axis designation of cnc machine In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . Underground electrical wiring is, quite literally, electrical wiring that’s buried beneath the ground. This isn’t just a game of hide and seek with wires; it’s a strategic move. By placing electrical cables underground, we .

0 · cnc with rotary axis

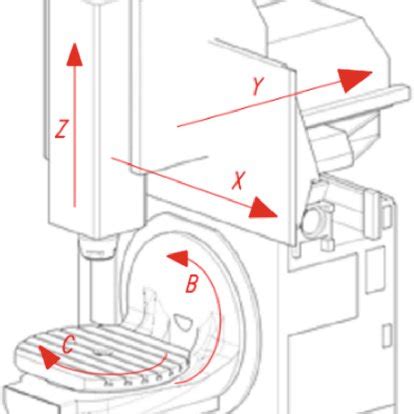

1 · cnc machine axis locations diagram

2 · cnc machine axis direction

3 · cnc axis explained

4 · cnc axis chart

5 · axis identification in cnc machine

6 · 4 axis cnc milling machines

7 · 4 axis cnc machine cost

Whether you’re frying or searing, an undercabinet hood from Lowe’s can help you breathe easy and eliminate harsh odors from your home. Before you shop, determine if you need a ducted undercabinet range hood or a ductless undercabinet range .

CONSIDERED AN AXIS ONLY WHEN CONTROLLED FROM TAPE / CD INSTRUCTIONS AND HAVING OPEN LOOP OR CLOSED LOOP DRIVE. MOTIONS OF NC M/T IN X,Y AND Z .

thin sheet metal parts

Understanding the axis designation of CNC machines is fundamental to effectively operate and program them. It allows machinists and operators to visualize how the machine moves, plan .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the .

cnc with rotary axis

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis.Identify the programmable axes on a CNC machining. Cartesian coordinates allow one to specify the location of a point in the plane, or in three-dimensional space.

Understanding axes and their operations can unlock the potential of CNC machines. 3-axis machines are sufficient for simple parts and mass production. Adding rotational axes (A,B,C) . Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even . There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

cnc machine axis locations diagram

cnc machine axis direction

CONSIDERED AN AXIS ONLY WHEN CONTROLLED FROM TAPE / CD INSTRUCTIONS AND HAVING OPEN LOOP OR CLOSED LOOP DRIVE. MOTIONS OF NC M/T IN X,Y AND Z DIRECTIONS HAVE BEEN STANDARDIZED AND ARE FOLLOWED BY MANUFACTURERS. IT IS THE RELATIVE MOTION OF THE CUTTING TOOL W.R.T. THE W/P THAT DETERMINES .

Understanding the axis designation of CNC machines is fundamental to effectively operate and program them. It allows machinists and operators to visualize how the machine moves, plan tool paths, and optimize the manufacturing process.

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary . Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis.Identify the programmable axes on a CNC machining. Cartesian coordinates allow one to specify the location of a point in the plane, or in three-dimensional space.Understanding axes and their operations can unlock the potential of CNC machines. 3-axis machines are sufficient for simple parts and mass production. Adding rotational axes (A,B,C) lets the CNC machine make more complex parts,adding value to the production line.

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes. There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool along the length of the workpiece.

In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.CONSIDERED AN AXIS ONLY WHEN CONTROLLED FROM TAPE / CD INSTRUCTIONS AND HAVING OPEN LOOP OR CLOSED LOOP DRIVE. MOTIONS OF NC M/T IN X,Y AND Z DIRECTIONS HAVE BEEN STANDARDIZED AND ARE FOLLOWED BY MANUFACTURERS. IT IS THE RELATIVE MOTION OF THE CUTTING TOOL W.R.T. THE W/P THAT DETERMINES .

Understanding the axis designation of CNC machines is fundamental to effectively operate and program them. It allows machinists and operators to visualize how the machine moves, plan tool paths, and optimize the manufacturing process.CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the role and significance of the X, Y, Z, and additional axes, as well as the potential of multi-axis and specialized machines, you now possess the knowledge necessary .

Place your hand in front of your CNC machine, aligned with the machine’s spindle, and you’ll see the axes line up perfectly. The thumb is the X-axis. The index finger is the Y-axis.

cnc axis explained

Identify the programmable axes on a CNC machining. Cartesian coordinates allow one to specify the location of a point in the plane, or in three-dimensional space.Understanding axes and their operations can unlock the potential of CNC machines. 3-axis machines are sufficient for simple parts and mass production. Adding rotational axes (A,B,C) lets the CNC machine make more complex parts,adding value to the production line. Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes.

cnc axis chart

Optimize your storage with Seville Classics UltraHD Storage Cabinet. This unit is designed to optimize smaller spaces with a footprint of 24" wide by 18" deep by 66” high. The door is constructed of commercial grade steel with recessed handle. The door features UltraGuard fingerprint-resistant coating which helps resist smudges and fingerprints.

axis designation of cnc machine|4 axis cnc milling machines