beading operation in sheet metal Adding specific patterns of lines, known as beads, to sheet metal fabricators can help prevent it from bending or vibrating. This process enhances the durability of the metal and allows for creative customization for various .

Hi guys, i was wondering where do u put your soul points into? strength,crit chance , crit damage?

0 · types of sheet metal bending

1 · sheet metal bending standards

2 · sheet metal bending dies

3 · maximum thickness sheet metal bending

4 · bending tool for sheet metal

5 · bending sheet metal 90 degrees

6 · beading process in sheet metal

7 · beading machine for sheet metal

Shop Women's White House Black Market Silver Size M Tops at a discounted price at Poshmark. Description: An intricate, face-framing twist lends visual interest to this top in our striking metallic chrome.

types of sheet metal bending

Most sheet metal bending operations involve a punch die type setup, although not always. There are many different punch die geometries, setups and fixtures. Tooling can be specific to a bending process and a desired angle of bend.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be processed.

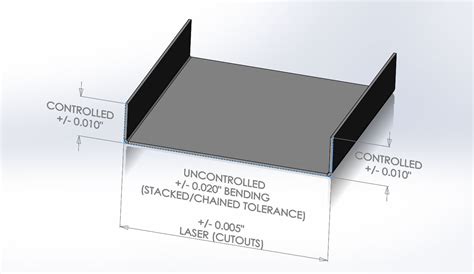

sheet metal bending standards

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies .

Beading is one of the common bending operations which are used to form beads at the end of the sheets. In beading, the periphery of the sheet metal is bent into the cavity of the die as shown .

Mark Simpson demonstrates how to use a bead roller to roll flanges and beads when fabricating sheet metals.

Adding specific patterns of lines, known as beads, to sheet metal fabricators can help prevent it from bending or vibrating. This process enhances the durability of the metal and allows for creative customization for various .

Drawbeads are used to control the flow of sheet metal into the die cavity during the drawing operation in order to produce an optimal stamped part with minimum material usage. Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead.

Outer sheet metal Draw-OP engineering relies on drawbeads to achieve stretch requirements for quality stamping. One way to describe the draw bead is to generate appropriate geometries in CAD, import them, mesh those .

sheet metal bending dies

Most sheet metal bending operations involve a punch die type setup, although not always. There are many different punch die geometries, setups and fixtures. Tooling can be specific to a bending process and a desired angle of bend. Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The restraining forces created by draw beads are the result of bending/unbending the sheet under some level of stretching coupled with friction.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be processed. Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process.

Beading is one of the common bending operations which are used to form beads at the end of the sheets. In beading, the periphery of the sheet metal is bent into the cavity of the die as shown in following figure.Mark Simpson demonstrates how to use a bead roller to roll flanges and beads when fabricating sheet metals. Adding specific patterns of lines, known as beads, to sheet metal fabricators can help prevent it from bending or vibrating. This process enhances the durability of the metal and allows for creative customization for various projects.

Drawbeads are used to control the flow of sheet metal into the die cavity during the drawing operation in order to produce an optimal stamped part with minimum material usage.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead.

Outer sheet metal Draw-OP engineering relies on drawbeads to achieve stretch requirements for quality stamping. One way to describe the draw bead is to generate appropriate geometries in CAD, import them, mesh those surfaces, and include them in the computation of the forming analysis.Most sheet metal bending operations involve a punch die type setup, although not always. There are many different punch die geometries, setups and fixtures. Tooling can be specific to a bending process and a desired angle of bend. Draw beads have become the most efficient method to provide restraining forces to draw complex-shape components from sheet material without wrinkles and splits. The restraining forces created by draw beads are the result of bending/unbending the sheet under some level of stretching coupled with friction.These types of beading machines and processes are especially used for cold forming sheet metal parts. In this case, the forming step comprises inserting the sheet metal part to be processed.

Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead geometry and binder forces, exploring how they impact the overall stamping process.Beading is one of the common bending operations which are used to form beads at the end of the sheets. In beading, the periphery of the sheet metal is bent into the cavity of the die as shown in following figure.

Mark Simpson demonstrates how to use a bead roller to roll flanges and beads when fabricating sheet metals. Adding specific patterns of lines, known as beads, to sheet metal fabricators can help prevent it from bending or vibrating. This process enhances the durability of the metal and allows for creative customization for various projects.Drawbeads are used to control the flow of sheet metal into the die cavity during the drawing operation in order to produce an optimal stamped part with minimum material usage. Sheet metal stamping is a crucial process in the manufacturing industry, enabling the creation of intricate and precise components. In this post, we will delve into the intricacies of bead.

code for fastening wire in junction box

maximum thickness sheet metal bending

bending tool for sheet metal

bending sheet metal 90 degrees

With great thanks to the Person family, Robbie Hare and the support of all of our friends and family, we are proud to announce the new ownership of White County Metal & Fabrication! (Formerly White.

beading operation in sheet metal|sheet metal bending standards