cnc laser cutting machine marking The technology of utilizing laser marking machines is advantageous compared to chemical etching or employing manual engraving in that it is safe. Key health and safety .

William Radtke Sheet Metal Ltd. 843 Guelph St. Kitchener, Ontario N2H 5Z2. Phone: 519-749-2790. Fax: 519-576-4263. Email:

[email protected]

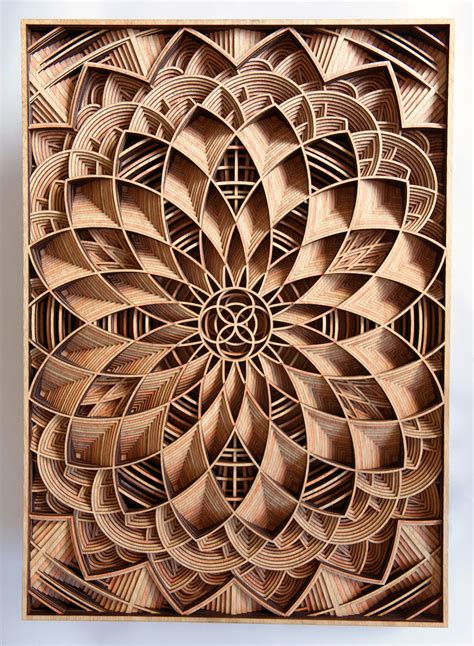

0 · lasercut works

1 · laser marking vs laser cutting

2 · laser cutting requirements

3 · laser cutting guide

4 · laser cutter how it works

5 · laser cutter drawing

6 · how to make laser cutter

7 · cnc co2 laser cutting machine

Wiley Metal Fabricating Inc is located at 816 W 34th St in Marion, Indiana 46953. Wiley Metal Fabricating Inc can be contacted via phone at (765) 671-7865 for pricing, hours and directions. Contact Info

Laser marking discolors the material’s surface, whereas laser etching and engraving remove a bit of the surface area as they mark. The primary distinction between laser etching and engraving is the depth the laser penetrates the . Laser marking machines have emerged as indispensable tools for a myriad of applications, ranging from product identification to engraving and coding. As we step into .Part marking, also known as direct part marking (DPM), is a secondary manufacturing process for adding logos, lettering or other customized designs to your custom CNC-machined parts. Two of the most common methods for part .Laser marking in CNC machining - what does it involve, and when is it used? Laser engraving is a process that removes material from a surface by vaporizing it using a laser beam. The laser works similarly to a chisel, drawing material and .

Lasers beams can mark by either cutting the material or discoloring it in a distinctive way that helps with identification. Common types of lasers include fiber, crystal, CO2 gas lasers and laser diodes. Common applications: Wood, .

The technology of utilizing laser marking machines is advantageous compared to chemical etching or employing manual engraving in that it is safe. Key health and safety .

Engraving, etching, and laser marking are different techniques of laser marking. Sometimes we use these terms interchangeably, but the methods are dissimilar. Laser engraving penetrates deeply into the material and leaves a cavity behind.

Having tested many of the best laser cutters and engravers, we created our recommendations for the best laser cutting machines in each price range, for each use, and more. I also link to some of my detailed hands-on reviews, such as for the Snapmaker 2.0 , Ortur Laser Master 3 , and more.Laser marking discolors the material’s surface, whereas laser etching and engraving remove a bit of the surface area as they mark. The primary distinction between laser etching and engraving is the depth the laser penetrates the surface.

Laser marking machines have emerged as indispensable tools for a myriad of applications, ranging from product identification to engraving and coding. As we step into 2024, it becomes crucial for businesses and manufacturers to stay abreast of the latest advancements in laser marking technology.Part marking, also known as direct part marking (DPM), is a secondary manufacturing process for adding logos, lettering or other customized designs to your custom CNC-machined parts. Two of the most common methods for part marking are laser engraving and silk screening.

Laser marking in CNC machining - what does it involve, and when is it used? Laser engraving is a process that removes material from a surface by vaporizing it using a laser beam. The laser works similarly to a chisel, drawing material and creating permanent, deep marks.

Lasers beams can mark by either cutting the material or discoloring it in a distinctive way that helps with identification. Common types of lasers include fiber, crystal, CO2 gas lasers and laser diodes. Common applications: Wood, leather, plastic, glass. Pros: Cons: Label Printing. The technology of utilizing laser marking machines is advantageous compared to chemical etching or employing manual engraving in that it is safe. Key health and safety benefits include: Reduced Chemical Exposure: Laser marking, on the other hand, is a dry process which basically frees the etching process from dangerous chemicals and solvents. Whether you're in manufacturing, crafting, or prototyping, understanding how to operate a CNC laser cutter is essential. This comprehensive guide will walk you through the entire process, from initial setup to advanced techniques, ensuring you can harness the full potential of this powerful machine. Understanding CNC Laser Cutters

The two most common ways to engrave metal parts are laser engraving, and CNC engraving. The same general principles apply, but they are two different machines, and mark the parts differently. In some cases, laser engraving is better, and other times CNC engraving is best. Engraving, etching, and laser marking are different techniques of laser marking. Sometimes we use these terms interchangeably, but the methods are dissimilar. Laser engraving penetrates deeply into the material and leaves a cavity behind. Having tested many of the best laser cutters and engravers, we created our recommendations for the best laser cutting machines in each price range, for each use, and more. I also link to some of my detailed hands-on reviews, such as for the Snapmaker 2.0 , Ortur Laser Master 3 , and more.

Laser marking discolors the material’s surface, whereas laser etching and engraving remove a bit of the surface area as they mark. The primary distinction between laser etching and engraving is the depth the laser penetrates the surface. Laser marking machines have emerged as indispensable tools for a myriad of applications, ranging from product identification to engraving and coding. As we step into 2024, it becomes crucial for businesses and manufacturers to stay abreast of the latest advancements in laser marking technology.Part marking, also known as direct part marking (DPM), is a secondary manufacturing process for adding logos, lettering or other customized designs to your custom CNC-machined parts. Two of the most common methods for part marking are laser engraving and silk screening.Laser marking in CNC machining - what does it involve, and when is it used? Laser engraving is a process that removes material from a surface by vaporizing it using a laser beam. The laser works similarly to a chisel, drawing material and creating permanent, deep marks.

Lasers beams can mark by either cutting the material or discoloring it in a distinctive way that helps with identification. Common types of lasers include fiber, crystal, CO2 gas lasers and laser diodes. Common applications: Wood, leather, plastic, glass. Pros: Cons: Label Printing. The technology of utilizing laser marking machines is advantageous compared to chemical etching or employing manual engraving in that it is safe. Key health and safety benefits include: Reduced Chemical Exposure: Laser marking, on the other hand, is a dry process which basically frees the etching process from dangerous chemicals and solvents. Whether you're in manufacturing, crafting, or prototyping, understanding how to operate a CNC laser cutter is essential. This comprehensive guide will walk you through the entire process, from initial setup to advanced techniques, ensuring you can harness the full potential of this powerful machine. Understanding CNC Laser Cutters

were is distribution box on 07 saturn acur

Fix Sagging Futons has a mattress that’s separate from the frame, consider using a pillow under the spot that’s starting to fold. A firm bed pillow can provide the much-needed support to fix a sagging futon for a while.

cnc laser cutting machine marking|laser cutting requirements