how to increase part count in cnc machine The default setting (parameter 6700#0 = 0) of the machine increments the part count by 1 whenever M02, M30, or the M-code number specified in parameter 6710 (which . With over a dozen available processes, including CNC machining, 3D printing, sheet cutting, injection molding, Rapid manufacture is your one-stop shop for custom manufacturing. Get instant pricing, project lead times, and DFM feedback.eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software. We offer CNC Milling and .

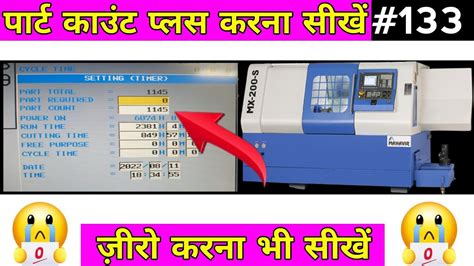

0 · how to increase part count in cnc machine

1 · how to increase and decrease parts count in cnc

2 · Using Macro Variables for Accurate Part Counting in CNC

3 · How to get Part Count with Fanuc

4 · How to Increase Part Count In CNC Machine

5 · Easy part counting using tool offset page.

6 · CNC Machining

7 · Basic Part Count Configuration

8 · 5 Things That Affect CNC Accuracy (& How to Fix Them)

Manufacturer of CNC Router Kits for hobbyists, woodworkers, and craft enthusiasts.

in this video i explained how to increase and decrease parts count in cnc machine in various methods The default setting (parameter 6700#0 = 0) of the machine increments the part count by 1 whenever M02, M30, or the M-code number specified in parameter 6710 (which .

How to Increase Part Count In CNC and Vmc Machine with Fanuc Control. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test. If anyone wants an easy to use and accurate part counter, try this line of code right above your M30. We use it a lot. G10 L10 G91 P30 R6; Did not see this suggestion here .Increment the part counter by M code or Macro. The standard part count M-codes works for nearly all machines/controls. If you have not added an M-code or Macro for incrementing part counts in your code, you must do so. how to increase part count in cnc machine | how to edit part count in cnc machine | fanuc part countfacebook Page = https://www.facebook.com/profile.php?id=1.

how to increase part count in cnc machine

One of the most effective ways to increase your part count is to optimize your tooling. Tool optimization means selecting the right tools for the job, ensuring that your tools .

wholesale cnc machine parts factory

Testing the count is really simple: Put the machine into MDI mode. Clear any existing MDI contents; Turn the feed and rapid overrides to zero; Enter the part count command from are count to use (M30 / M-CODE / .Learn how to use macro variables for part counting in CNC machining. Covers setting up counters in CNC programs and FactoryWiz configurations.

Here, we will discuss 5 of the most important faults that will jeopardize your CNC machine accuracy. We will also disclose how to check and improve them to get better . CNC machines have revolutionized the manufacturing industry by automating the process of cutting and shaping materials. However, the efficiency of a CNC machine is essential to ensure a profitable business. Calculating the efficiency of a CNC machine is not only about maximizing output but also minimizing waste and reducing downtime. Paragraph 2:how to increase part count in cnc machine - First of all, there are many types of machine tools, and there are differences in processing standards. Operators must have a certain professional level, such as having an operating license and understanding computer programming. Secondly, the maintenance personnel must have certain professional .

How to increase part count in fanuc control | Parts count edit in fanuc control #fanuc #cnc #vmcHello दोस्तों इस वीडियो में हमने पूरी .how to increase part count in cnc machine - China BoYang Hardware is a high-tech enterprise focusing on the design,R&D,manufacturing,sales and service of household hardware.The main products are: CNC machining parts,Stamping,Injection,die-casting,PRECISION CNC MACHINING PARTS, CNC ALUMINUM PARTS.Welcome to call or email to discuss business . For a lathe, you can use this version: G10 L10 P30 U.0001 You can also use M97 calls to increase the real parts counter: First, make sure setting 118 (M99 bumps M30 counter) is ON. The next step is to add a sub-routine like this example: M97 L5 P1000 (Loop 5 times) G105 (Barfeed) M99 (Repeat program and get 6th part count) M30 (End Program) N1000 (Beginning . The reason I say back on is that the "parts count total" is at 501, telling me that it was on at some point. I'm thinking that it was turned off so that the machine could not tattle tell on its previous operator. Correction from previous response This "new to me" machine does not activate a parts count even on a single run program (ending with .

