stick welding aluminum sheet metal Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted . In our Welding and Metal Fabrication program, youll learn how to read blueprints and plan and implement the welding and fabrication processes. That includes cutting and layout, fitting and fabrication, and common welding processes that bring all the pieces together, such as shielded metal arc, flux-cored arc, and gas metal arc.Best Metal Fabricators in Nashville, TN - Steel Beautiful Welding and Fabrication, Duck Welding Sales & Service, Herendon Iron Work, Modern Iron Concepts, Iconic Metal .

0 · welding thin metal with stick

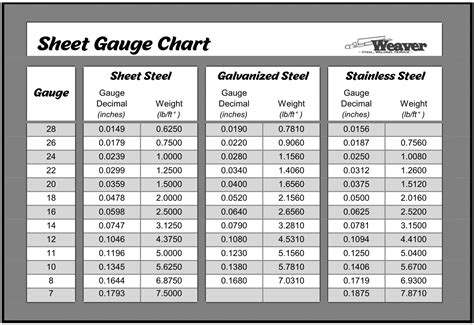

1 · welding 24 gauge sheet metal

2 · welding 22 gauge sheet metal

3 · welding 16 gauge sheet metal

4 · welding 14 gauge sheet metal

5 · tig welding thin sheet metal

6 · mig welding sheet metal basics

7 · arc welding automotive sheet metal

Steel Stud Device Box, Gangable, 2-1/2 in. Deep, 16 Cu. In., with MSB Metal Stud Bracket, 2-3/8 & 3-5/8 in. Stud Sizes, Raised ground screw, with Concentric, 1/2 & 3/4 in., and 1/2 in. KO (25-Pack). Plaster ears allow box to be used in rework applications

Many issues with welding aluminuminvolve its high thermal conductivity and low melting point. Add the problems presented by the chemical composition, and we have numerous issues unique to aluminum that must be addressed. See moreFor a quick repair out in the field, stick weldingcan be a simple, fast method to get the job done. But it is not the “best” way to weld aluminum. MIG and TIG welders produce better . See more

Stick welding aluminum follows most of the basic stick welding “rules.” But there are some points unique to stick welding aluminum, and they are worth reviewing. See more Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

For metal smaller than 1/8", stick welding using aluminum welding rods is typically not advised. The fact that aluminum is often supplied in thin sheets may cause problems. However, let's say you don't have access to a . When welding aluminum with a stick (or shielded metal arc welding), selecting an appropriate stick welder is crucial. For stick welding aluminum, an AC TIG welder makes sense due to aluminum’s high thermal conductivity and the presence of the aluminum oxide layer.

Discover the steps for successful stick welding of aluminum with this complete guide. Learn about the materials, processes, and safety tips you'll need to get started! 10 Simple Step-by-step Guidelines on How to Weld Aluminium With a Stick Welder Step 1: Prepare the Workpiece. The first step to successful stick welding with aluminium is proper preparation. Begin by cleaning the metal .

Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs . and considerable strength. Also, it’s compatible with different welding processes, including MIG, TIG, and stick welding. Aluminum’s lightweight and corrosion resistance makes it valuable for .

Welding Kit 12Pack 6061 T651 Small Aluminum Sheet Metal 2" X 2" X 0.125Inch Flat Plain 3MM Aluminum Plate Weld Practice kit for MIG, TIG, Stick, Arc, Gas, Brazing, Welding Practice Kit for Beginners - Amazon.com Hello, I'm confused about 6013 rods for sheet metal. I've read on the packaging that 6013's are low penetration rods and are used for sheet metal. I've tried welding 22 gauge and unless I'm doing a quick 1 sec. tack the rest of . The E6013 welding rod is the best to stick weld thin mild steel and is known as a sheet metal rod. An E6013 has a flux covering with high amounts of rutile. Rutile creates the smoothest arc with light penetration that won’t burn through the joint as easily as other rods. Can you stick weld thin aluminum? Stick welding thin aluminum is exceptionally hard because this process creates a strong arc that tends to blow through thin metals. Thin aluminum saturates with heat very fast and with a low melting point is easy to melt. With enough practice, you can weld thicknesses of 1/8″, 3/32″, or slightly less.

However, stick welders can also be used to weld sheet metals if the welding practices are right. Q: When it comes to welding wires, what welding rods are most suited for welding sheet metal? A: Thinner rods such as the 6010 or .

ira distribution box 7 code 2

welding thin metal with stick

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).We have introduced multiple welding equipment and experienced metal welders to provide our customers with low-cost, high-efficiency, and small-deformation welding techniques, suitable for all-round welding of thin plates, medium-thick plates, and even thick plates. According to your needs and drawings, choose the welding process that suits you.

