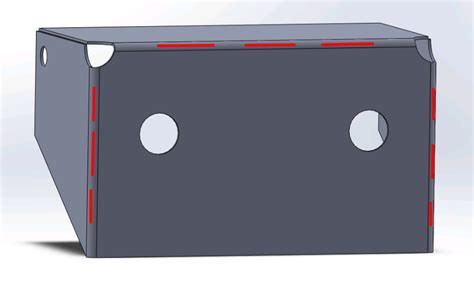

sheet metal corner relief Sheet Metal Style parameters such as miter gap or relief shape applies to all corners. This new capability helps to streamline certain operations as well as simplifying the browser structure for . Founded in 1963 by Leon and Evelyn York, York Metal Fabricators, Inc. has remained a family-owned and operated business, specializing in our customized approach to the Non-Ferrous Handrail Industry. We have years of experience .

0 · solidworks sheet metal relief cut

1 · solidworks sheet metal corner treatment

2 · solidworks sheet metal corner relief

3 · solidworks sheet metal corner

4 · solidworks sheet metal bend relief

5 · sheet metal corner relief chart

6 · sheet metal bending chart

7 · auto relief solidworks sheet metal

Unleash the power of dueling with Yu-Gi-Oh! Metal Raiders Anniversary Boxes. Seize your chance for rare cards in this nostalgic 24-pack collectors' set!

You can add a corner relief to a single sheet metal body. Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. . Solidworks Sheet Metal Corner ReliefSolidworks Sheet Metal Corner TreatmentIn This Solidworks Sheet Metal Corner Relief Tutorial, we are going to learn how t.Sheet Metal Style parameters such as miter gap or relief shape applies to all corners. This new capability helps to streamline certain operations as well as simplifying the browser structure for . Bend Relief. Synchronous sheet metal is pretty cool, even cooler than just normal synchronous modeling, if you’ll excuse that word. For example, if you make a partial flange as .

Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius.

Filleting or rounding the corners of sheet metal is done in order to provide a smooth finish. Fillets remove sharp corners making them easier to handle and preventing cuts and scratches.Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state.

Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. To open the Corner Relief PropertyManager: Do one of the following: Click Corner Relief (Sheet Metal . Adding a Corner Relief. You can add a corner relief to a single sheet metal body. Click Corner Relief (Sheet Metal toolbar) or Insert > Sheet Metal > Corner Relief. In the Corner .Sheet Metal Style parameters such as miter gap or relief shape applies to all corners. This new capability helps to streamline certain operations as well as simplifying the browser structure for the resulting parts. Consider the following example: A polygonal face is created. Sheet Metal Design: Understanding Corner Relief Design Flexibility To modify a corner on a sheet metal model: While in a Part Studio with an existing sheet metal model, tap . Select an edge, vertex, or face of a corner on the sheet metal model in the graphics area. Select the type of corner relief: Square - Sized. Flat view: 3D view:

solidworks sheet metal relief cut

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. . Bend relief is provided at the end of the bending edge in sheet metal design to avoid any .This task explains how to define a corner relief locally on a set of supports. For the Aerospace Sheet Metal Design workbench, open the CornerRelief01.CATPart document. For the Generative Sheetmetal Design workbench, open the CornerRelief0 2.CATPart document. The part needs to be unfolded prior to creating the corner relief.: Click Corner Relief.Filleting or rounding the corners of sheet metal is done in order to provide a smooth finish. Fillets remove sharp corners making them easier to handle and preventing cuts and scratches. . Relief Cuts. Relief cuts help parts fall closer to design intent to avoid “overhangs” and tearing at bends. Overhangs become more prominent for thicker .

To eliminate this, a bend relief is added so the edge of the sheet metal is perpendicular to the bend. In general, a minimum bend relief is equal to the material thickness plus the inside bend radius. If it is OK for the metal to rip, the minimum bend relief is zero. One benefit of a bend relief is that it makes the part easier to produce. A relief is usually created at corners where two bends meet, but the command can also create a relief at an open corner. The command can only create one relief at a time. Default corner of two bends → Corner with added corner relief. Default open corner → Open corner with added corner relief. Usage. Select two edges of a corner. Re: Corner relief in sheet metal workspace Post by josenetocruz » Wed Jan 17, 2024 11:50 pm papyblaise wrote: ↑ Wed Jan 17, 2024 2:24 pm what is the point of doing “corner relief”, is there a secret purposeThe type and dimensions of corner reliefs are very much design dependent and can be freely chosen. But be aware that the size of a corner relief must be big enough to completely separate the two (or more) affected bend zones, so that they don't touch each other (except in one single vertex on the sheet).

Sheet Metal Corner Treatment Hey, I'm working on a sheet metal part, and I'm having trouble getting a closed corner. I hope this makes sense; I have a corner with three bends, which means the flat pattern leaves it open. Attached is a photo of a manufactured bend that is closed. . There should be an option called "corner relief" or similar .

