sheet metal pattern development pdf When wanting to build a project, we need to first imagine it. The process of pattern development gives us the ability to take that visual . See more One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing .

0 · sheet metal pattern layout methods

1 · sheet metal layout software free

2 · sheet metal layout patterns pdf

3 · sheet metal fittings layout drawing

4 · sheet metal development drawing pdf

5 · pattern development in technical drawing

6 · free sheet metal layout patterns

7 · free sheet metal layout books

The three plus signs on both sides mean they are “looking for partners as a pair” while the minus signs mean they would also join without their partner. Garden gnomes are another sign.

sheet metal pattern layout methods

BCcampus Open Education believes that education must be available to everyone. This means supporting the creation of free, open, and accessible educational resources. We are actively committed to increasing the accessibility and usability of the textbooks we produce. ix See more◦ If using the online webbook, you can use the search bar in the top right corner to search the entire book for a key word or phrase. To search a specific chapter, open that chapter and use your browser’s search feature by hitting [Cntr] + [f] on your keyboard if using a . See moreWhen wanting to build a project, we need to first imagine it. The process of pattern development gives us the ability to take that visual . See moreThe webbook includes animations (GIFs) and videos. If you find the animations distracting, you can use the PDF or eBook version of the book instead, which uses images instead of animations. In the PDF, eBook (EPUB), and printed versions, the animations and . See more

In geometry we deal with many different shapes. All shapes are made up of various points, lines and angles. See moreSection 14.2. Drawing Pattern. Developments. Chapter Objectives. Explain how pattern development is used in the packaging industry. Identify the methods for processing sheet .From creating 2D patterns of 3D objects, to making sure roof panels are installed square, to locating duct runs and penetrations, geometry is used everyday by a sheet metal worker. This .

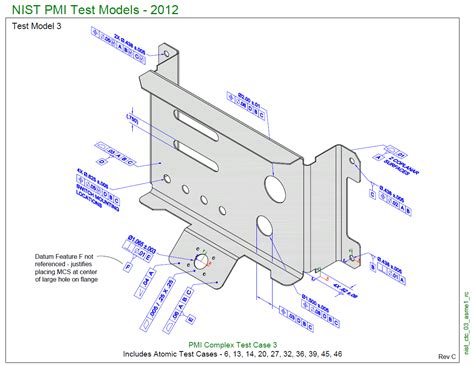

Pattern Development: Sheet Metal Level 1. Line E. Brian Coey. Download this book. This book covers all three forms of layout as well as geometric construction. It introduces the learner to the techniques used in .Practical sheet metal work and demonstrated patterns. Created Date. 12/13/2012 3:35:07 PM.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . Sheet metal drawing and pattern development : Dickason, A. (Alfred) : Free Download, Borrow, and Streaming : Internet Archive. by. Dickason, A. (Alfred) Publication .

The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles under-lying practically every problem that is . With videos and animations, the learner has an opportunity to play, pause, and rewind as they practice these techniques. This book covers material required for a level 1 sheet metal apprentice (Line E).The document discusses different methods for developing sheet metal patterns from objects, including parallel line development, radial line development, and triangular development. It .

Sheet Metal Pattern Development - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document discusses different methods for developing sheet metal patterns from objects, including parallel line development, radial line development, and triangular development. It also covers fabricating edges, joints, seams, and notches in sheet metal.Pattern Development: Sheet Metal Level 4 . Advanced Pattern Development By this time in your training, we are looking at advanced pattern development of various fittings. This will begin to introduce us to a combination of methods and techniques and using them together in a process to create these types of fittings. It is essential to bring a .

Title: Pattern Development : Sheet Metal Level 1: Authors: Coey, Brian: Keywords: Metal manufactures, metalworking: Issue Date: 13-Aug-2021: Publisher:

This chapter discusses pattern development, which is used to design industrial products and packaging. It explains that pattern development involves laying out an object on a single flat plane from which patterns can be cut and formed into the final shape. The chapter objectives are to explain how pattern development is used, identify methods for processing sheet metal .

Parallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an object are indeed parallel. The two ends of the part must be the same.