When welding aluminum with a stick (or shielded metal arc welding), selecting an appropriate stick welder is crucial.For stick welding aluminum, an AC TIG welder makes sense due to aluminum’s high thermal conductivity and the presence of the aluminum oxide layer. The PRIMEWELD TIG 225X is a formidable welding machine for sheet metal work. Its dual TIG/Stick welding capability allows it to easily handle different welding tasks. The precise control over amperage, ranging from 10-225A, allows for very fine work on sheet metal, maintaining the integrity of the material.While MIG and TIG welding is recommended for thin metal welding over stick welding, it is still possible to weld thin sheets of metal with this process. And. . Ans: One of the best electrodes to use for sheet metal is the 6013 rod. This is a fast-freeze rod that works well on thin gauge steel. The 6011 rods are also recommended for welding .

Sheet metal welding is a process that seems relatively simple at first glance – connecting several metal parts with the help of high temperatures and filler material. However, there is a lot more to it than just this explanation, which is why this article would try to explain basic welding methods and offer several tips for sheet metal welding.

If you are welding sheet metal, make sure the equipment you are using is designed for welding sheet metal. You should also make sure that the position you are welding from is clear of other metal parts. Summary of How To Weld Sheet Metal On A Car. Wet welding is the process of sticking metal components together with melted metal. How Do You Use a Stick Welder to Weld Thin Metal? The other name for the stick welding procedure is SMAW (Shielded Metal Arc Welding). This welding technique is older as compared to other types. However, it’s an easy procedure that guarantees you potent welds. Image Credit: vespaburoks, Pixabay. If you’re using stick welding, the anode gets . Gas welding is the simplest method of welding which puts some gases to melt the parts of sheet metal which in turn get fused when melted. Commonly it uses gases like oxyacetylene and oxygen. This method is highly .

How To Weld Aluminum With a Stick Welder. Stick welding aluminum follows most of the basic stick welding “rules.” But there are some points unique to stick welding aluminum, and they are worth reviewing. 1. . A spool gun is a great way to MIG weld aluminum without changing the MIG welding machine from steel. All you need to do is connect the spool gun to the proper locations on the machine, and you’re ready to weld .

Sheet Metal Welding. Laser Tube Cutting Services. CNC Machining. CNC Machining. CNC Milling. CNC Turning. Value-Added Solutions. Rapid Prototyping. Custom Assembly Services. . should be used for something other than cast aluminum. Stick welding or arc welding, is a process with a high heat input that can crack cast aluminum.

The thinnest metal that you can weld with a stick welder is 1/16 ″ (1.6mm). You can do thin metal welding of more than 1.6mm if you are experienced. In addition to the experience of doing thin metal welding, you must use good electrodes. What Power Supply Is Necessary For Thin Metal Stick Welding?MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. . You can also use an inverted-based power source for working on a thin aluminum. Aluminum alloys for sheet fabrication are 5052 or 3003 .

welding 24 gauge sheet metal

thin metal welding tricks that not all know. why didn't the welder tell this secretThis is a square tube welding technique, especially how to weld thin squar. Sheet metal welding is a crucial manufacturing process that helps join and assemble metal structures. . and considerable strength. Also, it’s compatible with different welding processes, including MIG, TIG, and stick welding. Aluminum’s lightweight and corrosion resistance makes it valuable for welding, especially in aerospace and . Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs . and considerable strength. Also, it’s compatible with different welding processes, including MIG, TIG, and stick welding. Aluminum’s lightweight and corrosion resistance makes it valuable for .

Overhead MIG Welding; Can You MIG Weld Aluminum Without Gas? Stick welders. Welding Rods Sizes; 7014 vs 7018 Welding Rods; 6011 vs 7018 Welding Rods; TIG welders. Mig vs Tig Welding; TIG Welders for Aluminum; Plasma Cutters. . Yes, you can stick weld sheet metal less than ⅛’’ thick, but you will need the right machine and a good set of .There is no hard and fast rule with the thickness under which you shouldn’t use stick welding.But there is a fair idea of what constitutes a thin metal and below which using stick welding might become difficult. A lot of people consider anything less than 3/16” to be thin so below this thickness stick welding can start creating problems or can become difficult to handle. ZOFORTY Welding Coupons - 12Pack 6061 T6 Aluminum Sheet Metal 2 x 4 x 1/8 Inch Aluminum Plate Weld Practice Kit for MIG TIG Stick MMA Arc Welding Practice Kit for Beginners dummy Luckyweld Welding Practice Kit, Mild Steel Welding Coupons 2×4 Inch 24 Pcs, Suitable for Novice MIG, TIG, Stick, Arc,MMA Welding Kit (Mild steel)Stick Welding Thin Metal. Stick welding is an industry's favorite welding method due to its low cost and high penetration and depositions. It allows you to complete the job quickly and cheaply, which is essential in large-scale applications, but the lack of heat control doesn't make it a favorable thin metal welding option.

iprimio cat litter box enclosure stainless steel litter box

In this article, we will explore effective techniques to prevent warping in thin metal during the welding process. Whether you are a novice welder or an experienced professional, these tips and tricks will surely help you achieve flawless welding results without any distortion.

stick welding aluminum sheet metal|welding 16 gauge sheet metal