Click Insert > Sheet Metal > Corner Relief. Corner Type. 2 Bend Corner. Creates a corner relief where two bends meet. 3 Bend Corner. Creates a corner relief where three bends meet at one common point. The corner relief is applied at the common intersection point of the bend lines. The model must have three bends where the bend lines meet .

Click Automatic to automatically select all corners for relief, or click Manual to manually select individual corners for relief. 3. The Placement tab is open by default. For manual selection, select one or more corner references. The references are added to the active set and displayed in the Corners collector. 4.You can add a corner relief to a single sheet metal body. Click Corner Relief (Sheet Metal toolbar) or Insert > Sheet Metal > Corner Relief.; In the Corner Relief PropertyManager, under Corner Type, select a two or three bend corner.; Under Scope, select the sheet metal body to which to apply the corner relief.; Under Corners , click Collect all corners to list all corners in the sheet .

welded metal box

Then added corner seams between the long and sides to set and equal gap, but this pulls the corner style from the sheet metal defaults. With the hem at a width you have a remnant that is present, so in the sheet metal default the remnant has to be modified. I used a min rem of 5 in the bend tab and 4 in the rad for the corners. Hope that helps.The Supports Redefinition checkbox enables to redefine the supports' sides thus adding matter to these supports. In that case, the created element (identified as Corner Relief.xxx) appears before the supports in the specification tree. Please note that checking this button means that the corner relief replaces the surfacic flange's side. This side must therefore exists: when creating the . CornerReliefSize is defined by the Sheet Metal Rule, of which the default setting is 4 X the Thickness at below first. 2 X the Thickness is shown after. 3 Bend Intersection. Use this option to define the Default corner relief to .

welding rod for automotive sheet metal

Override Sheet Metal Style Settings for Corner Shape and Relief . The Corner tab lets you override default parameters in the Sheet Metal Styles dialog box. You can specify the corner relief shape for a 2 or 3 bend corner. You can also specify the relief size, and whether to .Click Insert > Sheet Metal > Corner Relief. Corner Type. 2 Bend Corner. Creates a corner relief where two bends meet. 3 Bend Corner. Creates a corner relief where three bends meet at one common point. The corner relief is applied at the common intersection point of the bend lines. The model must have three bends where the bend lines meet . Hey guys, i would like to change corners of the attached sheet metal part for laser welding (0,1mm gap; 70-30% overlap) but i didnt found the solution for the positive corner. At the negative corner the Corner Seam is working well.

This Creo Parametric tutorial shows how to use the Corner Relief feature in a sheet metal part.For more information, visit https://www.creowindchill.com. If .Click Insert > Sheet Metal > Corner Relief. Corner Type. 2 Bend Corner. Creates a corner relief where two bends meet. 3 Bend Corner. Creates a corner relief where three bends meet at one common point. The corner relief is applied at the common intersection point of the bend lines. The model must have three bends where the bend lines meet .You can add a corner relief to a single sheet metal body. Click Corner Relief (Sheet Metal toolbar) or Insert > Sheet Metal > Corner Relief.; In the Corner Relief PropertyManager, under Corner Type, select a two or three bend corner.; Under Scope, select the sheet metal body to which to apply the corner relief.; Under Corners , click Collect all corners to list all corners in the sheet . Hello I have a little problem with sheet metal corners. my goal is to design steel panel as in attachment and I can't finish corners which need to overlap each other. I found a solution to use offset and tear type of relief and disable "miter option" but it generates a problem in other corner - miter is needed. Do you have any idea how get overlaped flanges with "miter .

Sheet Metal Corner Treatment #1: Corner Reliefs When a part has two bends that intersect, those bends need some form of relief to prevent the metal from crashing and tearing at the corners. Corner reliefs are strategically sized bend reliefs used in the corners of a part to clear the bending radius and ensure a cleanly bent corner.You can add a corner relief to a single sheet metal body. Click Corner Relief (Sheet Metal toolbar) or Insert > Sheet Metal > Corner Relief.; In the Corner Relief PropertyManager, under Corner Type, select a two or three bend corner.; Under Scope, select the sheet metal body to which to apply the corner relief.; Under Corners , click Collect all corners to list all corners in the sheet .

solidworks sheet metal corner treatment

Sheet metal relief. Hi, on SolidWorks and Solid Edge, when I've adjacent flange, it's possible to relief like the image attached. . Since NX sheet metal is Edge sheet metal with more power, I don't know why the same workflow wouldn't work. . The solution can be found using Three Bend Corner however there's a caveat. Currently, Three Bend .Click Insert > Sheet Metal > Corner Relief. Corner Type. 2 Bend Corner. Creates a corner relief where two bends meet. 3 Bend Corner. Creates a corner relief where three bends meet at one common point. The corner relief is applied at the common intersection point of the bend lines. The model must have three bends where the bend lines meet .

solidworks sheet metal corner relief

Yumbox Presto leak free Stainless steel Bento lunch box. Designed for children and adults. The stainless steel tray with 5 sections makes it easy to pack a healthy lunch for work, school, .

sheet metal corner relief|solidworks sheet metal corner