed to help you create and maintain standard operating procedures for CNC lathe machine operations. This Doc template contains all the necessary sections and content to guide your team through the . Below, we explain CNC lathe machine operation. A lathe can be used for shaping metals, alloys, plastics, or even different types of wood. It’s based on moving unwanted material to shape a workpiece by using a stationary cutting tool around which the workpiece revolves.

With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control. Start and home a CNC machine. Load tools into tool carousel. Set Tool Length Offsets. Set Part Offsets. Load a CNC program into the machine control. Safely run a new CNC program.

turning operations on lathe machine

turning operation lathe

turning lathe diagram

A junction box makes that easier by allowing you to connect directly to the main breaker. This negates the need to running wire through the entire house back to the breaker, providing that the power requirements of those .

cnc lathe machine operating procedure|cnc lathe setup