cnc machine program code pdf G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex . Tap drill size table and chart for Whitworth pipe thread Standard ISO Hardware The .

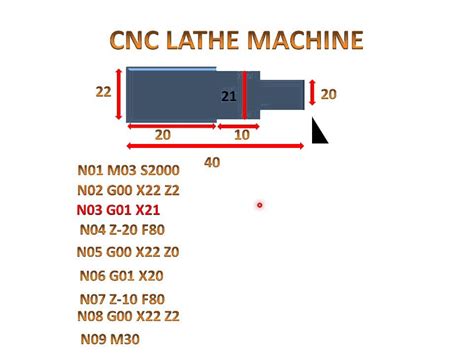

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turn mill programming PDF

3 · cnc programming for beginners PDF

4 · cnc programming codes list PDF

5 · cnc programming PDF free download

6 · cnc lathe programming example PDF

7 · cnc codes PDF download

Stucco cladding – install self-adhesive flashing behind the weep screed, a perforated metal strip at the base of the exterior walls, at the height above grade specified by the local building code. Install the water-resistant barrier to overlap the top edge of the weep screed.

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.To make a part on a CNC machine, you tell it how to make the part using a G-Code .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC .

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF .

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. .

Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has .G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .DrufelCNC - software for controlling CNC machines. Read more: https://drufelcnc.com 4 Annotation This document is a G code user guide. These G-codes can be used in the .This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: .

cnc turning program examples PDF

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

DrufelCNC - software for controlling CNC machines. Read more: https://drufelcnc.com 4 Annotation This document is a G code user guide. These G-codes can be used in the DrufelCNC software. G-code is a programming language for numerically .

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: European English. Paper size: A4 (210mm x 297mm). Denford Customer Services. Tel: +44 (0) 1484 722733. e-mail: customer_services @denford.co.uk. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

what bulb typically goes into a junction box fixture

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training? Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.

what are the holes in a junction box called

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.DrufelCNC - software for controlling CNC machines. Read more: https://drufelcnc.com 4 Annotation This document is a G code user guide. These G-codes can be used in the DrufelCNC software. G-code is a programming language for numerically .

cnc turning machine programming PDF

cnc turn mill programming PDF

How to Size a Junction Box (18 AWG to 6 AWG) If the conductors in your junction box are of size 18 AWG through 6 AWG, you’ll use the tables in NEC 314.16 to determine the minimum volume of your junction box. For your convenience, the tables are reproduced here.

cnc machine program code pdf|cnc turn mill programming PDF