cnc machining applications Applications Engineer-CNC Machine Tools. Technical Career Services. Elk Grove Village, IL. Typically responds within 3 days. $90,000 - $110,000 a year. Full-time. Monday to Friday. Easily apply. We would also consider a Manufacturing Engineer, CNC programmer off the “shop floor”, or a fresh grad with CNC tools and CNC programming experience. Chairs like these make for a great option in any home looking for a touch of schoolhouse style: crafted from a powder-coated metal frame with a manufactured wood seat, it features an understated Windsor back silhouette and clean-lined design perfect for a modern farmhouse.

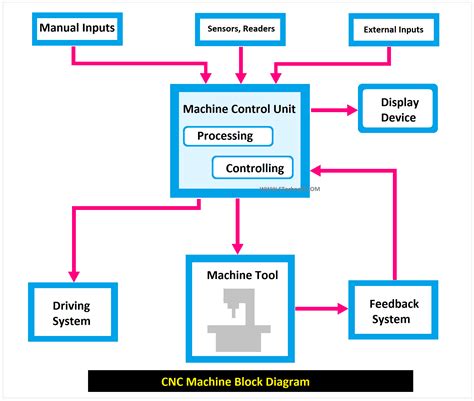

0 · schematic diagram of cnc machine

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

Another potential disadvantage of CNC machining is the limitation on part sizes. CNC machines have fixed dimensions, which can restrict the size of parts they can produce. Each CNC machine has a specific working envelope, determined by the size of its: l Bed l Spindle l Axes

From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. Let’s get straight to it! Industries That Use CNC Machining. CNC machining prototype productions .We have established a world leading position in front axle machining. Truck manufacturers and suppliers use our UNITWIN CNC machine to produce more than 2 million front axles every year.. For the complex rear axle machining we also have a dedicated solution: our UNIAXLE.With this new CNC machine you can machine cast iron as well as steel welded rear axles to the .CNC machining has applications in the automotive industry when manufacturing of high-performance custom parts is required. For example, the Dutch company PAL-V, designs Personal Air and Land Vehicles. These are essentially the .Applications Engineer-CNC Machine Tools. Technical Career Services. Elk Grove Village, IL. Typically responds within 3 days. ,000 - 0,000 a year. Full-time. Monday to Friday. Easily apply. We would also consider a Manufacturing Engineer, CNC programmer off the “shop floor”, or a fresh grad with CNC tools and CNC programming experience.

schematic diagram of cnc machine

products made by milling machine

CNC machining’s flexibility allows for the production of various part geometries according to the specific requirements of different industries and applications. Incorporating these techniques into the CNC machining process results in a diverse range of end products with precise dimensions and intricate details. By categorizing CNC machining applications based on their manufacturing possibilities and uses, you can understand how this technology is harnessed across different domains. Rapid Prototyping. CNC machines excel in rapid prototyping due to their high level of autonomy and efficiency. Once a digital design is finalized, machinists can swiftly . CNC Machining for Industries: 5 Applications for Military & Defense Though military requirements for equipment and supplies can vary, products manufactured for the defense industry must be able to operate effectively in the harshest environments.

Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) CNC milling machines are among the most versatile and widely used in the industry. They operate by rotating a cutting tool against a stationary workpiece, allowing for intricate shapes and designs to be crafted with high precision .

CNC machining has revolutionized the manufacturing industry, enabling the production of complex parts with unparalleled precision and speed. But what exactly is CNC machining, and how does it work?In this beginner’s guide, we’ll dive into the world of computer-controlled manufacturing and explore its applications, advantages, and future prospects. CNC Machining: Milling and Turning Definition and Significance of CNC Machining. CNC machining, short for Computer Numerical Control machining, is a manufacturing process that employs computerized controls to guide the movement of machine tools. This precise control enables the fabrication of complex parts with exceptional accuracy and .Known for high precision and speed, this machine serves well in various sectors such as aerospace, automotive, and electronics. It facilitates the production of components ranging from small intricate parts to larger assemblies. Its design emphasizes reliability and adaptability to different machining applications.

