how to seal electrical fixture boxes with quick flash If you’ve set out to start tightening your ceiling plane—typically the best place to start air sealing—you’re probably going to need to air seal at least a few electrical penetrations for light fixtures, pretty much right away. Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding.

0 · seal holes in electrical box

1 · how to air seal electrical box

2 · attic electrical box sealing

What Does a Sheet Metal Mechanic Do? A sheet metal mechanic works with various thin sheets of metal materials to fabricate, install, and repair products and parts made from sheets of metal. Their direct supervisor may be a sheet metal supervisor, shop manager, production manager, or general contractor depending on their place of employment.

seal holes in electrical box

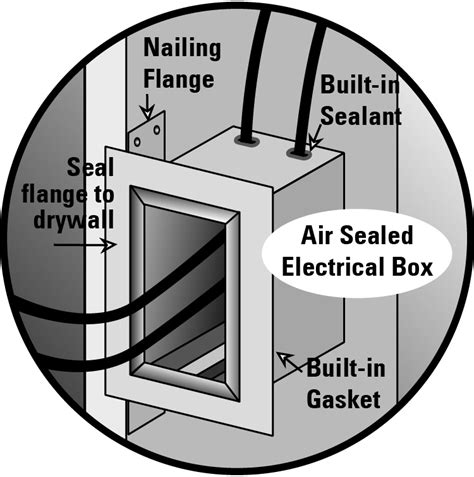

This blog provides guidance on the best practices for air-sealing electrical boxes, outlining key tips and recommending reliable products suited for the job. With the right materials and techniques, you can effectively air-seal electrical boxes and minimize air leakage.Even though light fixtures fasten tight to the ceiling, there’s enough of a gap to let air flow through the many holes in and around the electrical boxes they’re fastened to. In this video, Mike Guertin shows how to caulk these penetrations.

attaching ground wire to electrical box

QuickFlash is a weather proofing panel for sealing your electric protrusions. Quick, easy, no mess, no caulk. these panels will save you time and money. h. Any builder who has struggled to maintain a continuous interior air barrier or strived for a soundproof wall will tell you that the weak link is always . If you’ve set out to start tightening your ceiling plane—typically the best place to start air sealing—you’re probably going to need to air seal at least a few electrical penetrations for light fixtures, pretty much right away.

How to Air-Seal a Ceiling Electrical Box in an Attic. By MIKE GUERTIN | November 4, 2010. Thermal Bypass Checklist package (50+ details). Video Transcript: Here we have an . Seal Around Flush-Mounted Boxes, Behind Electrical Cover Plates. Another simple step for better outlet insulation is to apply foam or caulk into the gap around the flush-mounted box, behind electrical cover plates. .

From a code perspective, it is important to keep the volume of the box the same. While using electrical tape to seal the holes in an electrical box is likely better than nothing, I don't suspect it will survive the heat of a fire for .Hi there. My builder just finished insulating our attic with blown in insulation. Unfortunately I only realized after the fact that the electrical junction boxes were only spray foamed where the romex enters the box. They did not spray foam . One crucial element of this is properly sealing outdoor outlet boxes to protect them from the elements. Whether you are a seasoned DIY enthusiast or a homeowner looking to safeguard your outdoor electrical .

I came across some "old work" round boxes today that require a 3-1/2" hold saw, and look like they might seal well. I also came across "mud rings" for square and round electrical boxes that would get the required offset to cause the .These fittings connect liquid tight flexible conduit to fixtures, boxes, or enclosures where a 90-degree angle is needed. One side as a sleeve that pushes onto the conduit, forming a tight seal that stands up to wet and moist environments. The other side inserts into a fixture, electrical box, or enclosure and tightens down with an included . Note: This video only contains music, there are no captions.In this Vine-style video learn how to identify electrical boxes in your attic and seal leaks arou. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

OK, so we’re going to seal up all of the knockouts, and we’re going to seal the drywall to the rim of the electric box. And in this case, because this has the potential to get warm, and even hot, because of the electrical fixture below, I’m going to use some fire-blocking sealant. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . I watched a few do-it-yourself tutorial videos and in a couple of them they mentioned sealing the electrical boxes to the ceiling. . (116°C). Do not apply GREAT STUFF™ foam around heaters, high heat lamps or recessed lighting fixtures, radiators, furnaces or fireplaces where it could contact heat conducting surfaces. Do not use GREAT STUFF .Here we have an electric box in a ceiling for a light fixture below. All of the knockouts in the sides of the box have little gaps, as well as where the wire itself goes through. . Sealing a Ceiling Electrical Box; Sealing Wall Intersections; BONUS: Materials Overview; Sealing Ductwork; Sealing Soffits and Chases; Insulation Ventilation in .

