edge bending sheet metal When bending a workpiece, it will naturally spring back a little after the load is lifted. Therefore, it has to be compensated for when bending. The . See more Whether you’re a seasoned professional or a hobbyist, discovering the right used 10 ft sheet metal brake can elevate your work and save you money in the process. Let’s dive .

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Search for used bridgeport mill. Find Bridgeport, Acer, and Precision Matthews for sale on Machinio.

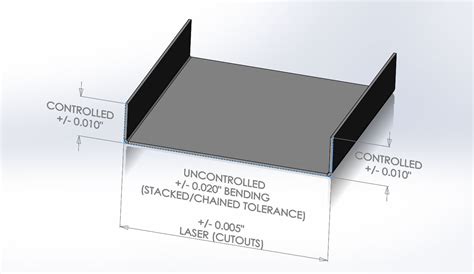

There are quite a few different bending methods available. Each has its own advantages. The dilemma is usually between going for accuracy or simplicity, while the latter gets more usage. Simpler methods are more flexible and most importantly, need fewer different tools for getting a result. See moreWhen bending a workpiece, it will naturally spring back a little after the load is lifted. Therefore, it has to be compensated for when bending. The . See moreIf you design your bent sheet metal parts in CAD softwarethat has a special sheet metal environment, use it. It exists for a reason. When . See moreFractory offers the aforementioned possibilities on a web-based platform. Getting an online bending quoteis very easy, you just have to upload your 3D files (STEP, SLDPRT, IPT) onto our platform and the price and lead time will be displayed on your . See more

So, I talked to our experienced sales engineer who knows his bit about sheet metal bending. He lit up and decided to make the fullest of the opportunity to share his insights on sheet metal bending. Thus, he brought out a list of common mistakes and the solutions to . See more

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .Edge bending is another very common sheet metal process and is performed with a wiping die. Edge bending gives a good mechanical advantage when forming a bend. However, angles greater than 90 degrees will require more complex .

Bottom bending, also known as die bending or edge bending, is a technique where the metal sheet is pressed against a die to bend it around a bend line. The punch descends fully into the die, making contact with the . Wipe bending or edge bending, is another way to bend sheet metal edges. It is important to make sure that the sheet is properly pushed onto the wipe die. As a result, the wipe die also determines the bend’s inner radius. The slack between the wipe die and the punch plays an important role in getting a good result. Rotary Bending

types of bending sheet metal

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.Edge bending is another very common sheet metal process and is performed with a wiping die. Edge bending gives a good mechanical advantage when forming a bend. However, angles greater than 90 degrees will require more complex equipment, capable of .

Bottom bending, also known as die bending or edge bending, is a technique where the metal sheet is pressed against a die to bend it around a bend line. The punch descends fully into the die, making contact with the bottom, and applies force .

When bending a beveled edge, inadequate bending height is the main cause of bend distortion. As depicted in the accompanying figure, in the original design, the bending height on the left is too small, which increases the likelihood of bend deformation and reduces the overall bending quality.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Have you ever wondered how thin sheets of metal are bent into precise shapes? This article explores the fascinating world of L, U, and Z bending techniques in sheet metal fabrication. You’ll learn the key factors, formulas, and practical tips to achieve perfect bends every time. 1) Factors determining the minimum L bending.Edge bending is used to eliminate sharp edges, to provide geometric surfaces for purposes such as joining, protecting the part, increasing stiffness, and for cosmetic appearance. Flanging is bonding and forming technology used in sheet-metal forming.The minimum distance between hole/slot edge to bend edge avoid metal distortion, deformation, and fracturing. The recommended minimum distance between hole /slot edge to bend in sheet metal parts is three times the sheet thickness plus bend radius.

Wipe bending or edge bending, is another way to bend sheet metal edges. It is important to make sure that the sheet is properly pushed onto the wipe die. As a result, the wipe die also determines the bend’s inner radius. The slack between the wipe die and the punch plays an important role in getting a good result. Rotary BendingThis Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.Edge bending is another very common sheet metal process and is performed with a wiping die. Edge bending gives a good mechanical advantage when forming a bend. However, angles greater than 90 degrees will require more complex equipment, capable of .

Bottom bending, also known as die bending or edge bending, is a technique where the metal sheet is pressed against a die to bend it around a bend line. The punch descends fully into the die, making contact with the bottom, and applies force . When bending a beveled edge, inadequate bending height is the main cause of bend distortion. As depicted in the accompanying figure, in the original design, the bending height on the left is too small, which increases the likelihood of bend deformation and reduces the overall bending quality.Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Have you ever wondered how thin sheets of metal are bent into precise shapes? This article explores the fascinating world of L, U, and Z bending techniques in sheet metal fabrication. You’ll learn the key factors, formulas, and practical tips to achieve perfect bends every time. 1) Factors determining the minimum L bending.

Edge bending is used to eliminate sharp edges, to provide geometric surfaces for purposes such as joining, protecting the part, increasing stiffness, and for cosmetic appearance. Flanging is bonding and forming technology used in sheet-metal forming.

cnc busbar processing machine

cnc busbar shearing punching machine

$100K+

edge bending sheet metal|problems with sheet metal bending