is metal fabrication dangerous Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal. A mud ring would look like this (thanks to homedepot.com for the image): The difference is that the mud ring simply holds the device in place; it does not count as a "cover" because it does not keep fingers and objects .

0 · welding fabrication hazards

1 · sheet metal fabrication safety

2 · safety of metal fabrication

3 · osha metal fabrication

4 · metal fabrication safety requirements

5 · metal fabrication safety hazards

6 · metal fabrication safety clothing

7 · dangers of metal fabrication

CNC machining is a manufacturing process that relies on computerized controls to guide the movement of cutting tools and other machinery in the fabrication of parts from raw materials.

welding fabrication hazards

heavy metal haunted house

sheet metal fabrication safety

Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal.Health hazards from welding, cutting, and brazing operations include exposures to metal fumes and to ultraviolet (UV) radiation. Safety hazards from these operations include burns, eye . Working in the metal fabrication field can be dangerous unless the person knows what they are doing. Loss of concentration can occur because of noise and other distractions .

Knowing how to keep your shop compliant with OSHA regulations can prevent injuries, save lives, and protect your company’s bottom line. Here are the top five OSHA citations with the highest penalties in fabricated metal product . Welding, brazing and cutting are some of the most dangerous tasks in commercial metal fabrication. The processes create fumes, some level of radiation and other hazards. OSHA has in place a full set of safety regulations . Whether you currently work in this industry, or if you're looking to enter it, you should familiarize yourself with the common injuries and health risks of sheet metal fabrication. .

Knowing how to keep your metal fabrication shop OSHA-compliant and modeling a culture of safety will reduce the risk of costly worker injuries and production downtime, and help your shop avoid fines and shutdowns associated with lax . If you’re looking to curb recurring incidents for your metal work and fabrication workers, here are four issues you should focus on. Lack of guards and other protection. The working environment in any metal fabrication plant has .

heavy metal house hufft projects

The metal fabrication process involves dealing with raw, rough and rugged metal components which are then cut, bent, welded and assembled to form desired metal structures. The main involvement of complex, engaging and intense . Yes, metal fabrication is an excellent career path. There are many different paths you can take in this field, be it in construction, heavy machinery operation, or studying metallurgy. . Heavy machinery requires skilled . Metal fabrication is a vital component of many industries, from construction to automotive manufacturing. However, working with metal fabrication equipment and materials can be dangerous if not handled properly. . 5 careers in metal fabrication These are some of the careers you can pursue in metal fabrication: 1. Welder National average salary: ,766 per year Primary duties: Welders specialize in joining multiple metal parts by using a device that produces intense heat. They either operate it by hand or use specialized machinery to cut metal parts to specific shapes and sizes .

Workers in the metal fabrication industry are often exposed to high-risk activities, such as welding ferrous materials. A single day on the job in a metal fabrication facility will quickly and visibly show you the frequency in which dangerous tasks are carried out in tandem. . Some of the most dangerous machinery cited include mechanical . Metal fabrication is an integral part of many different industries, and it can be one of the most dangerous due to the tools and techniques necessary to complete each task. Metal shop injuries are often extreme and can be even fatal in some situations. Some welding fume components and welding processes can be especially dangerous in a short period of time. Cadmium in welding fumes can be fatal in a short time. . The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable .

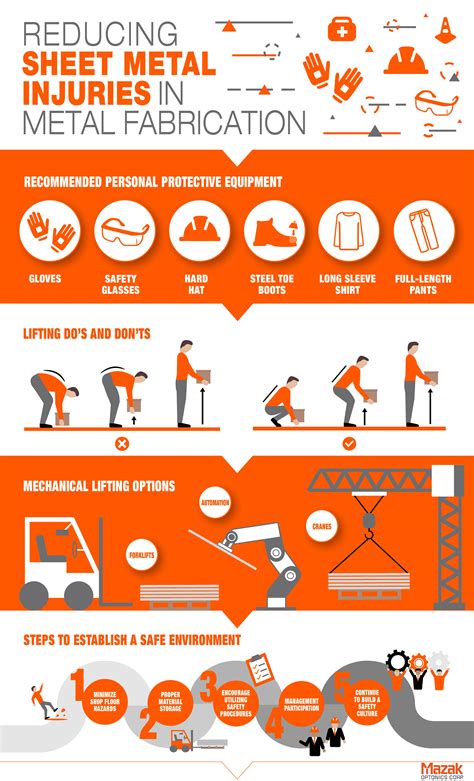

Metal fabricators typically need eye and face protection from flying particles, molten metal, liquid chemicals, chemical gases or vapors, harmful light radiation, and infectious materials. . Welding, cutting, and brazing are exceptionally dangerous. Welding creates fumes, radiation, and other hazards. OSHA has a full set of regulations .

