sheet metal printing process Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: . $59.95

0 · printing on stainless steel sheet

1 · printing an image onto metal

2 · printer that prints on metal

3 · printable metal sheets

4 · photo printing on stainless steel

5 · inkjet transfers printing on metal

6 · ink lettering transfer onto metal

7 · digital photo printing on metal

The Eclipse 5/8" Diameter Room Darkening Rod features a unique bracket design allowing the curtain to wrap around the side of rod to block window sidelight. The wrap around feature also enhances privacy and reduces outside noise and drafts.

Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient operations. This comprehensive guide serves as your roadmap to navigating and leveraging .Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The .Table of Contents. 9 Steps in Sheet Metal Fabrication Process. Step #1: The Design Phase. Step #2: Material Selection. Step #3: Cutting the Metal. Step #4: Forming and Shaping. Step #5: . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

printing on stainless steel sheet

printing an image onto metal

Explore our in-depth guide on metal stamping, covering key processes, materials, precision techniques, and comparisons with CNC machining. Learn about surface finishes, die types, and how to select the best supplier for custom metal .The stamping process in sheet metal involves several key steps to transform flat sheets into shaped components. It begins with designing the part and creating custom tooling, including . What Is Sheet Metal Forming? Sheet metal forming entails taking thin, flat sheets of metal and manipulating them into fully formed 3D structures. The process transforms a basic raw material into complex finished products .

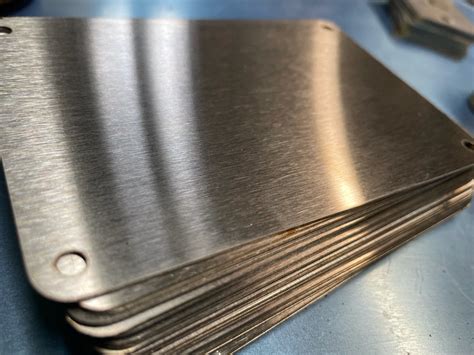

Sheet MetalPrinting Parts. How to Choose a Suitable Ink for Metal Silk Screen Printing. . Metal Silk Screen Printing Process. Below are the different processes when working with silk screen printing on metal. Making of artworks and .

Sheet metal blanking is a detailed process requiring accurate preparation, tooling setup, and quality control at each stage. Beska’s expertise guarantees that each blank undergoes thorough inspection and post-processing, providing your . The process, known as sheet metal laser cutting, can develop complex geometries rapidly and accurately in metals like steel, aluminum, . Read on to learn more about how integrating 3D printing with sheet metal . In the simplest terms, silk-screen in a metal finishing process that involves applying paint and elements of design to a piece of metal. More specifically, silk-screening (also known as serigraphy) employs the use of fine polyester mesh and a squeegee or blade to apply paint to a specifically designed section of metal.

metal detecting shadow box

printer that prints on metal

metal deck support bracket

How 3D Printing Can be Used in Sheet Metal Forming. Integrating 3D printing with sheet metal forming opens many doors for your product development, by paving the way for greater precision and creativity. Let’s explore how this integration transforms the process:The silk screen process on metal is a dynamic and adaptable method. This technology ensures precision and longevity with a wide range of industry applications. Automotive Excellence – Silk printing is resilient in ensuring that prints withstand the rigors of the road. This process produces sharp details that are both aesthetic and durable. It is a type of metal 3D printing process that works by fusing metal powder into a solid part. The process starts by spreading a layer of metal powder on a build platform and then melting it with a high-powered laser. . Sheet Lamination is a metal 3D printing technology process that works by layering sheets of metal to form the final product . Process development for 3D printing of new metal alloys can be time-consuming and variability in the printing outcome makes it even more challenging. Here, authors demonstrate an in-situ method .

What Do You Need to Print on Metal? 6. Step-by-Step Process of Printing on Metal (with Pictures) Step 1. Print Out the photo Step 2. Peel off the plastic from the metal Step 3. Place the panel onto the photo Step 4. Attach the print to the metal Step 5. Place the print and metal sheet in the heat press Step 6. Remove the print and metal sheet .

Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-s.Unlock the secrets of silk screen printing on metal! Dive deep into techniques, tools, and tips for flawless designs and long-lasting prints. . 8 Printing Process. 9 Curing Ink on Metal. . Do you need a reliable sheet metal parts manufacturer? Shengen is the place to go. We specialize in sheet metal laser cutting, bending, surface finish . Fig. 2 Radial riveting equipment and riveting process. Process selection and precautions of riveting (1) The size of the riveting bottom hole should be designed in strict accordance with the manuals of general or special equipment, standard parts, and should comprehensively consider the material, thickness, model, and strength requirements of the .

An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. The time spent by the engineer/operator during the full process cycle is documented and compared to the time it would take to make the corresponding tool by conventional metal machining. Usually, metal UV printing process is a simple process that involves the following steps; Step 1: Get all Tools and Accessories Ready for the Printing Process. . Screen Printed Sheet Metal. Screen printing uses less ink compared to UV printing. This therefore means it is more affordable.This unexposed metal is then etched away using an acid solution. The light-hardened parts of the surface remain raised above the etched-away space, resulting in the finished printing plate. The metal sheet is then mounted on a wooden block to make the printing process easier.

printable metal sheets

LOM is a type of sheet lamination process that can be used to create metallic 3D objects. Note that sheet manufacturing otherwise uses plastics or paper. . The Cons of 3D Metal Printing. 3D printing is not possible with all .

3D printing, otherwise known as additive manufacturing, has become a cornerstone manufacturing process for industries worldwide that use it to create plastic and metal parts with geometries that are impossible to achieve through .

Sheet-Fed Screen Printing . Sheet-fed screen printing is usually preferred for low- to medium-volume technical printing projects. The sheet-fed printing process requires an operator to load individual sheets into a press and then remove them after each pass, increasing overall job time. This combined with its size and run rate limitations .

UV Printing Process. This section will walk you through the process of printing UV on metal. It is a technique which combines creativity and precision. We will also discuss the tips and tricks for preparing metal surfaces for the best print quality. How to UV Print on Metal. It is essential to pay attention to every detail when UV printing metal.Metal’s natural oxide layer can sometimes be used to enhance the appearance of digital printing on metal sheet. Copper: Not as popular as the other metals listed. Copper can be UV-printed for specific niche applications. . While the initial curing happens almost during the printing process. The UV printing products may undergo more curing .The sheet metal bending process is very important for making strong and useful metal parts. At Beska, each step, from picking the right material to the final check, is done carefully to ensure great results. . Sheet Metal Materials; 3D Printing Materials; General Materials; Case Studies; Videos; Blog Menu Toggle. Industry Guides and Overviews .

Sheet Metal Prototyping using 3D Printing. Including metals in 3D printing marks a significant leap forward for prototyping. . Can CAD software help with the Sheet Metal Design Process? The CAD software provides powerful tools to design, modify, and analyze sheet metal designs. This software allows designers to visualize and validate designs .Formative manufacturing • Die casting: Die casting is a process in which molten metal is fed into a mold cavity under high pressure. Mold is made from hardened steel and contains the shape of the part to be molded. . 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional .

3D printing with metal is probably one of the most impressive process technologies currently available and offers companies many opportunities across all industries. At the same time, however, the process is very complex and requires a high level of expertise, particularly in the professional printing sector.

metal deck planter brackets

Sheet metal fabrication is a vital process that transforms raw metal into functional parts, ensuring accuracy and quality in every step. . Sheet Metal Materials; 3D Printing Materials; General Materials; Case Studies; Videos; Blog Menu Toggle. . The process is also well-suited for parts that need to withstand mechanical stress, as the material’s structural integrity is maintained throughout the machining process. Metal 3D Printing vs. CNC Machining: Dimensional Accuracy Metal 3D Printing: Metal 3D printing can achieve good dimensional accuracy, suitable for a variety of applications .

Extensive library of metal materials for machining, sheet metal fabrication, and 3D printing. Elastomers. Flexible materials for injection molding and 3D printing. Colors. . The rapid heating and cooling of the metal material during the DMLS process results in a buildup of internal stresses. While every build undergoes a stress relief .

Distributor of electrical power distribution enclosures. Various types include active wall mount, Ethernet, in-ceiling, raised floor, wireless access point, seismic and server enclosures. Various models offered. Vendor managed inventory (VMI) programs and stock items available. Meets AS9100 Rev C standards. Kanban and JIT delivery. More +

sheet metal printing process|printer that prints on metal