Sealing the electrical JB to the sheathing/wrb and/or siding depends on the specific box and siding, your electrical sub should be able to advise you and select the proper box for the job. They do this routinely. I will not comment on your dual profession status, but . Another option is to install a PVC conduit through the wall and flash it with a QuickFlash flashing. Leave the conduit long so that the stucco applicator can install the stucco right around the conduit. Then trim the conduit back and install a surface mount fixture box, sealing the box to the surface of the stucco. One advantage I see with the Arlington flanged fixture panels is that it combines the flashing panel and electrical box into the same unit, whereas the Quickflash panels require purchasing specific compatible electrical boxes - and from looking at the list of compatible boxes, they are not always readily available.

With junction boxes, you can lay the insulation right over the boxes. No harm in that at all. One tip: caulk around the box where it meets the drywall and seal any holes in the junction boxes first. It will reduce air flow from the living area into the attic . The other half of it, and some would argue the most important half, is that you must air seal the walls/ceiling. Just about every penetration in your home is because of an electrical box, so it is crucial you air seal electrical .Another common cause of gaps is using the wrong size lightbox. If the lightbox is too small for the electrical box it’s mounted to, there will be gaps around the box’s perimeter. The other side of that coin is using a light box that’s too big for the . This gives you something to flash, and provides a flat surface to mount the fixture (which is especially helpful in cases like lap siding that would otherwise set the light at an angle). . come back and mount the light fixture to the box. If you ever want to change out the light fixture for something else, it's a quick and easy process that .

Once the electrical connections are secured, position the fixture back onto the mounting surface or junction box. Align it carefully, taking care not to disturb the freshly applied sealant. Use the appropriate screws or fasteners to secure the fixture in place, ensuring that it is stable and flush against the mounting surface. In my prior experience, the electrical box was always placed snugly next the fixture. How does one meet electrical code when there is a wooden spacer? The photo shows the Hardie board siding (yellow) with a 1.5-inch-thick wooden block (white) with a roughly 3.75-inch-diameter cylindrical hole. This video demonstrates how to flash a square or rectangular electrical box using Lightning Flash Corners and Fortiflash waterproof membranes by The Fortifib. Electrical - AC & DC - large gap between electrical box and outside fixture - just installed a small fixture outside and theres about a finger of space between the box and the fixture. it's installed per directions. i understand some silicone is appropriate but didnt think there should be such a large gap. Also, if

How do you mount a light fixture on an outdoor exposed 4'' round box ? The fixtures are usually just a little bit bigger diameter and so the gasket doesn't stay in place. His are 5 1/8 " lights. For 1 1/2' deep boxes, I usually layer two 3/4" composite trim blocks and cut out a 4" hole which hides the round box. This will seal it and keep water from leaking. Same thing with the electrical box. There would be a hole in the back and a wire going through that hole into the building. Water could seep between the electrical box and the mounting board into that hole. So again use caulk around the back of the electrical box before mounting.

Framing small boxes to prevent insulation from touching fixtures is a common solution to the non-contact rule. The boxes do not have to have lids since the code requires the tops of the enclosures protecting fixtures are open. Use one-inch thick boards to create barriers and attach the boards to the adjacent ceiling joists. - Flash Point: Over 550 °F (285 °C). - Other Properties: Non-conducting, non-deteriorating, non-toxic, non-corrosive, non-staining, non-curable; 99% solid, coil-based. . EPCO Duct Seal Compound is used to seal around junction boxes, flashings, service mast, and cable entries. . per the electrical inspector. Save Share Reply Quote Like .

Proper sealing prevents water from entering the electrical components, which could lead to short circuits, electrical shocks, or damage to the light fixture. The process typically involves using waterproof sealing components, such as conduit fittings, junction boxes, and sealants, to create a watertight barrier around the cable connections and .

how to air seal electrical box

attic electrical box sealing

atlantic electric cool box 24l 12v

Metallic fabrics are a surefire way to make a statement, whether in bold evening wear or as an accent in an everyday look. But how do you find the perfect metallic fabric, and what are the different types? Learn all this and more in our Zelouf guide to metallic fabric.

how to seal electrical fixture boxes with quick flash|attic electrical box sealing