cnc glass corner machine One machine equipped with 8 sets of positioning piles. DB polishing wheel can automatically compensate electric pressure, wheels compensation automatically. Delta servo motor and . Sheet & plate metal fabrication & general machining shop, including CNC milling & turning, 5-axis machining, large surface grinding, welding & CMM inspection services. United Machine & Metal Fabricators, Inc. is located in Conover, NC and is a supplier of Machine Work & Machining.

0 · Precision CNC Glass Machining

1 · High Efficiency Glass CNC Machine

2 · Glass Corner Radius Grinding CNC Machine

3 · Glass CNC working center

4 · GPC

5 · CNC Glass Corner Edging Machine

6 · CNC Edge Grinding and Seaming Machines From

7 · CNC CORNER

A comprehensive breakdown of SMART sheet metal workers salary and benefits across North America, complete with cost of living adjustments.

Fully Automatic, CNC Glass Corner Radius Grinding and Polishing Machine for 3mm to 40mm thickness Glass from 2 to 80mm corner radius. Straight or Pencil Edge as per requirement. Advanced technology ensures .CNC Glass processing center is designed for edging, drilling, milling and polishing process for straight and shape glasses. The PC based numerical control work center is dedicated to the glass processing.

inline solar junction boxes

CNC glass edging and polishing machine for glass corners. Fully automatic and can integrate into production lines.One machine equipped with 8 sets of positioning piles. DB polishing wheel can automatically compensate electric pressure, wheels compensation automatically. Delta servo motor and .In the end, the team at GLASSLINE produce a robust, reliable, efficient CNC grinding machine for glass shapes. Our approach is to provide proven machines that best meet our Customer’s needs, at a reasonable price.

Precision CNC Glass Machining. Cat-i Glass is in the forefront of tight tolerance, high volume CNC glass processing. Cat-i engineers have developed many of the glass grinding techniques and machinery used throughout the industry.

install metal electrical box ts bracket for 1 2 drywall

CNC1510 is a compact multifunctional CNC working center with 3 digital interpolated axes specifically designed for the small and medium size shop aiming to perform .PC based numerical control, can edge/polish two corners at the same time, ideal for batch & scatter glass. The single spindle can handle both grinding and polishing operations. Easy to operate Windows interface. Fully Automatic, CNC Glass Corner Radius Grinding and Polishing Machine for 3mm to 40mm thickness Glass from 2 to 80mm corner radius. Straight or Pencil Edge as per requirement. Advanced technology ensures efficient and effective testing processes.CNC Glass processing center is designed for edging, drilling, milling and polishing process for straight and shape glasses. The PC based numerical control work center is dedicated to the glass processing.

innovative storage designs 2 drawer steel file cabinet

CNC glass edging and polishing machine for glass corners. Fully automatic and can integrate into production lines.

One machine equipped with 8 sets of positioning piles. DB polishing wheel can automatically compensate electric pressure, wheels compensation automatically. Delta servo motor and servo drive. Delta high-speed spindle frequency conversion drive & frequency converter.In the end, the team at GLASSLINE produce a robust, reliable, efficient CNC grinding machine for glass shapes. Our approach is to provide proven machines that best meet our Customer’s needs, at a reasonable price.Precision CNC Glass Machining. Cat-i Glass is in the forefront of tight tolerance, high volume CNC glass processing. Cat-i engineers have developed many of the glass grinding techniques and machinery used throughout the industry. CNC1510 is a compact multifunctional CNC working center with 3 digital interpolated axes specifically designed for the small and medium size shop aiming to perform the largest variety of jobs in the easiest and most seamless manner.

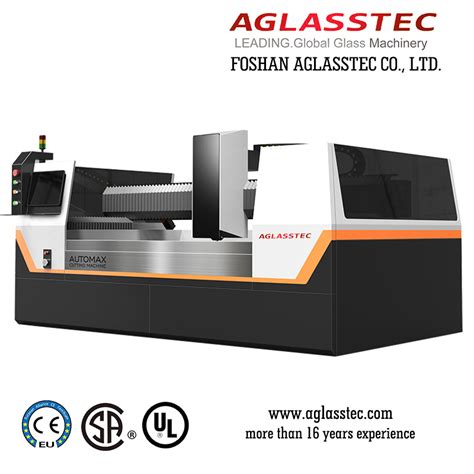

Aglasstec (Leading Global Glass Machinery) is specialized in research and developing glass edging solutions since 2009, all these years we developed all kind of edging solutions, include Single Edger, double edger, four side seaming and edging, manual cross belt machine for seaming, auto CNC shape edger, manual shaper edger, corner edging .

Our heavy duty glass CNC corner edging machines are suitable to edge and polish corners of any glass or mirror products. The machines are designed considering the long term working period, with very user friendly operations and all come with a 1 year warranty.

PC based numerical control, can edge/polish two corners at the same time, ideal for batch & scatter glass. The single spindle can handle both grinding and polishing operations. Easy to operate Windows interface. Fully Automatic, CNC Glass Corner Radius Grinding and Polishing Machine for 3mm to 40mm thickness Glass from 2 to 80mm corner radius. Straight or Pencil Edge as per requirement. Advanced technology ensures efficient and effective testing processes.

Precision CNC Glass Machining

High Efficiency Glass CNC Machine

CNC Glass processing center is designed for edging, drilling, milling and polishing process for straight and shape glasses. The PC based numerical control work center is dedicated to the glass processing.CNC glass edging and polishing machine for glass corners. Fully automatic and can integrate into production lines.

One machine equipped with 8 sets of positioning piles. DB polishing wheel can automatically compensate electric pressure, wheels compensation automatically. Delta servo motor and servo drive. Delta high-speed spindle frequency conversion drive & frequency converter.

Glass Corner Radius Grinding CNC Machine

In the end, the team at GLASSLINE produce a robust, reliable, efficient CNC grinding machine for glass shapes. Our approach is to provide proven machines that best meet our Customer’s needs, at a reasonable price.Precision CNC Glass Machining. Cat-i Glass is in the forefront of tight tolerance, high volume CNC glass processing. Cat-i engineers have developed many of the glass grinding techniques and machinery used throughout the industry. CNC1510 is a compact multifunctional CNC working center with 3 digital interpolated axes specifically designed for the small and medium size shop aiming to perform the largest variety of jobs in the easiest and most seamless manner.

Aglasstec (Leading Global Glass Machinery) is specialized in research and developing glass edging solutions since 2009, all these years we developed all kind of edging solutions, include Single Edger, double edger, four side seaming and edging, manual cross belt machine for seaming, auto CNC shape edger, manual shaper edger, corner edging .

inspector did not look at junction boxes

install metal switch box old work

UNDERMOUNT INSTALLATION: Sink is installed beneath the countertop creating a seamless appearance between the sink and the countertop. LARGE CAPACITY: Straight sidewalls give the sink a flat bottom and offer more usable space for stacking, soaking and .

cnc glass corner machine|CNC CORNER