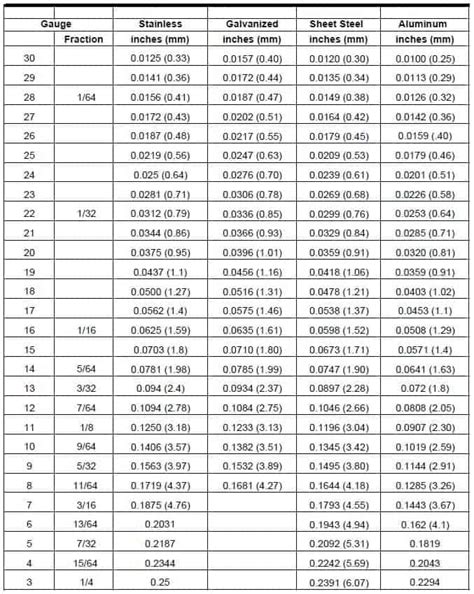

how is sheet metal gauge determined The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter. $8.49

0 · steel gauge thickness chart

1 · sheet metal thickness chart wikipedia

2 · sheet metal gauge chart excel

3 · sheet metal gauge chart

4 · sheet metal gages vs thousands

5 · most common sheet metal gauge

6 · metal measurement chart

7 · difference between gauge and thickness

$249.99

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.Pure metal / Used as an alloy element for aluminum, lead, zinc, and other .

The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value. Standard gauge sizes were developed based on the weight of the sheet for a given material and the . A sheet metal gauge is a standard unit of measure used to determine the thickness of a metal sheet. The gauge number and thickness have an inverse relationship – the higher . A sheet metal gauge chart provides essential information that lets you choose accurate material measurements in construction, manufacturing, and engineering. Using these charts can help you enhance the quality of your . To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar .

A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for . Here is what you need to know: The numbers of a steel gauge chart typically range between 3-30. Yet those numbers do not indicate a specific dimensional value. .A sheet metal gauge chart serves as a valuable tool for understanding the thickness of sheet metal materials. By providing a standardized measurement system, it allows users to quickly determine the thickness based on gauge .

How are Sheet Metal Gauges Used? Gauges are used to specify the thickness of a sheet metal. Gauges are neither standard nor metric and the values are independent of those measurement systems. A gauge conversion .Lower gauge numbers identify thicker sheets of metal. As gauges increase, metal sheets get thinner. Not all types of metals use the same gauge system. Aluminum and other nonferrous metals use the Brown and Sharpe system (also known . The higher the gauge, the wider the sheet metal screw. Length. Don’t forget to check the length when choosing sheet metal screws. The gauge only reveals how wide a sheet metal screw is; the gauge doesn’t reveal its .Engineers may need a steel gauge chart to determine the required dimensions of the material to be machined, to understand the gauge system and familiar with the thickness for specific gauge such as 16 gauge thickness, here we’ll explain .

Sheet metal gauge is based on how many sheets stacked up make an inch. So a 12 gauge sheet is 1/12 inch, a 16 gauge sheet is 1/16 inch, etc. . They’re different units of measurements. A firearm gauge is determined from the weight of a solid sphere of lead that will fit inside the barrel. So for a 10 gauge, a 1/10th lb ball fits in the gun. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for accurate material selection and processing. . Through iterative process optimization, the wire industry determined the .

On the other hand, if you wish to determine the sheet metal gauge of ferrous metals (iron-containing metals) like cast iron, stainless steel, etc., ensure to choose a gauge wheel that reads “ferrous metal.” Use the right gauge wheel . Sheet metal gauges are critical tools in manufacturing. Explore their uses, types, affecting factors, and advantages. Services. Machining Service. . The performance and effectiveness of the manufactured project and the sheet’s workflow are determined by the ideal thickness of the sheet. Therefore, the engineer must consider performance and .Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the number, the smaller the diameter, and now it is also used to indicate the . A sheet metal gauge chart uses the thickness and weight per area of different metals to determine standardised thicknesses or ‘gauges’. The higher the gauge, the thinner the sheet. Selecting the correct thickness is a critical part of .

