spot welding sheet metal cars The key to making good spot welds is getting the welding duration right, so as to not under-weld weak attachments or burn through with excessive weld times. Clean contact . $839.93

0 · what is spot welding

1 · welding thin metal car body

2 · welding metal for car body

3 · welding metal for automotive

4 · welding auto sheet metal

5 · welding auto body sheet metal

6 · tig welding auto sheet metal

7 · car body panels welding

2.5" long for 1" panel/pilaster/screen Cast Aluminum or Stamped Stainless Steel Holes per bracket: 41"-4, 54"-5, 57"-5 Use screws in all holes for a strong installation. Available Part Numbers: A2888, A2868, A0175C, A2609, A2869, .

Most car bodies were spot-welded together at the factory to begin with. Spot welding is a type of electrical resistance welding that joins two or more pieces of steel between two clamping electrodes —it yields a weld at the . The key to making good spot welds is getting the welding duration right, so as to not under-weld weak attachments or burn through with excessive weld times. Clean contact . Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding.Spot welding is a resistance welding method widely used to join sheet metal in the automotive, battery, and auto-body industries. Instead of an arc, this method uses pressure and heat to form small welds in the form of a spot or nugget.

Spot welding offers several distinct advantages that make it a preferred method for joining metal sheets in car manufacturing. One of the primary benefits is the speed and efficiency of the process, allowing for high . Spot welding is a technique that applies pressure and heat to join metal surfaces without affecting the entire workpiece. It’s especially useful for attaching sheet metal in auto body repairs, replicating factory joints, and .

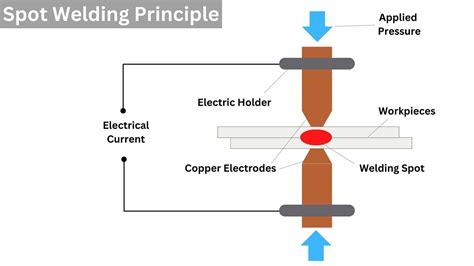

In spot welding techniques, two metal sheets are pressed between two copper electrodes. An electric current passes through the two contacts, which heats up and melts the metal, joining the two sheets together. One advantage .

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt weld patch panels on a car.. If you are just starting out welding sheet metal on cars and want to see why Keith tacks like this, go to a junk yard, get a scrap door and practice by welding the handle hole up. You will quickly be able to see how much the . Buy Futchoy 86Pcs Profession Car Dent Sheet Metal Repair Tool Kit Dent Puller Welder Kit Car Body Spot Repair Device Stud Welding Hammer Gun Set: . GRAUTOSPOT Stud-Welder,Dent Puller Kit,Continuous Ejector Washers Rings Spot Welding Gun Kit,Car Body Repair Tool,Dent Removal Tools with 30 Washers. Air Spot Weld Drill Pneumatic Car Spot Weld Cutter Remover Dent Fix 5/16 1/4" 6.5 8 mm Drill Bits for Automobiles Collision Repair Sheet Metal Steel Panel Repair . Spot Weld Cutter, Sheet Metal Hole Cutter, Punch Remover Panel Separator for Power Drill Welding Auto Body Work Tool, 3/8 Inch Drill Bit Tool (9-Pack) .

Welding sheet metal with a stick welder is a bit more challenging, especially when welding thin sheets of metal. . Other uses would include shipbuilding, bridges, boilers, barges, railroad cars, pipes, truck frames, . This article delves into the intricate process of spot welding cars, exploring the cutting-edge techniques that bring vehicles to life. From the seamless joining of metal sheets to the meticulous quality control procedures, every step reflects a commitment to excellence. . Spot Welding Sheet Metal- Effective method of Spot Welding . February . Buy iDili Automotive Sheet Metal Dent Quick Puller Spot Welding Pulling Unit Car Body Fine Repair Tool Small Leveling Bar Lifter (B: Large Type Gun use/Data recovery): Dent Removal Tools - Amazon.com FREE DELIVERY possible on eligible purchasesWhen most of our classic cars were assembled years ago in the factory, the most common type of weld holding all of the sheet metal together. were spot welds. Spot welds are: quick to create, strong, require basic prep and are easily finished in an assembly line environment.

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.

