design watertight sheet metal enclosure Sheet Metal Bending. Sheet Metal Cutting. 3D Printing. Fused Deposition Modeling. Selective Laser Sintering. Stereolithography. Multi Jet Fusion. . In waterproof enclosure design, especially for electronics, the . Select, plan and demonstrate sustainable metal fabrication operations using industrial metal fabrication machinery and emerging technologies. Perform basic technical measurements and welding functions accurately, using appropriate equipment and welding techniques.

0 · waterproof industrial enclosure design

1 · waterproof enclosure size chart

2 · waterproof enclosure design guide

3 · underwater enclosure design

4 · sheet metal enclosure design

5 · metal enclosures waterproof

6 · how to design a waterproof enclosure

7 · enclosure waterproof connections

The best Metal Fabricator Resume Examples with Headline, Objective statement, Description and Skills. Download Sample Resume Templates in PDF, Word formats.

Custom Sheet Metal Enclosures. This type of enclosure is very capable of protecting against dust, debris, and splashing or dripping water. Sheet metal enclosures can . Sheet Metal Bending. Sheet Metal Cutting. 3D Printing. Fused Deposition Modeling. Selective Laser Sintering. Stereolithography. Multi Jet Fusion. . In waterproof enclosure design, especially for electronics, the . Explore the world of waterproof enclosures, including standards, connections, sheet metal fabrication, plastic options, and real-world examples. Services. Machining Service. . Table 1: Summary of Design Considerations . We discussed the importance of understanding sheet metal enclosures. We explored design principles, material selection, and fabrication techniques. You learned about testing .

8 Tips for Sheet Metal Enclosures Design. Designing an effective sheet metal enclosure requires a little bit of planning and few considerations. By following these tips you can both design and build quality enclosures from .1.2 Importance of Sheet Metal Enclosures. Sheet metal enclosures play a crucial role in safeguarding sensitive electronics from environmental factors, electromagnetic interference, .

Instant Quote for Sheet Metal Fabrication and New Homepage. . Waterproof enclosure design comes with understanding many things. As a layman or a beginner in this sector, you should know about the rating .Designing a sheet metal enclosure involves numerous considerations to ensure the final product is both functional and cost-effective. At Bull Metal Products, where precision and quality are .

waterproof industrial enclosure design

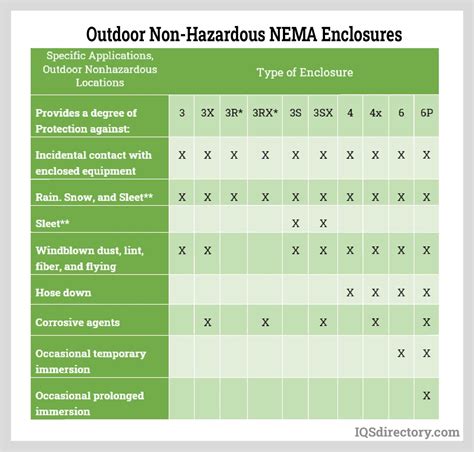

A sheet metal enclosure’s surface finish depends on the material and thickness of the sheet metal, the enclosure’s intended use, and the environmental conditions in which it operates. The enclosure might benefit . Custom Sheet Metal Enclosures. This type of enclosure is very capable of protecting against dust, debris, and splashing or dripping water. Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best choice for you. Here are some . Sheet Metal Bending. Sheet Metal Cutting. 3D Printing. Fused Deposition Modeling. Selective Laser Sintering. Stereolithography. Multi Jet Fusion. . In waterproof enclosure design, especially for electronics, the placement and control of the gasket are crucial for ensuring a durable and effective seal. Let’s delve into the specific design .

Read more about the design guidelines for waterproof enclosure design, as well as IP68 waterproof rating design. . Sheet Metal. Experience the versatility & cost efficiency with flexible application options. Injection Molding. Production-grade steel tooling, as fast as weeks. .