canopy junction box

industries that use cnc machines

cantex weatherproof electrical box 2-gang 2-inlet pvc model 5133392 pdf

A type of milling cutter, a cutting tool used in industrial milling applications. It is used in CNC machining to cut and shape the workpiece. Collet: A holding device—specifically, a subtype of chuck—that forms a collar around an object to be held and exerts a strong clamping force on the object when it is tightened.CNC machining has brought a new revolution in mold making process through its precision and meticulous techniques. CNC machining brings multiple processes by which you can create the finest quality molds for different applications. CNC Milling Machine. These machines are well known in CNC machining and are regularly used in mold-making operations. 3. CNC (Computer Numeric Control) Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone. In . CNC machining Haynes alloys has become increasingly popular due to their remarkable properties and widespread applications. This blog post delves into the unique aspects of Haynes alloys. The challenges encountered when CNC machining Haynes alloys and the various applications where they truly shine.

Applications of CNC Machining in Various Industries Aerospace Industry. CNC machining and the aerospace sector have a long history together. Metal aircraft parts are machined with the highest level of accuracy. For applications that .

In the vast realm of manufacturing and production, CNC machining applications are as diverse as they are integral. From small-scale industries to major multinational corporations, the range of CNC machine uses . CNC machining for automotive applications has been a driving force behind many manufacturing advancements. Metal Fabrication. CNC tools are used in the metal fabrication industry for various projects. Architecture CNC machining is also used to create art and decor. For instance, the intricate stonework in kitchens is made using CNC-controlled . CNC machining has wide applications in industrial part manufacturing due to several advantages. Below are a few benefits of the process over other manufacturing operations. Accuracy and Precision. CNC machining is accurate, allowing product manufacturers to make parts according to the intended design. Aside from that, it has high precision and .

They are applicable in aerospace parts, sports equipment, and high-performance applications. Applications of CNC Machining. Industry Examples. What are CNC machines used for? CNC machining is crucial to manufacturing agriculture, medical, and consumer goods parts. In the oil & gas industry, it accurately produces valve, drilling, and pump .Applications of CNC Machining. CNC machining plays a pivotal role across a wide spectrum of industries, thanks to its ability to deliver precision and efficiency. Understanding how it is implemented can provide insight into its vital functionalities. These applications encompass diverse fields from automotive to medical sectors. CNC machining is one of the most common manufacturing techniques in various industries, as it can create simple to complex structures with high speed and accuracy. However, the technology is diverse, each suiting different applications. CNC turning is a typical standard in CNC machining. It is the go-to machining process for machining rounded objects.

different type of cnc machines

But, 5-axis CNC machining is tagged as expensive and not easy to access, it that true? Here is a quick guide to 5-axis CNC machining, you will discover how 5-axis CNC machining works, applications, cost, advantages, and comparison amongst 3-axis, 4-axis, and 5-axis CNC machining in the following paragraphs. Part 1. What is 5-axis CNC machining?

CNC Precision Machining Applications. CNC Machining Motorcycle Parts. CNC Precision machining is gaining popularity in the manufacturing industry because of its numerous applications, low cost, and quick turnaround times. The method is frequently utilized in a variety of industries, including:

These are some common applications of CNC machining: Aerospace . CNC machining emerges as an invaluable tool in an industry where absolute precision is absolutely non-negotiable. From intricately designed engine parts to robust airframe structures, CNC machines play a pivotal role in manufacturing by producing components that meet and exceed .

This section explores the most commonly used materials in medical CNC machining and their applications. Metals. Metals are widely used in medical CNC machining for their strength, durability, and biocompatibility. Key metals include: Stainless Steel (e.g., 316L, 304) Acrylic CNC machining finds applications in many various industries. Signage and Display. Acrylic’s transparency and ease of machining make it an ideal choice for signage and display applications. CNC machining allows for the creation of intricate logos, lettering, and images with crisp edges and a polished finish. Located just outside San Diego in Poway, CA, Darmark Corporation is a precision CNC machine shop specializing in prototype and production applications. They have gained a reputation as a premier manufacturer in Southern California for their expertise in the cnc machining of high-temp alloys, as well as their skill in completing turn-key assemblies.

cape cod style metal gargage house

Shopping carts are primarily made of durable metals like carbon steel or stainless steel. These materials are chosen for their ability to resist corrosion and their ease of maintenance, ensuring that they last in a retail environment.

cnc machining applications|schematic diagram of cnc machine