Working in the metal fabrication field can be dangerous unless the person knows what they are doing. Loss of concentration can occur because of noise and other distractions and result in the employee sustaining an injury. The mishandling of materials often causes both minor and major injuries. Misuse of tools and machinery is another cause of .

In normal metal fabrication dangerous sharp burrs are created. Someone along the assembly line is supposed to remove those dangerous sharp burrs by grinding or sanding. Then someone else down the assembly line is supposed to check to be sure that the first person actually removed all the sharp burrs. Both of those people failed at their jobs .

The metal fabrication industry as you probably already know consists of a lot of cutting, grinding, welding, metal bending. Operating very dangerous machinery that might not seem as dangerous on the first look.

That’s especially true if they perceive them as dirty or dangerous or if family members or peers push them toward other options. The American Welding Society estimates a 400,000-worker shortage by 2024. . Dealing with the metal fabrication skills shortage requires more than giving people the foundational know-how they need to get started in . Metal fabrication equipment is inherently dangerous; a single mistake could easily lead to injury or even death. One of the easiest ways to make working in a metal fabrication shop safe is to implement a few simple rules that’ll help you carry out your job efficiently and reliably. With the upswing in business, shops are likely adding new materials and operations to the shop floor mix. This can increase the potential for a combustion event and add challenges to mitigating strategies. A fab shop owner or manager needs to take the time to review the manufacturing processes, understand the risks posed by the dust and the process, and .About Your vision, our precision; let’s make the impossible possible through CNC innovation! Unity Manufacture is a premier CNC manufacturing workshop specializing in custom-made CNC parts for various industries. With state-of .

Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves .

of welding fabrication safety related to the areas of light metal. You must read, learn, and follow all safety rules, regulations, and procedures for those areas. Light welding fabrication, like all other areas of welding work, has a number of potential safety hazards. These hazards need not result in anyone being injured.Loose clothing can be dangerous because it can get trapped in heavy equipment. This could lead to a number of life-threatening injuries or even amputations in the worst-case scenario. . Metal fabricators are no stranger to the risks involved in this trade, which is why they know all the safety risks and hazards that may happen to them . The equipment used in metal fabrication work can be dangerous if used incorrectly. The finished product often is used in difficult environments, and a finished product that fails can cause hazards. Taking a little extra time to think through what metal fabrication tips and tricks to use can prevent injury and save time and money. 1. Work .

Many newer robots come with advanced safety features that can make metal fabrication plants less dangerous for workers. For example, light curtains or motion-detecting tools can automatically shut down a working machine when an employee comes within an unsafe distance. Some collaborative robotics come with cushions or force-limiters that can . Rich Marker All Metals Fabrication Owner and CEO. Rich Marker is an 18 year, skilled professional in metal fabrication and manufacturing. Co-founder, owner and principal of All Metals Fabrication, Rich has helped to sustain the company’s success over a variety of economic conditions.He has extensive background in continuous improvement, training and process .

In the metal fabrication industry, for example, common risks that can be mitigated by protective equipment include metal fume inhalation, airborne silica, molten metals, chemicals, heat, and falling hazards. These hazards may require equipment for respiratory protection, eye and face protection, hand protection, foot protection, and more.

In metal fabrication, blueprint reading enables us to understand the design specifications, ensuring precision in cutting, bending, or welding metals. . Safety is the cornerstone of any industrial job, especially one involving heavy machinery and potentially dangerous materials like in metal fabrication. Employers want to know that their .

Metal fabrication involves transforming raw metal materials into usable products through processes such as cutting, shaping, bending, assembling, and finishing. . they can also be very dangerous. Standard safety precautions in these environments include: Wearing appropriate safety equipment: This includes flame-resistant pants and jackets .

Engineers at Metal-craft are detail-oriented, and customer service focused. . contrasts the science of the storage product with engineering materials and processes to ensure the elimination of dangerous attributes for efficient functioning of the storage product. Our tanks are corrosion resistant; built and engineered from premium quality . Breathing In Sheet Metal Dust. A lesser-known danger of working with sheet metal is the potential for breathing in tiny particles of dust. These particles will gather in the lungs where they increase an worker's risk of respiratory illness and disease. Sheet Metal Fabrication Safety Tips: ALWAYS wear heavy-duty gloves when handling sheet metal. The metal fabrication industry is expected to experience significant transformation in the coming years. Take into the following trends to go ahead in the market! 3D printing and additive manufacturing; 3D printing or additive manufacturing utilizes a CAD model or a digital 3D model to create a three-dimensional object. It deposits, joins, or .

Key areas of focus include the need for thin steel sheet metal production as well as other high-demand metals including aluminum, copper, and tin. According to PR Newswire the global metal fabrication market is largely on the rise, and the industry will grow by billions of dollars by 2027.

is metal fabrication dangerous|welding fabrication hazards