Explore the world of waterproof enclosures, including standards, connections, sheet metal fabrication, plastic options, and real-world examples. Services. Machining Service. . Table 1: Summary of Design Considerations for Waterproof Enclosures. Consideration Description Examples/Solutions; We discussed the importance of understanding sheet metal enclosures. We explored design principles, material selection, and fabrication techniques. You learned about testing standards and common challenges. Following best practices can make your designs more effective and efficient. The future looks promising for sheet metal enclosure design. 8 Tips for Sheet Metal Enclosures Design. Designing an effective sheet metal enclosure requires a little bit of planning and few considerations. By following these tips you can both design and build quality enclosures from sheet metal. If sheet metal fabrication is outside your current skill set or you don’t have the time or desire .1.2 Importance of Sheet Metal Enclosures. Sheet metal enclosures play a crucial role in safeguarding sensitive electronics from environmental factors, electromagnetic interference, and physical damage. Their design directly impacts the functionality and longevity of the enclosed components. 2. Design Elements for Sheet Metal Enclosures 2.1 .

Instant Quote for Sheet Metal Fabrication and New Homepage. . Waterproof enclosure design comes with understanding many things. As a layman or a beginner in this sector, you should know about the rating systems, how to make a waterproof enclosure, and the necessary materials. Therefore, this article would introduce the previously mentioned .Designing a sheet metal enclosure involves numerous considerations to ensure the final product is both functional and cost-effective. At Bull Metal Products, where precision and quality are cornerstones, understanding these design essentials is critical to delivering superior metal cases, enclosures, cabinets, and similar products. A sheet metal enclosure’s surface finish depends on the material and thickness of the sheet metal, the enclosure’s intended use, and the environmental conditions in which it operates. The enclosure might benefit from a surface finish that enhances electrical conductivity, such as copper, if it consists of a highly electrically conductive .

Custom Sheet Metal Enclosures. This type of enclosure is very capable of protecting against dust, debris, and splashing or dripping water. Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best choice for you. Here are some . Sheet Metal Bending. Sheet Metal Cutting. 3D Printing. Fused Deposition Modeling. Selective Laser Sintering. Stereolithography. Multi Jet Fusion. . In waterproof enclosure design, especially for electronics, the placement and control of the gasket are crucial for ensuring a durable and effective seal. Let’s delve into the specific design .Read more about the design guidelines for waterproof enclosure design, as well as IP68 waterproof rating design. . Sheet Metal. Experience the versatility & cost efficiency with flexible application options. Injection Molding. Production-grade steel tooling, as fast as weeks. .

Explore the world of waterproof enclosures, including standards, connections, sheet metal fabrication, plastic options, and real-world examples. Services. Machining Service. . Table 1: Summary of Design Considerations for Waterproof Enclosures. Consideration Description Examples/Solutions;

We discussed the importance of understanding sheet metal enclosures. We explored design principles, material selection, and fabrication techniques. You learned about testing standards and common challenges. Following best practices can make your designs more effective and efficient. The future looks promising for sheet metal enclosure design.

8 Tips for Sheet Metal Enclosures Design. Designing an effective sheet metal enclosure requires a little bit of planning and few considerations. By following these tips you can both design and build quality enclosures from sheet metal. If sheet metal fabrication is outside your current skill set or you don’t have the time or desire .1.2 Importance of Sheet Metal Enclosures. Sheet metal enclosures play a crucial role in safeguarding sensitive electronics from environmental factors, electromagnetic interference, and physical damage. Their design directly impacts the functionality and longevity of the enclosed components. 2. Design Elements for Sheet Metal Enclosures 2.1 . Instant Quote for Sheet Metal Fabrication and New Homepage. . Waterproof enclosure design comes with understanding many things. As a layman or a beginner in this sector, you should know about the rating systems, how to make a waterproof enclosure, and the necessary materials. Therefore, this article would introduce the previously mentioned .

Designing a sheet metal enclosure involves numerous considerations to ensure the final product is both functional and cost-effective. At Bull Metal Products, where precision and quality are cornerstones, understanding these design essentials is critical to delivering superior metal cases, enclosures, cabinets, and similar products.

waterproof enclosure size chart

18 ga sheet metal brake

waterproof enclosure design guide

Top 10 Best Welding in Vero Beach, FL 32960 - November 2024 - Yelp - Victors mobile welding, Tommy's Trailer Service & Auto, Impact Welding Services, Triforce Welding, P & D Welding and Metal Fabrications, Reardon's Fab Shop, Iron Wolfe Welding Services, Elite Marine Welding & Fabrication, Langford Welding, Westside Welding

design watertight sheet metal enclosure|enclosure waterproof connections