Hi folks! After spending a career in front of Fanuc based machines, I am now tasked with learning the Mazak. I have a few questions and will break them up into separate entries here. First off, the machine is a VTC250D/50 and the controller is a Mazatrol Matrix Nexus 2. I attended Mazak’s. Let's learn about how to count parts on any CNC machine #cncprogrammingcourseshare with your friendsCNC course Playlist link.https://www.youtube.com/playlist.how would the machine know how many parts it's made? It seems to me from the document you linked, that you're thinking of using custom macro variables to do it? You'd just need to pull up that macro variable, and at the end of every part program you want to count, have some sort of line of code that would say +1 to the macro variable you're .

However, as beneficial as CNC machines are, they are still limited by their capacity to produce parts. In this article, we will explore some ways you can increase the part count in your CNC machine, so you can improve your overall productivity. 1. Optimize Tooling. One of the most effective ways to increase your part count is to optimize your .Hello friends, Welcome to our YouTube channel HPDC & CNC SOLUTIONAbout In this video how do we reset the parts counter and runtime of no fanuc.

Determining part counts for Fanuc machines Standard Machines (not looping the program) Fanuc machines will either part count on M30/M02 or a custom M code specified. To enable the machine to count on and M30/M02 parameter 6700#0(PCM) must be 0. If .Increasing machine shop profits requires a multi-faceted approach focused on reducing machining cycle times, minimizing downtime, optimizing processes, and ensuring on-time delivery of parts. By implementing these strategies, machine shops can enhance productivity, reduce costs, and improve customer satisfaction, ultimately leading to a more . However, as beneficial as CNC machines are, they are still limited by their capacity to produce parts. In this article, we will explore some ways you can increase the part count in your CNC machine, so you can improve your overall productivity. 1. Optimize Tooling. One of the most effective ways to increase your part count is to optimize your .About Press Copyright Contact us Creators Advertise Press Copyright Contact us Creators Advertise

Understanding Part Count. Part count is the number of parts that can be produced in a single run on the CNC machine. The number of parts you can produce depends on the size of your CNC machine, the complexity of the parts, and the production time. Setting the part count is critical because it determines the amount of raw material and the time . #3901 should be your part count value. test it by forcing a number in the counter on the control, then go to MDI and type #500=#3901 and see if you get that value in your #500 on the macro variable page. This may not show up right away, you might have to type it 2 or 3 times before it shows up. Also #3902 is the number of required parts value.

Rigidity isn't everything. There's also damping and ability to accelerate/decelerate. Also don't count out the importance of serviceability and ease of alignment/assembly. To increase rigidity, "boxing in" is the typical concept. Instead of a flat plate, build in vertical elements which will reinforce the plate.I'm designing a CNC machine in CAD which I intend to use for cutting out longboards from blanks, and since longboards can get fairly long it's not as easy to find suitable parts like it is for smaller format hobby machines. So I was wondering whether a CNC program such as Mach3 could be made to cut something out diagonally between opposite . © 2024 Google LLC You need to evaluate how you are using your machine envelope. And evaluate how much time it takes to setup the machine each time you machine a batch.

#haw to change the part Count on CNC machining#cnc machine part Count change kese kare#cnc machine part Count edit#part Count ziro#fanuc cnc machine part Cou. I never use the parts counter simply because if you scrap a part your counts off. use this #505=#505+1 M30 goto your macros and set 505 to 0 and count away. if you loos a part then just change it in the 505 column. also say you are running 5 parts at once you can put #505+5 and get good counts. dont use any [] brackets since this throughs an alarm.

Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series; Toolroom Mills; Compact Mills; Gantry Series; SR Sheet Routers; Extra-Large VMC; Double-Column Mills; Desktop Mill; Control Simulator; Mill Automatic Parts Loader; VMC/UMC Side-Loading Automatic . Standard Cycle - manually loaded part. In this case the machine should count on an M30 or M02. However, some machine tool builders (MTB) like to create their own M-Code to count with. Below you can find out if your machine counts on M30 / M02 or just the MTB's M-Code. Looping Cycle - robot loaded / pallet change machine / automation Hello Friends, CNC HUB INDIA Welcomes You. We are here to share our CNC, VMC, CAD and CAM knowledge with you in HINDI and English. Your feedback is valuable .

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

how to increase part count in cnc machine|Basic Part Count Configuration