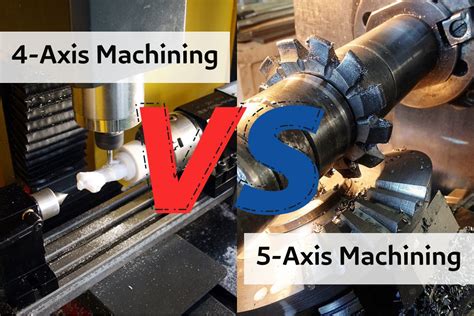

customized 3 axis 4axis 5axis cnc machining parts As advancements continue to shape this field, different CNC milling configurations have emerged, notably the 3-axis, 4-axis, and 5-axis machines. Each setup offers unique capabilities and is suitable for specific applications, depending on the complexity and intricacy of the part to be manufactured.

These meter box cables are often the culprit for bringing water into your electrical panel. When it rains, water penetrates the cables through tiny cracks and holes, and is funneled into your electrical panel where it can do all kinds of damage.

0 · 5 axis milling

1 · 4 axis milling vs 5 axle

2 · 4 axis cnc milling

3 · 4 axis cnc machine

4 · 3 axis machining vs 5 axle milling

5 · 3 axis cnc milling machine

Get the best deals on Disney Lunch Box In Collectible Metal Lunchboxes 1970-1979 when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your .

5 axis milling

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert . 4-axis CNC machining involves using a computer numerically controlled milling machine with four axes to create more complex parts than 3-axis CNC parts. A 4-axis milling machine can move the tool in four directions .Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . 4-axis CNC machining involves using a computer numerically controlled milling machine with four axes to create more complex parts than 3-axis CNC parts. A 4-axis milling machine can move the tool in four directions thanks to the movement of the fourth axis.

The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be. As advancements continue to shape this field, different CNC milling configurations have emerged, notably the 3-axis, 4-axis, and 5-axis machines. Each setup offers unique capabilities and is suitable for specific applications, depending on the complexity and intricacy of the part to be manufactured. In the case of large production batches, 3-axis CNC machining can offset the advantages of 4-axis and 5-axis CNC machining by employing custom quick fixtures, automated clamping methods, and other techniques to minimize setup time.

3-Axis milling, a critical component in CNC machining, represents a foundational technology in modern manufacturing. The X, Y, and Z axes are crossed by the cutting tool during 3-axis milling, which enables drilling, tapping, and other operations.We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.We offer 3-axis, 4-axis, and 5-axis horizontal machining centers that combine stability, precision, speed, and accuracy to deliver maximum productivity. Add our turn-key automation solutions and additional engineering services to maximize your production capacity . Choosing between 3-axis and 4-axis machining isn’t merely about counting axes; it’s about understanding the requirements of a project and aligning them with the capabilities of the machining method.

Here, we look at the differences between 3-axis, 4-axis and 5-axis machining and the types and advantages of their applicable parts.Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . 4-axis CNC machining involves using a computer numerically controlled milling machine with four axes to create more complex parts than 3-axis CNC parts. A 4-axis milling machine can move the tool in four directions thanks to the movement of the fourth axis.

The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be. As advancements continue to shape this field, different CNC milling configurations have emerged, notably the 3-axis, 4-axis, and 5-axis machines. Each setup offers unique capabilities and is suitable for specific applications, depending on the complexity and intricacy of the part to be manufactured.

In the case of large production batches, 3-axis CNC machining can offset the advantages of 4-axis and 5-axis CNC machining by employing custom quick fixtures, automated clamping methods, and other techniques to minimize setup time.

3-Axis milling, a critical component in CNC machining, represents a foundational technology in modern manufacturing. The X, Y, and Z axes are crossed by the cutting tool during 3-axis milling, which enables drilling, tapping, and other operations.

We support 3-axis, 4-axis, 5-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.

We offer 3-axis, 4-axis, and 5-axis horizontal machining centers that combine stability, precision, speed, and accuracy to deliver maximum productivity. Add our turn-key automation solutions and additional engineering services to maximize your production capacity . Choosing between 3-axis and 4-axis machining isn’t merely about counting axes; it’s about understanding the requirements of a project and aligning them with the capabilities of the machining method.

4 axis milling vs 5 axle

whisker box electrical

Washoe Metal Fabricating — Car and SUV Repair & Service in Sparks, NV CALL US: (775) 358-6390

customized 3 axis 4axis 5axis cnc machining parts|4 axis cnc machine