The gauge indicates the standard thickness of the sheet metal for a specific material. As the gauge number increases, the material thickness decreases. When it comes to metal fabrication, metal thickness based on gauge is an important element. This Gauge Chart is vital when it comes to choosing the correct metal thickness and components for .Discover the importance of steel gauge charts and how to use them effectively. Keeping a gauge conversion chart nearby is an easy way to determine the actual thickness of a sheet of metal in inches or millimeters. For example, a 14 gauge aluminum sheet is 0.0641 inches thick, In millimeters, it is 1.628mm. The gauge number 14 holds no relevance to the actual measurements. 16 gauge aluminum sheet is 0.0508 inches thick, In .

alcove over the bed metal organizer with fabric baskets

Study with Quizlet and memorise flashcards containing terms like true or false, a double hymn requires two folding operations?, true or false, the width of the bend is limited in a bar folder?, allowance for metal thickness is not required when making seams of what gauge or lighter on a bar folder? and others.

steel gauge thickness chart

We would like to show you a description here but the site won’t allow us.

Using a gauge conversion chart allows individuals to accurately determine the thickness of sheet metal, irrespective of the specific gauge system or metal type being used. This information is . A metal gauge thickness chart provides a standardized reference for the various thicknesses of metal sheets and plates, allowing you to select the right material for your specific application. . The concept of ‘gauge’ refers to the standard measurement used to quantify the thickness of sheet metal; however, it can be somewhat confusing as .This is where a sheet metal gauge chart comes into play. In this article, we will explore the significance of a sheet metal gauge chart and provide insights into its interpretation for effective decision-making. . Construction: Builders and .

all cnc machines use the same programming language.

The exercise I went through to figure out if doubling 30-gauge sheet metal would work involved converting 24 gauge to mm (.701 for galvanized), . But the numbers, though may be arbitrary, they are set in .What gauge sheet metal should I use? Well When we talk about gauge in sheet metal fabrication, we're talking about the typical thickness of sheet metal for a particular material. As a result, the gauge of sheet metal material is what you should look for if you want to know how thick it is. The material's thickness is determined by the gauge number. Sheet Metal Gauge is a setting SOLIDWORKS parts are assigned as soon as the first sheet metal feature is created. It's easy to create and manage multiple variations of similar parts or assemblies using configurations. We frequently configure the values of dimensions, the suppression state of features, and part materials. Sheet metal parts are no different, and we . Before the standard and metric measurement systems were widely used, it probably came from the British wire business. Gauges were used to measure the size of the metal wire being pulled at the time. Since then, it has been a common way to show the thickness of wire and metal sheets. Sheet Metal Gauge Charts. Use these sheet metal gauge charts .

Sheet Metal Gauge Vs. Metal Gauge. At first glance, the terms "sheet metal gauge" and "metal gauge" might seem interchangeable. However, there's a subtle distinction. While the former specifically refers to flat pieces of metal, the latter encompasses various forms, including wires and rods. The term "gauge steel" is often used to refer to the . Sheet Metal Gauge: Using, Affecting Factors & Advantages How is sheet metal gauge determined? Sheet metal gauge chart. Handbook: the complete guide to steel gauge chartClick image for larger version name: gauge_chart.jpg views: 5941 size Aluminum sheet: aluminum sheet gauge tablePrintable sheet metal gauge chart. By knowing the weight of the gauge of steel you are working with, you can determine the thickness. 1. Identify the Type of Steel. . But the sheet metal gauge to mm formula isn't difficult, either. Advertisement. As shown above, find the thickness in inches. To convert from inches to millimeters, use the conversion factor of 25.4 mm=1 inch . How is sheet metal gauge determined? .. Sheet metal gauge to mm - Gauge to Thickness Chart Download. Check Details. Appendix - Engineering Design Graphics with Autodesk Inventor 2020 [Book] Check Details. Printable Sheet Metal Gauge Chart. Check Details. Guide to Understanding Gauge Thickness - SendCutSend

Now moving into something that will be more specific to each customer and each sheet metal project. This is choosing the right thickness, or gauge, of sheet metal. It is very important that you are using the correct product to optimize efficiency and functionality. In order to measure the sheet metal, you will need a sheet metal gauge handy! Understand how sheet metal gauges work and use these conversion charts to help determine the gauge you need. How is sheet metal gauge determined?Gauge sheet metal determined Gauge sheet chart metal thickness aluminum gage steel table metric mm thicknesses gtsparkplugs decimal inches gauges size stainless guide equivalentHandbook: the complete guide to .

sheet metal thickness chart wikipedia

Underfloor Trunking is designed to be positioned on a concrete slab and completely covered by the floor screed. U-LI junction boxes are specially designed to facilitate cabling management in high rise buildings. U-LI junction boxes consists of three main features:

how is sheet metal gauge determined|most common sheet metal gauge