The flat pattern development of sheet metal components is a prerequisite for sheet metal fabrication. The conventional graphic solution or the analytical method carried out manually is laborious . A textbook on sheet-metal pattern drafting by International Correspondence Schools. Publication date 1901 . PDF download. download 1 file . SINGLE PAGE PROCESSED JP2 ZIP download. download 1 file . TORRENT download. download 22 Files download 10 Original. SHOW ALL. IN COLLECTIONS .Title: Practical sheet metal work and demonstrated patterns Created Date: 12/13/2012 3:35:07 PMParallel Line Development. The process of pattern development is the way we turn 2D sheets of metal into 3D objects. A parallel line is one of the basic forms of layout. We use it when element lines (bends) on an object are indeed parallel. The two ends of the part must be the same.

the blank required to form the desired sheet metal component. Flat Pattern Development (FPD): It is the process of determining flat pattern for a sheet metal component corresponding to its neutral surface. The neutral surface is the surface within the sheet that is parallel to the inner and outer surfaces and on which the net stress of the .

sheet metal layout software free

In Parallel Line Pattern Development, we required parallel element line or bends. Some objects are of a conical shape and parallel line will not work on them. Rather, we will look at using Radial Line Pattern Development. In radial line, we develop patterns for shapes that have a taper, all element lines (bends) must radiate back to a common .Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .

The new metal worker pattern book; a complete course of instruction in the modern methods of developing and cutting the patterns for sheet metal work, giving the principles under-lying practically every problem that is likely to come up in practice and explaining the selection and use of drawing tools and linear and geometrical drawing so clearly that one who has had .Pattern-Development-Sheet-Metal-Level-1-1628880196 - Free download as PDF File (.pdf), Text File (.txt) or read online for free.Pattern Development: Sheet Metal Level 1. Introduction When wanting to build a project, we need to first imagine it. The process of pattern development gives us the ability to take that visual representation and actually create the object. It allows us to turn two-dimensional metal, into three-dimensional objects, which is the basis for . For sheet metal components, there are a few papers on feature recognition and feature-based design, but all systems use 3-D models [12], [13], [14], [15].Apart from the feature recognition, flat pattern development is also an essential step to develop process plans for sheet metal components.

Design Checkpoint: Why Use Sheet Metal? 4 Tolerances 4 Xometry’s Sheet Metal Tolerance Offerings 5 Geometry-Dependent Tolerances 6 Typical Stock Size and Gauge 6 Sheet Stock Sizes and Gauge Lookup Chart 7 Stock Material Thickness Tolerances 8 Quoting Formats: 3D CAD and DXF Files 9 DXF Requirements 10 General Design Tips 11 Wall Thickness 12 .Starting a New Sheet metal File 1. To start a new sheet metal file, click Get Started Launch > New on the ribbon. 2. On the Create New File dialog, click the Sheet Metal.ipt icon, and then click Create. Setting the Parameters of the Sheet Metal part 1. To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the SheetSurface development is a full size layout of an object drawn on a plane. Some objects are made of flat sheet metal. When the sheet is cut as per this layout, folded and joined together, it takes the shape of an object. Orthographic projections of the object are drawn first and then the development is drawn.

Pattern development is used in sheet metal and packaging industries. In sheet metal, patterns are used to cut and form metal sheets into objects like ducts and pans through bending and fastening. In packaging, patterns allow designers to create durable and appealing boxes and containers that protect fragile contents. Patterns are surface .Sheet Metal Drawing & Pattern Development by Alfred Dickason, February 1983, Sportshelf & Soccer Associates edition, Paperback in EnglishPattern Development: Sheet Metal Level 1. Parallel Line Pattern Development. 15 Equal Diameter 90 Degree Tee We can start to take some short-cuts in our drawing. Instead of drawing a full plan view, we will use profiles. You can always go back to drawing the full plan view!

From the shop drawing, create an end view of the fitting; In the end view, label each piece with the amount of “drop” it has; Look for the corner which appears as “dot”.The dot will show where a bend can occur and will have no slope . Calculate the blank size for this piece. With no slope, it is merely the given length and the perimeter around the 2 sides

Tips for Using This Textbook. Search the textbook.. If using the online webbook, you can use the search bar in the top right corner to search the entire book for a key word or phrase.22 Frustum of a Cone . Draw an elevation view, including the apex point.; Profile the base of the elevation view and divide it into 6 equal parts.; Label the profile from 1 to 7 and project the divisions vertically into the base of the cone. Project the element lines from the base to the apex of the cone.; Locate a radius point where you want to develop the pattern.PDF No Computer, print copy Adobe Reader (for reading on a computer) or a printer Ability to highlight and annotate the text. If reading on the computer, you can zoom in. Static images instead of animations. EPUB No Computer, tablet, phone • . Pattern Development: Sheet Metal Level 1. Pattern Development: Sheet Metal Level 1Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both parallel line and radial line pattern development, we saw fairly simple and limited layout process. We have conditions that must be met in order to use them. Triangulation is the process used when nothing else works. There are very few conditions in which .

sheet metal fabrication hand tools uk

Where I can really smell it is either by smelling the exhaust pipe from the outside of the house when the unit is not running OR if I open up the furnace cover and smell around the burner chamber. I'm 99% confident though that this smell is not gas.

sheet metal pattern development pdf|sheet metal fittings layout drawing