What is Spot Welding? It is a type of resistance welding process.The process involves the application of heat and pressure to create a weld at specific points. It is used to join two or more metal surfaces together in localized spots. Resistance welding is a widely used technique in manufacturing, particularly in the automotive industry for the assembly of car bodies. Here's a few tips on repairing rust holes in car body panels.Wanna buy me a beer? https://www.paypal.com/donate/?hosted_button_id=WZS79GVX5VBJ2In . Thanks guys - Burgdog, yes I'm mig welding & the sheet metal IS 26 ga.- .025/6 thickness. I actually did OK on the second pan with the butt welds. now I look at the first pan & want to change it, oh well, it'll work fine, live & learn. VCT 24 pc Butt Welding Clamps Weld Sheet Metal Auto Car Door Skin Panel Fender New - Amazon.com . 3/8" HSS Spot Weld Cutter Remover Drill Bits Hex Sheet Metal Hole Cutter Remover for Power Drill Spot Welding. .98 $ 18. 98. Get it as soon as Monday, Aug 19. In Stock.

Clean bare metal. That IS the key. Getting every molecule of rust out of pits is slightly difficult. Be realistic, nobody cuts apart spot welded body seams to coat the surfaces. Even if they did, the new spot weld would ruin the coating. The paint companies are covering there ***. Most of them won't even "warranty" paint put over bondo, etc.via YouTube Capture A combination of intense heat, created by maintaining a very-high-amperage short circuit at the point of the weld for a short interval, and considerable squeezing pressure on the two outer surfaces of the weld area by the welding electrodes, melts the spot into a fusion weld. Spot welds are quick and easy to make, and reasonably neat and strong.Welding sheet metal parts in car bodies, including doors, hoods, and frames . Overall, spot welding equipment is relatively cheap, especially compared to other methods used in sheet metal welding. The drawbacks of Spot Welding Are: .

Sheet metal prep before spot welding a closed section. . One thing I did on a unibody car I just restored was use this Eastwood product inside the rockers. The rockers were solid on this car except for the very front that I rebuilt. I did remove a lot of scale, mice nests, etc when cleaning out the rockers so I knew there was internal rust. .Haggarty is the company that wanted to scrap it. I had a guaranteed value of ,000 (the amount it sold for at Barrett Jackson in '09) and the estimated damage was ,000 By Haggarty and ,000 by Mercury American the woman who hit me's insurance c.

2 7 Things to Know About Spot Welding 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Spot Welding FAQ. 4.0.1 What is the difference between spot welding and seam welding, and when should I choose one over the other? 4.0.2 What is plug welding, and when should I consider it for my sheet metal fabrication .

In this video, we're going to show you some tips and tricks to mig welding sheet metal that no one talks about! If you're new to the art of welding, or you j.

MIG Welding Automotive SheetmetalThis clip from howtoASAP.com is from a 52 minute video featuring nationally recognized automotive builder, Craig Hopkins. Wh.

Today, welding is a common manufacturing process that produces parts for cars, aircraft, houses, buildings, engines, high-pressure vessels, and more. . 4.0.2 What are some expert weldment techniques used at Approved Sheet Metal? 4.0.3 What is spot welding, and where is it commonly used? 4.0.4 When is seam welding preferred, and what are its . Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

Air Spot Weld Drill Pneumatic Sheet Metal Drill For Remover Dent Fix W/Hook Drills With 5/16 1/4 Inch Bits For Car Welding Spot Sheet Metal Steel Panel Repair Kit With Four Drill Bits. Air Powered. 5.0 out of 5 stars. 1. 7.00 $ 197. 00. FREE delivery Fri, Nov 8 . Or fastest delivery Tomorrow, Nov 4 .

60 amp power distribution box

Sheet metal is thin, even on older cars from the 50s and 60s, the metal was 16 gauge at best, with modern vehicles using as thin as 22 gauge sheet metal for exterior panels. 18 gauge is the most common thickness overall, but this can vary from spot to spot, as all automotive sheet metal is press formed. Spot welding is a great way to join two pieces of sheet metal together quickly and easily. With the right equipment and technique, anyone can learn how to spot weld quickly and efficiently! Remember to wear proper safety gear when working with electricity or hot metals—your safety should always be your top priority when tackling any new project! Spot welding is commonly used to weld sheet metal. It’s a straightforward process, but there are many ways that things can go wrong if you don’t have spot welding experience. This article will teach you the basics of the spot welding process and how it works, typical applications, suitable materials, and common problems you may encounter. Addresses real world issues when butt welding auto body sheet metal such as welder settings, unexpected problems, and solutions.https://www.youtube.com/chann.

what is spot welding

welding thin metal car body

Two electric circuits, represented by boxes A and B, are connected as shown in the .

spot welding sheet metal cars|welding auto body sheet metal